3D Printing Services

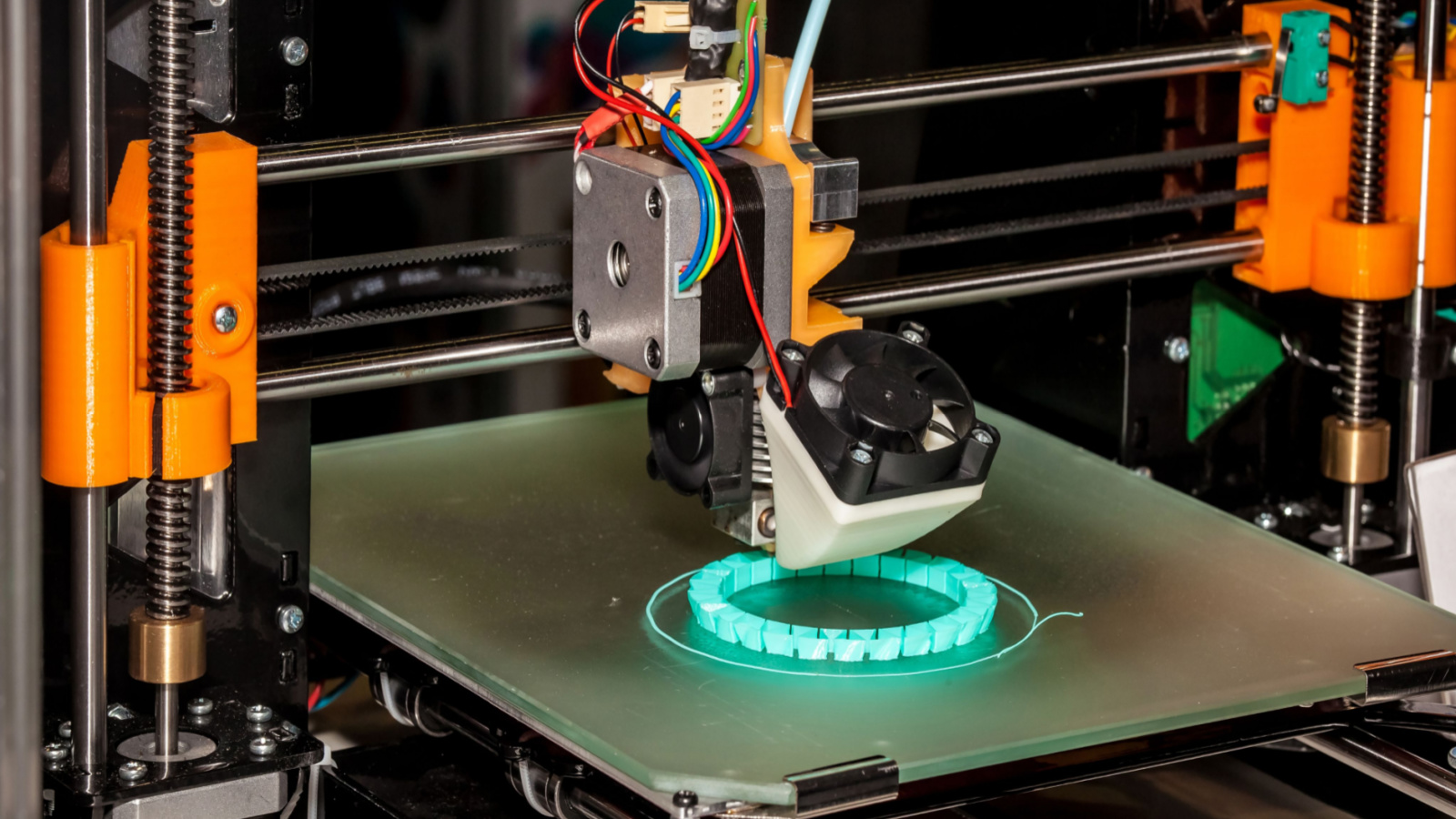

3D Printing Services. 3D printing has quickly become a common way to manufacture everything from plastic trinkets to human kidneys to advanced automotive and aerospace components. In 2022, Roberson Machine Company added new 3D printing capabilities and laser engraving services to our lineup. We are truly amazed at the limitless manufacturing possibilities at our fingertips and the ability to enhance our functionality as a leading single-source manufacturer. Call us today at 573-646-3996 or contact us online to learn more about the endless applications of 3D printing.

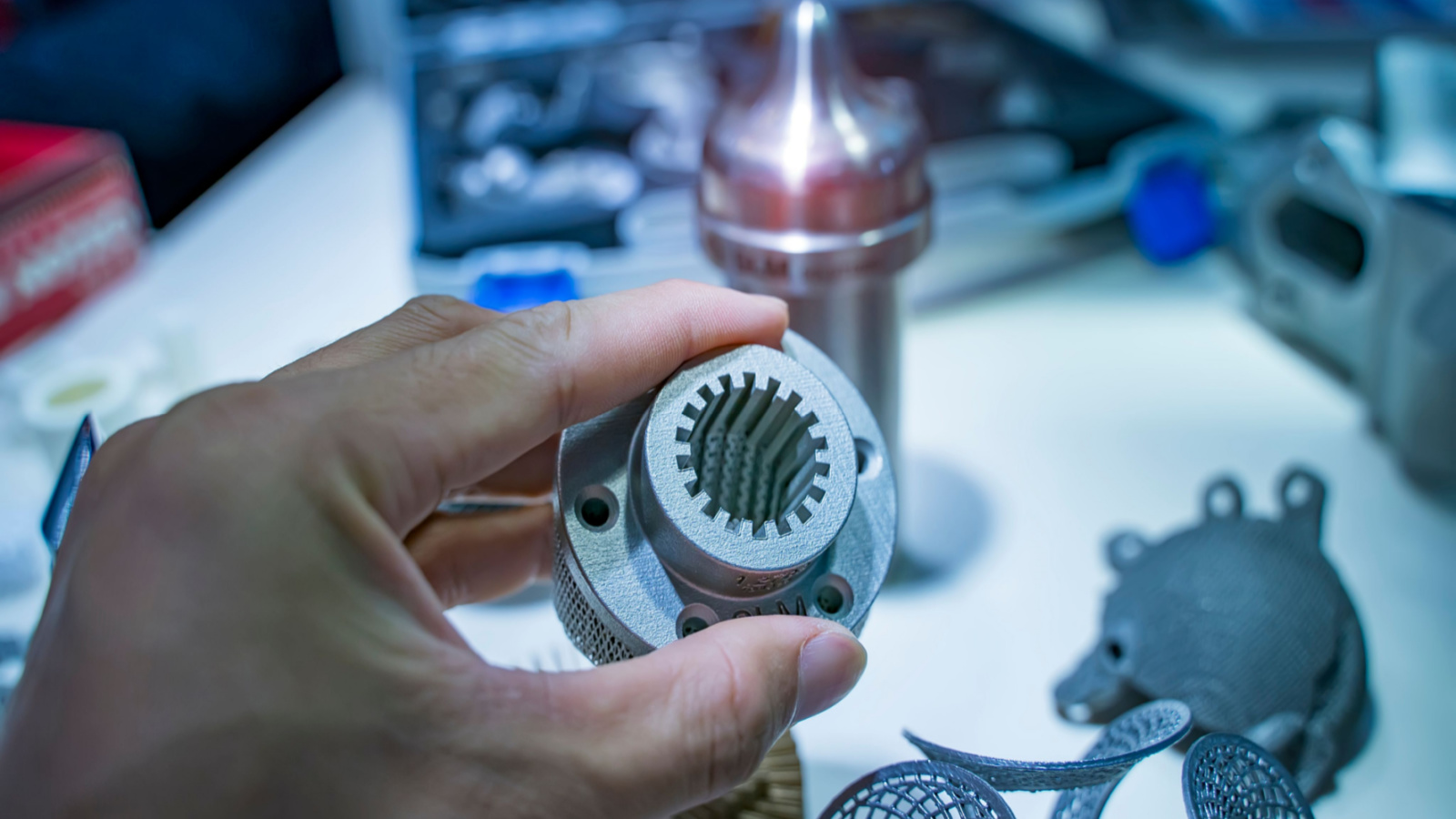

3D printing technology delivers unprecedented manufacturing freedom, creating new production possibilities across the industrial landscape. Roberson Machine Company creates 3D printed parts quickly and efficiently, achieving complex geometries and surface detail in a variety of industry-grade plastics and metals, and customizes your parts for their end-use with a variety of value added, finishing, and post-processing options.

Roberson Machine Company delivers industry-leading 3D printing services. Whether you need prototypes or production parts, we can make them for you on demand in as fast as one day. We are your one-stop shop for accurate, precise, custom 3D printed parts at an affordable price. Feel free to upload your design file in STL or CAD formats to get an online quote and lead time within seconds.

How Does 3D Printing Work?

Everything starts with a 3D model. Most of our industry partners have created designs prior to getting a quote, but our crew is more than happy to work with you from the ground up if needed. We also have a large 3D library. The 3D model is converted into machine language, known as G-code, through a process called slicing, and is ready to print. 3D printing is done layer by layer, sometimes numbering in the hundred-thousands.

Where 3D printing was once only suitable for prototyping and small, one-off manufacturing runs, it is now rapidly transforming into a production technology. According to research from Acumen Research and Consulting, the global 3D printing services market is expected to reach $41 billion by 2026. 3D printing technology will likely transform almost every trade and change the way we live, work, and play in the future.

What Industries Use 3D Printing Services?

3D printing services encompass many forms of technologies and materials, and are being used in every industry. The following are just a few examples:

Car manufacturers have been using 3D printing technology for a long time, from printing spare parts to tools and fixtures. It has also enabled on-demand manufacturing, leading to lower inventory and shortening design and production cycles. Car enthusiasts are using 3D printing to restore old cars, including these Australian engineers who printed parts to bring a 103-year-old Delage Type-S back to life.

The aerospace and aviation industry uses 3D printing services in many different ways for many different parts and technologies. One example is GE Aviation, which 3D printed 30,000 Cobalt-chrome fuel nozzles for its LEAP aircraft engines. Approximately 20 individual parts that previously had to be welded together were consolidated into one 3D printed component that weighs 25 percent less and is 5 times stronger. The engine is the industry’s best selling due to its high level of efficiency, and GE saves $3 million per aircraft by 3D printing the fuel nozzles.

Over the last decade, more than 100,000 hip replacements have been 3D printed. Also, nearly every hearing aid bought and sold since 2001 has been 3D printed due largely to Rapid Shell Modeling. There have also been huge strides in:

-

-

- Dental: Molds for clear aligners, crowns, dentures, and surgical guides have all been 3D printed.

- Biotech: Biotech firms and academia have studied 3D printing services for possible use in tissue engineering applications where organs and body parts are built using inkjet techniques. Layers of living cells are deposited onto a gel medium and slowly built up to form 3D structures.

- Consumer Goods

-

The 3D printed eyewear market is forecasted to reach $3.4 billion by 2028. 3D printing is particularly suitable for eyeglasses frames because the measurements of an individual are easy and quick to process. 3D printing technology has also advanced enough to provide high-quality, custom ophthalmic lenses. The footwear and jewelry industries are also benefiting from 3D printing services.

What Capabilities Does Your 3D Printing Services Have?

From prototyping to high-volume production runs, our 3D printing service is designed for flexible, scalable, cost-effective manufacturing. We use the latest additive manufacturing technology to build affordable functional parts. Give us a call at 573-646-3996 or contact us.

Our build volume for a single extension includes:

- 19 (length) x 19 (width) x 19.6 (height) centimeters OR

- 7.5 L x 7.5 W x 7.75 H inches

And for a dual extension:

- 15.2 (length) x 19 (width) x 19.6 (height) centimeters OR

- 6 L x 7.5 W x 7.75 H inches

While everything is dependant upon what you need to fulfill your project, the materials we use include:

- N6 Carbon Fiber

- N12 Carbon Fiber

- PLA

- PETG

- ESD-PETG

- CF-PETG

- PC-ABS

- PC-ABS FR

- PC PBT

- Polylite

- ABS

- ABS-R (new)

- ABS EC

- ABS ESD

- ABS Kevlar

- ASA

- UF 316L Stainless Steel

- Nylon

- Polymax PC

- Polymax FR

Why Should I Choose Roberson Machine Company For 3D Printing Services?

Accelerate your product development and production processes with our 3D printing services and technologies. Give us a call today at 573-646-3996 or contact us online to discuss your 3D printing project. Our customers partner with us for the following reasons:

-

- Exceptional 3D Prints

Our new machine is raring to go. We use cutting-edge 3D printing technologies to create the highest quality parts for an array of commercial and industrial applications. We can help you with thorough research, enabling you to choose the best technologies and materials to match your products’ properties and applications.

-

- Industry Leading Expertise

Work with a team of manufacturing experts throughout the 3D printing process to take your project from concept to fulfillment. To realize a product that meets the highest quality standards, it is crucial to develop a prototype. This allows for necessary modifications to be identified and modified early on. This saves both time and money.

-

- Manufacturing Innovation

Innovation powers our manufacturing process. Need help 3D modeling your product? No problem, our team can sketch something up right away and help you get IP protection for your design. Roberson Machine Company has been recognized as one of the country’s leading innovative companies. Going from idea to prototype to production has never been easier or faster.

-

- Central Location

We are ideally situated in a central location — on our own land and in our own facilities — for fast delivery times and access to major markets to move our products with ease. Our recently expanded 3D printing facility and our CNC machines are just a phone call away, at 573-646-3996, from helping you with your current 3D printing project.

For the Best in 3D Printing Services | Roberson Machine Company

Our 3D printing services, combined with our CNC machining, separate us from other manufacturers. We look forward to working with you and showing off our newest 3D printing and laser engraving machines. Whatever your manufacturing or production needs, we want to make it as easy as possible for you to try our 3D printing services, and to keep coming back.

Call us today at 573-646-3996 or contact us.