Aluminum Fabrication

Aluminum Fabrication. Aluminum fabrication has emerged as a pivotal manufacturing process in a variety of industries, from aerospace and automotive to construction and electronics. Due to its strong, yet lightweight and flexible nature, aluminum is machined into many durable and corrosion-resistant components.

Roberson Machine Company has over 20 years of experience in the aluminum fabrication process. Whether it’s forging, machining, drawing, bonding, extrusion, welding, or casting, our entire team is trained in the specific machining techniques required for your company’s needs. We provide all manufacturing services – from initial conception, to prototyping, to the end product.

Call our shop as soon as possible at 573-646-3996 or contact us online to get a quote for your next aluminum fabrication project.

What Are Common Types of Aluminum Used in Fabrication at Roberson Machine Company?

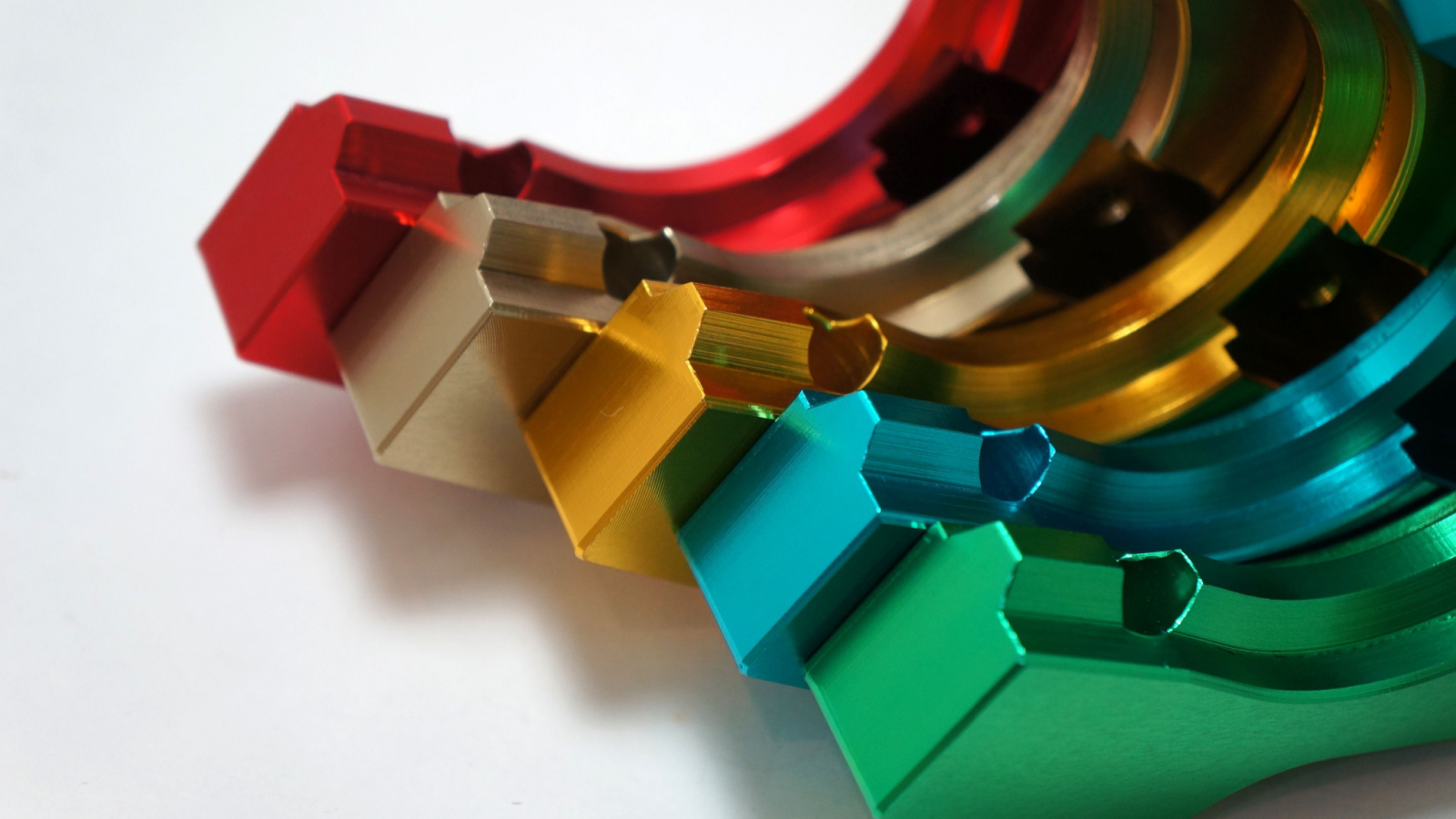

We have the ability to fabricate any type of aluminum and aluminum alloy, tailored to your specific needs. These are some of the popular types of aluminum:

What Are the Best Practices in Aluminum Fabrication?

To ensure optimal results for our customers and to maintain standards of quality, Roberson Machine Company follows a checklist of best practices throughout the fabrication process. These practices include:

- Selecting the Right Aluminum Alloy

- Maintaining Proper Equipment and Tooling

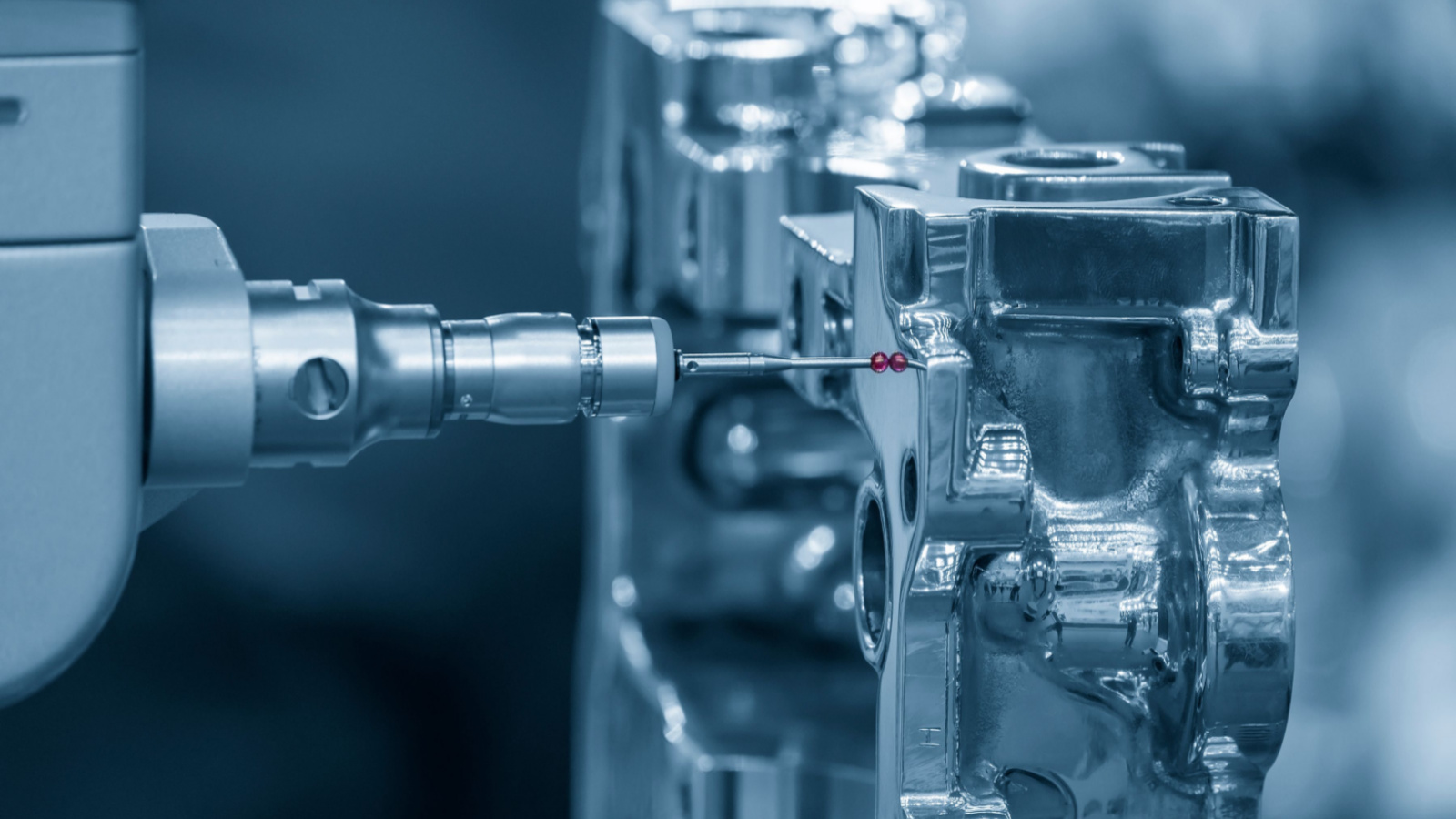

- Ensuring Precision and Accuracy

- Implementing Quality Control Measures

Choosing the appropriate aluminum alloy for a specific fabrication project or technique is crucial. Different alloys have varying properties, such as strength, corrosion resistance, and weldability. Understanding the requirements of the application and selecting the alloy that best meets those requirements will help optimize the fabrication process and your final product. Reach out to our team today with any questions or to get a free quote, or call us at 573-646-3996.

We make sure that our cutting tools, dies, and molds are in pristine condition. We inspect and clean our equipment daily, preventing contamination or damage that may affect quality, speed, or accuracy.

Our aluminum fabrication process frequently involves tight tolerances and intricate designs. Precision machining is vital to achieve the desired fit, form, and function of your fabricated components. We utilize calipers and micrometers throughout the process to ensure accurate dimensions.

Just like our machining and manufacturing solutions, maintaining detailed documentation and records throughout our fabrication process is essential for quality assurance. We take our quality control standards seriously. We take pride in ensuring our aluminum fabricated products and parts are of the highest quality.

Following proper technique, by adhering to our proprietary checklist, and maintaining high standards throughout our fabrication process leads to our continued production of reliable, durable, and high-performance aluminum components. Give us a call right away to get started on your aluminum fabrication at 573-646-3996 or contact us online.

What Are the Benefits of Aluminum Fabrication at Roberson Machine Company?

At Roberson Machine Company, we put quality first. We deliver complex, precise aluminum fabricated components faster than our competitors because of our experienced team of machinists. The following factors make aluminum fabrication an excellent choice for your company’s parts and products:

Aluminum is Lightweight and Durable

Aluminum weighs approximately one-third of the weight of steel, iron, copper, and brass, so it is more malleable and less costly to manufacture. Its strength-to-weight ratio is almost two times stronger than steel, allowing it to be fabricated efficiently and then withstand the weight and strength of the largest machines in every industry.

Aluminum is Ideal for Extreme Temperatures

The heat transfer abilities of aluminum are among the most valuable benefits. Aluminum has the ability to draw off heat when under extreme temperatures like fire or excessive sunlight, making it work well in extreme conditions. Even at the lowest or highest temperatures, aluminum retains its flexibility, strength, and softness.

Aluminum Resists Corrosion

A layer of oxide naturally accumulates on aluminum surfaces, making it resistant to corrosion. We have the capacity to utilize aluminum fabrication on all your projects. Tools, machines, and other products last longer as they corrode less. Call Roberson Machine Company today at 573-646-3996 or contact us online.

Aluminum Has Great Electrical and Thermal Conductivity

Aluminum has 61 percent of the conductivity of copper, which is commonly used for electrical components. It is also considerably cheaper than copper. With its durability and resistance to corrosion, aluminum becomes a better choice than copper for a wide range of products and parts. It is now widely used in HVAC units, as it can transfer heat for both cooling and heating products.

Aluminum is Affordable, Accessible, and Easily Recyclable

Aluminum is the most abundant and cheapest metal on the planet, and is the third most abundant metal in the Earth’s crust. Aluminum is 100 percent recyclable and during the recycling process, unlike other metals, it retains all of its original properties. Recycling aluminum uses far less energy than creating it and – as long as impurities are kept under control – it gets reused indefinitely. We use recycled material in our shop whenever we can to help reduce our carbon footprint.

Reach Out a Leader in Aluminum Fabrication | Roberson Machine Company

Roberson Machine Company provides the best in quality, pricing, and timing in aluminum fabrication for your company’s project. Our industry-leading customers partner with us, and they keep coming back. Our well-equipped shop is centrally located for fast delivery times and access to major markets.

Give us a call today to partner with a one-stop shop for aluminum fabrication at 573-646-3996 or reach out to us online.