Machined plastic parts. For over 20 years, Roberson Machine Company has machined plastic parts. We take pride in providing top-quality components, experienced staff, and the utmost commitment to our customers in all industries across the country.

Due to the fact that most plastics are comparable to metals in their cost per weight – yet are significantly less by volume – your company might want to look into substituting machined plastic parts where possible on your next project. Call us right away at 573-646-3996 for suggestions on where that may work, or contact us online for a free quote.

To truly harness the machining potential of plastic, precision and customization are paramount. This is where machined plastic parts at Roberson Machine Company come into play, revolutionizing the manufacturing industry. Machining plastic parts requires meticulous attention to detail and an exacting performance from our equipment. Our efficient manufacturing solutions mean a quick turnaround, streamlining your operations and improving your business.

What Are the Advantages of Machined Plastic Parts From Roberson Machine Company?

Some of the benefits of using plastics are that they’re easily machinable and are ideal for applications that require weight, transparency, corrosion resistance, and less friction. Others include:

- Precision and Accuracy

- Cost-Effectiveness

- Quick Prototype and Production Runs

- Material Versatility

- Acrylic (PMMA)

- Nylon (Polyamide, PA)

- Acetal (Polyoxymethylene, POM)

- Polycarbonate (PC)

- Acrylonitrile Butadiene Styrene (ABS)

- Polyvinyl Chloride (PVC)

CNC machining processes offer unparalleled precision, ensuring each plastic component meets your company’s exact specifications. This level of accuracy is unwavering at Roberson Machine Company, and preeminent in vital industries where even a minor deviation can have significant, lasting implications.

While precision is our hallmark of CNC plastic machining, we also provide cost-efficiency, particularly for complex components. Our ability to manufacture intricate shapes in a single process minimizes the need for additional tooling or assembly steps. Call our plastic machining specialists today at 573-646-3996 or reach out to us online for a free quote for your company’s next project or to learn more about our capabilities.

Modern CNC machining allows for rapid prototyping and production. Our CNC plastic machining process provides a swift transition from your concept stage to a tangible, functioning plastic part.

CNC plastic machining allows us to provide a range of versatile materials optimal for your company’s application, considering factors like strength, durability, and chemical resistance. The manufacturing method supports a wide array of plastic materials, including:

Machining Options For Plastic Parts at Roberson Machine Company

CNC machining involves the controlled removal of material from a workpiece to achieve desired shapes and dimensions. When applied to plastics, this process transforms raw plastic materials into precise, complex parts. We utilize the following in-house modern machining techniques, enabling exceptional precision for your company’s components:

CNC Turning

CNC turning, a machining process that typically involves rotating a workpiece while our lathe’s cutting tool removes material to create a part’s shape. Turning is mainly used to produce precise, cylindrical parts or products.

Extremely accurate, CNC turning can be used to turn out thousands of plastic parts that are each identical. Benefits of CNC turning include flexibility, repeatability, speed, and safety. Contact one of our plastic parts machinists today or call us at 573-646-3996 for a free quote.

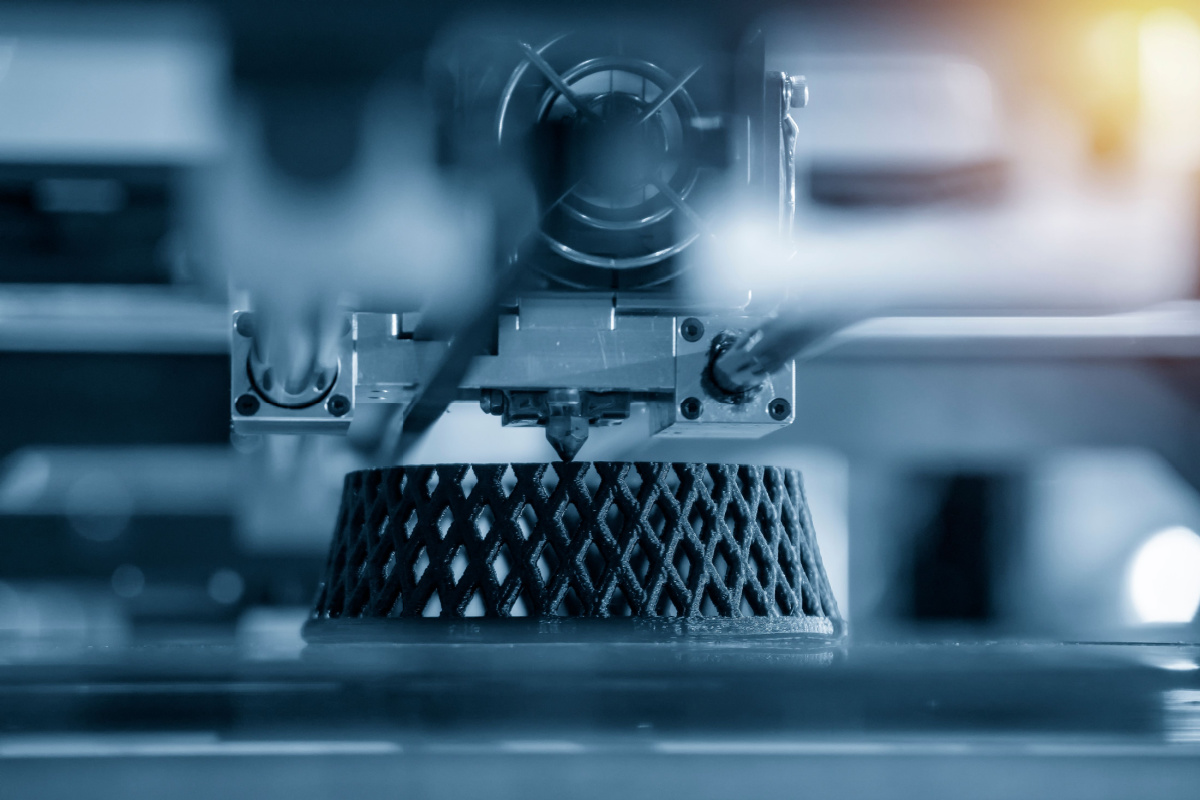

3D Printing

3D printing delivers unprecedented manufacturing services, adding new plastic machining possibilities in our capabilities. We create 3D printed plastic parts quickly and efficiently, achieving intricate geometric shapes and surface details in a variety of industry-grade materials. Roberson Machine Company is your one-stop shop for accurate, precise, custom 3D printed parts at an affordable price.

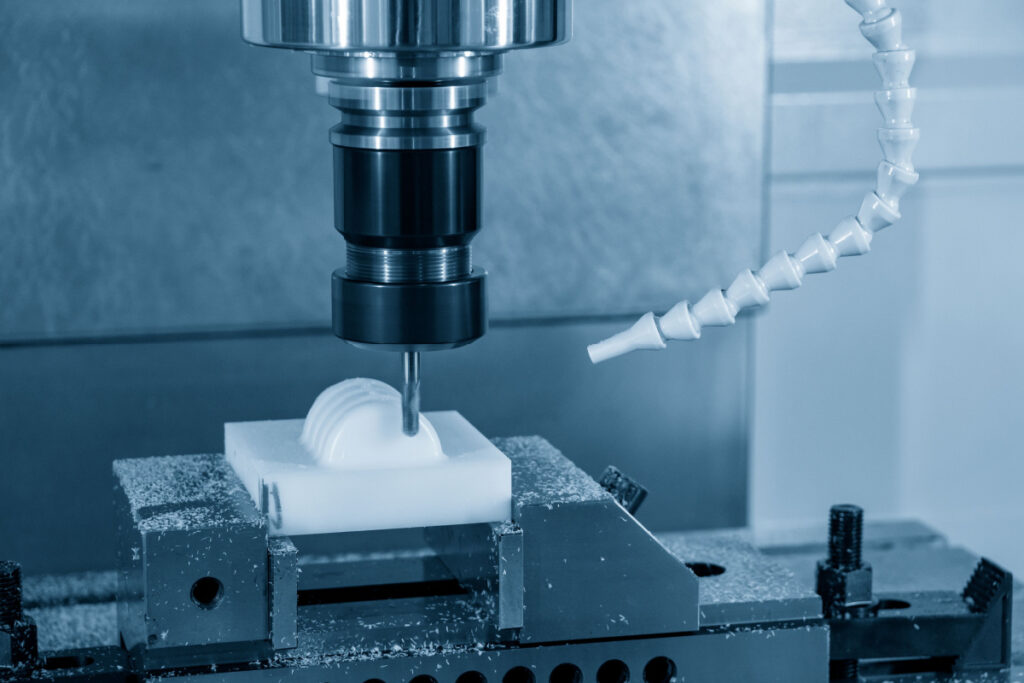

CNC Milling

CNC milling is a machining process that uses a rotating tool or cutter to remove material from a solid piece to get a finished part. We use many different milling methods – including our unparalleled 5 axis and multi axis machining – to achieve plastic parts with complicated geometries with tight tolerances.

Our advanced equipment can machine plastic parts with incredible accuracy, completing demanding jobs effortlessly and on time. By utilizing automated machines with robotic tending technology, along with CAD and CAM software, we can machine plastic parts to meet your needs. Get a free quote on your company’s production run by calling us at 573-646-3996 or reaching out to us online.

What Applications Use Machined Plastic Parts?

The many advantages of machined plastic parts from Roberson Machine Company make them prime choices for a variety of industrial applications. The following are just a few examples:

- Medical and Healthcare Industry: Machined plastic parts are instrumental in creating intricate and biocompatible components used in prosthetic devices, medical instruments, and diagnostic devices. Several specialty plastics are becoming integrated into a wide array of medical devices with antimicrobial additives, to cut down on the likelihood of infections.

- Automotive Industry: From engine components to interior fittings and lighting fixtures, machined plastic parts contribute to vehicle efficiency, safety, and aesthetics.

- Aerospace & Defense Industry: Plastic parts often find their way into aircraft and military vehicle components, enhancing fuel efficiency and reducing overall weight. These components can withstand extreme conditions and temperatures, and play a vital role in aerospace innovations.

Reach Out to the Leader in Machined Plastic Parts | Roberson Machine Company

When accuracy and quality are non-negotiable, Roberson Machine Company is the manufacturer to call. Our machined plastic parts provide precision, versatility, and cost-efficiency, making them indispensable across a spectrum of industries and applications.

Call us today at 573-646-3996 or contact us online for a free quote.