Aluminum CNC Machining

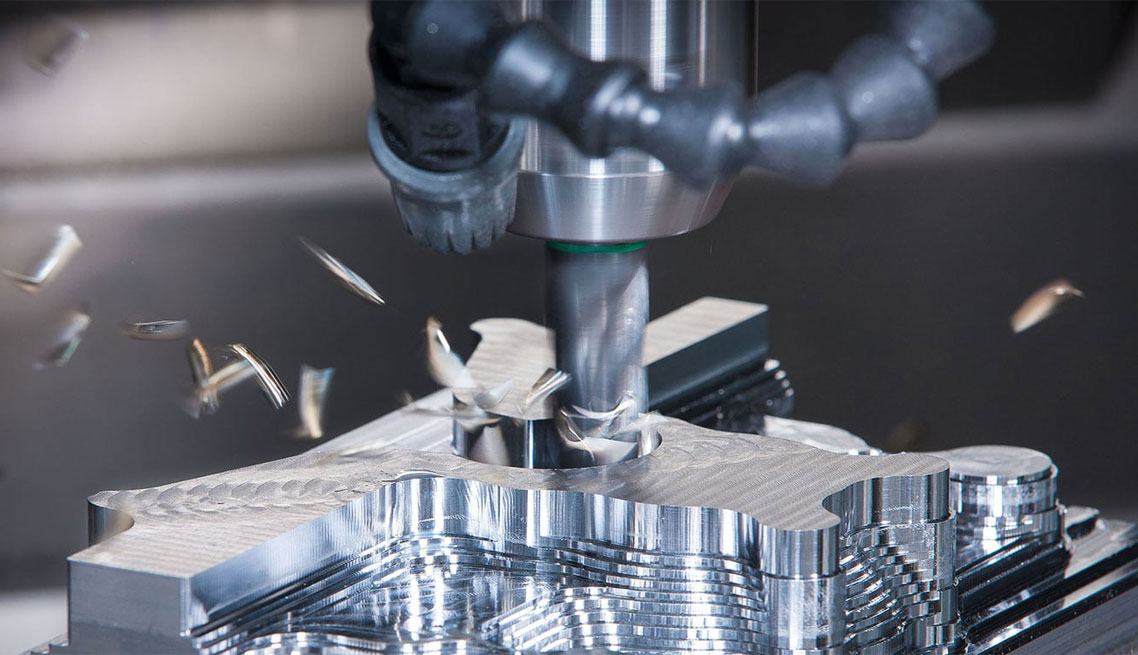

Aluminum CNC Machining. In today’s fast-paced manufacturing landscape, aluminum CNC machining at Roberson Machine Company has emerged as a game-changing technology that offers precision, versatility, and innovation to industries ranging from aerospace and automotive to medical and food and beverage. With its exceptional properties and the power of CNC, aluminum machining has transformed the way products are designed and manufactured.

Call Roberson Machine Company right away at 573-646-3996 or contact us online to get a quote for your next aluminum CNC machining project.

The Best in Aluminum CNC Machining Uses Only the Best Materials

Due to aluminum’s strong, malleable, and extremely versatile nature, we can machine it into the dimensions and specifications you need. Our advanced Aluminum CNC Machining team can work with your company to create incredibly accurate parts.

The types of high-grade aluminum we use for our aluminum CNC machining services include:

Roberson Machine Company has over 20 years of experience in the aluminum CNC machining industry and we are ready to provide your free quote today. Call us now at 573-646-3996 or contact us online.

What Are the Advantages of Utilizing Aluminum CNC Machining?

Aluminum cuts relatively easily and requires less power to machine, due largely to its softness. Aluminum parts machined at Roberson Machine Company retain their primary properties of flexibility and strength, no matter the elements or temperatures.

Some of the other benefits of our aluminum CNC machining services include:

- Precision: CNC machining utilizes computer-controlled systems to execute intricate designs with unparalleled precision. This precision is essential for industries where tight tolerances and exact specifications are absolutely critical.

- Efficiency: Our CNC machines can operate continuously, reducing downtime and ensuring consistent production. This efficiency is particularly valuable for high-volume projects. Need your parts faster than originally planned? We are here to help. Call our experienced team at 573-646-3996 or reach out to us online.

- Versatility: Aluminum is easy to machine, thanks to being dimensionally stable with lower density and tensile strength. Because of this, aluminum CNC machining can be utilized for parts in a wide array of shapes, sizes, and designs. This flexibility is vital for industries that require components with varying complexities.

- Conductivity: Due to its lightweight nature and general affordability, at least compared to other metals like copper or brass, aluminum is frequently used for conductivity. It often gets used for things like battery cables and connectors, particularly in automotive and electric vehicle applications.

- Repeatability: Aluminum CNC machining at Roberson Machine Company ensures uniformity across production runs, no matter the quantity, resulting in consistent, high-quality parts each and every time.

- Recyclability: With environmental concerns at the forefront of what we do at Roberson Machine Company, it’s great to know that an estimated 75 percent of all aluminum produced is still in use. In fact, in industries like automotive and construction, recycling rates for aluminum exceed 90 percent.

What Are Some Possible Future Innovations of Aluminum CNC Machining?

As technology continues to advance, so does the world of CNC machining. At Roberson Machine Company, we strive to stay ahead of the technological curve – keeping up with new and ever-changing methods and industry standards. Call us today at 573-646-3996 or reach out to us online.

The future of aluminum CNC machining holds exciting possibilities, including:

- Automation and AI. The integration of automation, robotics, and artificial intelligence will further improve precision and efficiency in the aluminum CNC machining process.

- 3D Printing Hybridization. The fusion of CNC machining with 3D printing could result in hybrid processes that combine the strengths and efficiencies of both technologies.

- Advanced Materials. The incorporation of new aluminum alloys with enhanced properties will broaden the scope of applications.

- Miniaturization. As demand for smaller, more efficient devices grows, aluminum CNC machining will play a pivotal role in manufacturing intricate, compact components.

The Premier Quality Management Systems Used in Our Aluminum CNC Machining Services

We take our quality management seriously. There is a global certification body that puts Quality Management Systems (QMS) in place, with standards that must be met, before a company can begin serving customers in our aluminum CNC machining sectors. Our internal process adheres to the ISO 9001 and AS9100 certifications. By carefully assessing every stage of our aluminum CNC machining processes, we are constantly looking for ways to become more cost effective and efficient. We also offer several value added services:

- Anodizing

- Heat Treating

- Dimensional Inspection

- Powder Coating

- Bead Blasting

- Passivating

- Engraving/Marking

- Painting

After servicing your aluminum CNC machining needs, you may also need several projects completed before your components are ready for the next stage of your process. Why waste time transporting your aluminum or machining materials between companies, when we can do all the work needed in one location? Our experienced team can manage orders of almost all sizes, delivering promptly and in line with the agreed schedule. We are ideally situated in a central location, on our own land and in our own facility, for fast delivery times and access to major markets.

The Leader in Aluminum CNC Machining | Roberson Machine Company

We offer the highest quality, responsive aluminum CNC machining service that’s tailored to meet your company’s specific needs and timelines. No job is too big or too small. Consistently providing the best aluminum products that meet your most specific criteria, we strive to remain competitively priced for each and every customer.

To find out more, or to get a quote or place an order, call us right away at 573-646-3996 or contact us online.