CNC Services. Whether you need a quick-turn, small production run of a bracket, or you’re looking for a larger run of an integral part for medical instrumentation, Roberson Machine Company is the place to turn for CNC services. Our experienced specialists operate our CNC machines efficiently and are comfortable in whatever situation best suits your project’s needs – rapid prototyping, small-batch machining, or high-volume production, thanks to automation and high repeatability.

Call us today to talk about your next CNC services project at 573-646-3996 or contact us online.

We operate every kind of CNC machine, and pride ourselves on being able to manufacture whatever you need, from basic, “as-machined” workpieces to complex, organic geometries with tight tolerances. We can also produce parts with wire EDM and grinders. We take our quality control standards seriously. We have internal standards that adhere to ISO 9001 and AS9100 certifications, ensuring our parts and processes are of the highest quality.

What Are the Benefits of CNC Services at Roberson Machine Company?

Roberson Machine Company takes the uncertainty out of manufacturing by ensuring the quality and consistency of every part, every time. The top 5 benefits of selecting Roberson Machine Company for your CNC services are:

- Accuracy — By using CAD and CAM software, a CNC machine can perform the most rigorous of cuts or measurements perfectly. Using our CNC turning or milling systems, our expert machinists can guarantee precise accuracy in prototyping or entire production runs.

- Repeatability — Our CNC services can produce large batches of accurate products. Each time. Every time. We maximize output and reduce waste, and pass along the savings to you.

- Flexibility — We specialize in operating multiple CNC machines at once. We frequently have customers that need varying sized materials. Our operators can quickly alter sizes via our CAD and CAM codes, allowing us to provide you with a large number of unique parts.

- Speed — Due to an extremely low risk of human error, the Roberson CNC machines complete production faster without affecting the quality of the finished product.

- Safety — Our expert machinists have 20-plus years of experience operating CNC machines. We follow strict rules and regulations, and we know what to be on the lookout for. All of our machines are enclosed with protective devices, and our specialists all wear the best protective gear. Our CNC machines are automated, meaning that while our skilled machinists are present and have programmed the CNC specs, they are not hands-on “on the machine.”

Utilizing CNC Services at Roberson Machine Company

Call us today at 573-646-3996 or contact us online. Our highly-regarded CNC services are:

CNC Milling

CNC milling is a subtractive manufacturing process. It starts by fixturing a block of metal or plastic material inside the CNC mill. Utilizing G-code, the CNC machine is programmed to rapidly mill out parts from the block of raw material. Our 3- and 5-axis CNC machines are equipped with various toolsets to maximize efficiency and production speed.

Types of materials ideal for milling include:

- Metals

- Aluminums:

- Stainless steel:

- Plastics:

- Aluminum

- Brass

- Low Carbon Steel

- Steel Alloy

- Stainless Steel

- Titanium

- Fast and Reliable Delivery

- Manufacturing Analysis and Online Quotes

- Infinite Capacity

- Material Selection

- Domestic, Centralized Production and Support

Machined plastic parts are left as-milled, meaning they typically show visible tool marks. Some metal parts allow more finishing choices like anodizing, laser engraving, and chromate coating. When the production run is complete and your required surface finish is applied, parts are boxed and ready to be shipped. Request a quick, free quote or call us now at 573-646-3996.

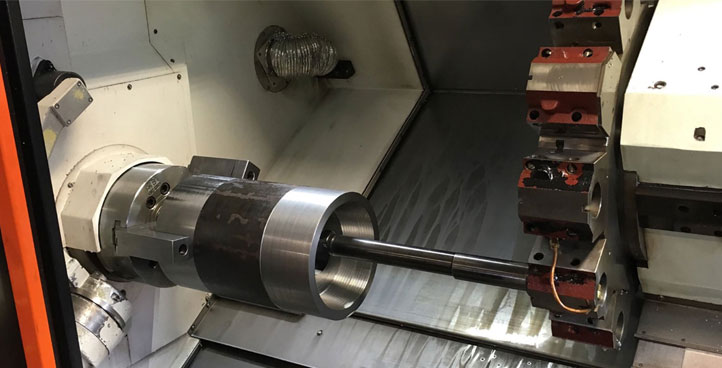

CNC Turning

A CNC lathe is normally used to perform/produce precise round (cylindrical or oblong) shapes with both an outer diameter and an inner diameter. A simple CNC lathe operates on two axes and the tool is located in a fixed position at 8 to 24 station turret. More advanced lathes have 3-axis, 4-axis, and 5-axis capabilities. The rotating action of the part is called “turning”, hence certain types of CNC lathes are called CNC turning machines. Extremely accurate, CNC turning can be used to turn out thousands of components that are each identical.

Parts that are turned have a very smooth surface finish. The as-machined surface finish of the cylindrical areas will typically be much smoother using the lathe than the mill, so consider this when selecting the machining method for those parts that qualify for either method. The metal parts can be lightly bead blasted, if you choose, leaving a fine matte finish.

We stock a wide range of metal materials ideal for your turned parts and their various applications and industries, including:

Why Choose Roberson Machine Company for Your CNC Services?

Customer satisfaction in our high-quality parts and services is our No. 1 goal. If you are not satisfied, neither are we. We want to create the best experience possible for you, to keep you coming back. Reasons why our customers choose us include:

We are ideally situated on our own land and in our own facilities, in a convenient and central location, for fast delivery times and access to major markets.

When you upload your CAD file to request a quote, our specialists will analyze your part geometry to identify any features that may be difficult to machine such as tall, thin walls or holes that can’t be threaded.

Eliminate downtime spent waiting for parts and safeguard in-house machining with on-demand relief and infinite, all-in-one manufacturing capacity. Roberson Machine Company is your single-source manufacturer.

We stock top-of-the-line, engineering-grade metal and plastic materials that are suitable for various part applications and industries.

Work with a trusted U.S.-based manufacturer and eliminate the risk of dealing with foreign transactions and shipping. You can also call us at any time at 573-646-3996 or contact us online and we’ll help with any questions you may have regarding ordering parts, design, or material recommendations.

Reach Out to a Leading Provider of CNC Services | Roberson Machine Company

If you’ve looked for reliable CNC services but just can’t find the quality, pricing, or timing that best suits your project, try Roberson Machine Company. Our customers partner with us, and they keep coming back. Our well-equipped machine shop includes numerous CNC turning and milling machines, along with various other top-of-the-line machines, as well as the finest machinists in our industry. We are able to deliver the projects and provide the CNC services other companies simply can’t.

Let us get started on your next CNC services project. Call us today at 573-646-3996 or contact us online.