Aerospace machining. Aerospace machining is a subtractive manufacturing process that involves creating and maintaining aircraft and spacecraft components with CNC cutting tools. Due to the ever-evolving technology of the aerospace industry, where every part must meet stringent standards for quality, safety, and performance, the trusted expertise of Roberson Machine Company is in high regard.

As a leading manufacturer dedicated to elevating the standards of precision machining, and pushing the boundaries of what’s possible, our team has over 20 years of experience in providing cutting-edge solutions for aerospace customers. Call us now at 573-646-3996 or contact us online to get a quote for your next aerospace machining project.

Precision Redefined: Aerospace Machining at Roberson Machine Company

We leverage cutting-edge technologies in our state-of-the-art facilities to stay at the forefront of aerospace machining. Our commitment to innovation ensures that every component meets or exceeds the rigid requirements set by the aerospace industry. Some of these technologies include:

Aerospace components operate in extreme conditions, from high altitudes to rapid accelerations to severe heat and cold. The tolerances of each machined part at Roberson Machine Company are critical to the overall performance and safety of an aircraft or spacecraft. We delve into the minute details of how our aerospace machining processes achieve and surpass these tolerances, ensuring the reliability and longevity of our components.

You Need a Partner You Can Trust: Aerospace Machining by Roberson Machine Company

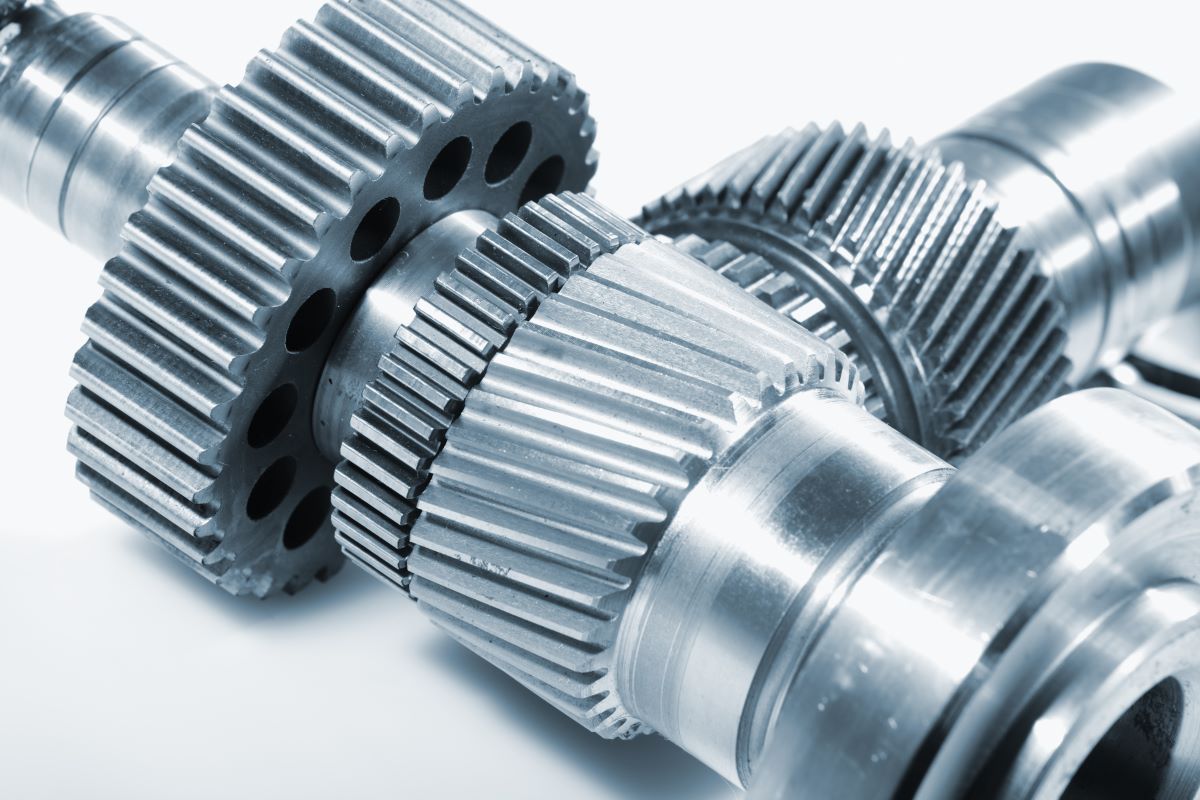

Aerospace machining plays a crucial foundational role in the production of components for aircraft, satellites, missiles, and other defense- and aerospace-related systems. Some of the components manufactured via aerospace machining at Roberson Machine Company could include engine parts, structural elements, landing gear components, turbine blades, and various other critical parts.

Key aspects of aerospace machining are:

- Complex Geometries: Aerospace parts can have intricate and complex shapes, including curves, angles, and fine details. These industry machining processes must be capable of creating complex geometries accurately and on-time. Roberson Machine Company absolutely does – on our own machines, in our own facilities, on our own land. Call us now 573-646-3996 or contact us online to get a free quote.

- Precision Machining: Aerospace components require an exceptionally high level of precision due to the critical nature of their functions. The machining processes involved in our shop are focused on achieving tight tolerances and exact specifications to ensure the reliability and performance of your final parts and products.

- Advanced Materials: Aerospace machining often involves working with advanced materials like high-strength alloys, titanium, composites, high-performance plastics, and other exotic materials. These materials are chosen for their specific properties, including strength-to-weight ratios and resistance to extreme conditions.

- High-Quality Surface Finishes: The surface finish of aerospace components is critical for both functional and aesthetic reasons. Our machining processes are optimized to achieve smooth and defect-free surfaces. We also provide value added services that produce impeccable finishes, including:

- Quality Control and Testing: Quality assurance is absolutely non-negotiable at Roberson Machine Company. Rigorous quality control measures are implemented throughout our machining process. Non-destructive testing, inspections, and quality assurance protocols are vital to ensure that components meet our requirements.

- Tight Tolerances: Components in aerospace applications must adhere to strict tolerances to ensure proper fit and functionality. Our aerospace machining solutions are designed to meet or exceed these tight tolerances.

Given the high-stakes nature of aerospace and defense applications, precision, reliability, and adherence to strict standards are paramount in aerospace machining processes. These are also the precise reasons to choose Roberson Machine Company for all of your company’s machining needs. Give our knowledgeable and experienced team a call right now at 573-646-3996 or reach out to us online for your free quote.

Versatile and Reliable: Choose Roberson Machine Company for Your Aerospace Machining Needs

No matter what your aerospace machining project calls for, whether it’s prototyping or production, we are your one-stop shop for reliable manufacturing capabilities. We are passionate about supporting and retaining our customers. Given our central location and access to major markets, we are able to pass on savings and offer a peace of mind that our competitors cannot.

We take pride in our quality of workmanship and customer service – we aren’t successful unless or until you are. Our loyal team of aerospace machining experts is constantly improving our technological capabilities and processes and making sure that we produce the finest parts for you and your company.

Soar to New Heights With Aerospace Machining at Roberson Machine Company

The role of aerospace machining is becoming increasingly pivotal. Our commitment to precision, innovation, and quality sets Roberson Machine Company apart as a leading manufacturer in the aerospace industry. Whether it’s producing intricate engine components or structural elements that withstand the rigors of flight, our aerospace machining capabilities contribute to the advancement of aviation technology.

Join us on this journey as we continue to redefine precision in the world of aerospace machining. Call us now at 573-646-3996 or contact us online for your company’s free aerospace machining quote.