Precision and consistency are non-negotiable in the medical field. That’s why choosing a reputable Medical Device Contract Manufacturer in Davenport, IA, is essential for staying compliant, efficient, and ready to meet patient needs. Medical providers count on components that are not only highly accurate but also dependable. In many cases, they rely on high volume orders to support single-use medical products that uphold strict hygiene standards. Just as importantly, these orders must be delivered on schedule and within budget. Roberson Machine Company has over 20 years of experience in precision CNC machining, serving the medical industry with reliable, compliant parts. Call us today at 573-646-3996 or contact us online to start your next Davenport, IA, Medical Device Contract Manufacturer project.

Below, we will discuss various aspects of medical device contract machining and manufacturing. This includes:

- What medical contract manufacturers do

- Why CNC machining is important in the medical sector

- Common use-cases for medical contract manufacturing

- Why Roberson is the go-to contractor for medical device manufacturing

Serving the medical sector nationwide, Roberson Machine Company is an experienced contract manufacturer offering a full suite of precision manufacturing services. Whether you need a small production run or a large-scale order, we have the expertise to meet your needs. Our extensive prototyping capabilities also assist businesses in refining their designs and developing future innovations.

Our key services include:

- Precision Machining: Creation of complex medical parts with high precision and tight tolerances, achieving measurements as precise as ±0.0005 inches.

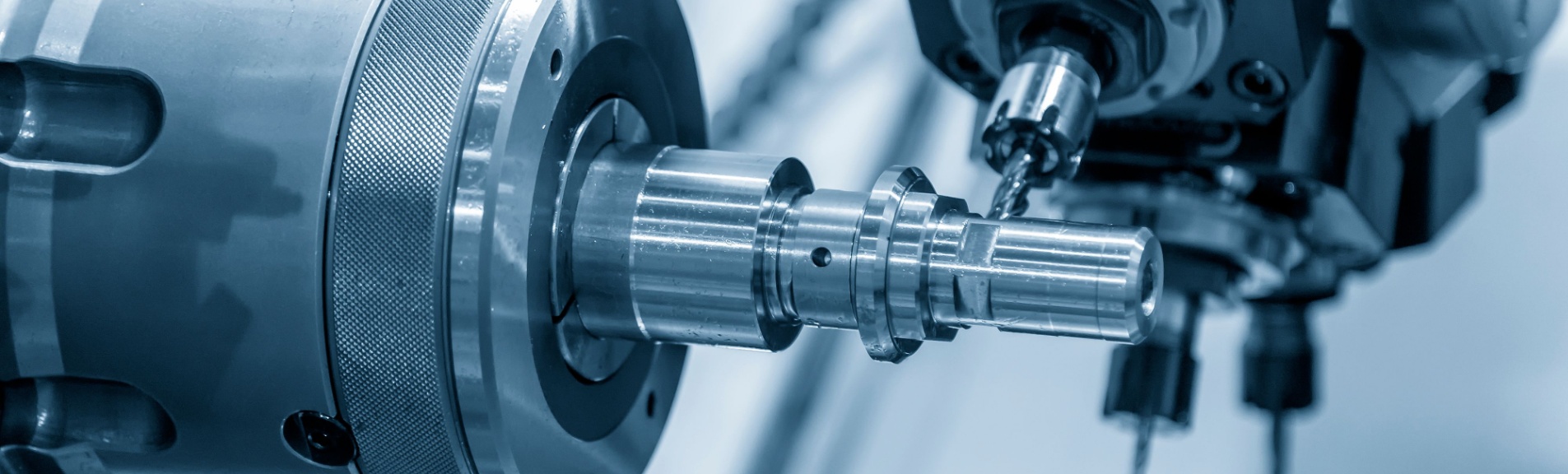

- CNC Milling: Precision multi-axis CNC milling to produce complex, detailed parts with consistent accuracy and reliability.

- CNC Turning: CNC turning for cylindrical and symmetrical components that deliver smooth finishes and precise dimensions.

As a fully company-owned organization, Roberson Machine Company is your trusted partner for medical device contract manufacturing. Questions? Learn more about us and don’t hesitate to ask any questions. We’ve collaborated with companies across multiple industries—see what our clients say. Reach out to our specialists today to discuss your medical device contract manufacturing needs.

What Does a Davenport, IA, Medical Device Contract Manufacturer Do for Healthcare Organizations?

Medical device contract manufacturers are responsible for producing devices and components for healthcare companies and suppliers. At Roberson, we rely on advanced CNC machining technologies to craft precise, dependable, and compliant parts for numerous medical applications. Outsourcing manufacturing enables companies to lower costs, shorten production cycles, and uphold high-quality standards and regulatory compliance.

The medical industry faces unique challenges when it comes to sourcing specialized parts. These challenges include fluctuating demand, high-volume production for disposable components, and substantial start-up costs, which can complicate both part sourcing and prototyping new devices.

What is Contract Manufacturing in the Medical Industry?

Medical device contract manufacturers help businesses solve common production challenges while improving efficiency, reducing costs, and maintaining high-quality standards. Some of the major benefits of contract manufacturing include:

- Lower Overhead: Working with a medical device machining partner cuts production costs, streamlines labor, and eliminates the need for additional workspace.

- Consistency: CNC machining ensures that parts meet the highest standards for functionality and safety, with tight tolerances and quality documentation.

- Responsive Manufacturing: CNC machining allows businesses to scale production on demand, ensuring efficiency at any stage of development.

- Innovation in Manufacturing: Roberson Machine Company stays ahead with continuous CNC technology upgrades for optimal precision and reliability.

- Customization: Advanced CNC technology enables tailored solutions for complex medical components in various shapes, sizes, and materials.

CNC Machining for the Medical Sector

The medical sector in the U.S. relies on highly specialized manufacturing to produce critical components. Many devices are disposable to prevent infections, and parts such as stents, catheters, and surgical screws—sometimes as small as 50 microns—demand extreme precision. Any deviation from exact specifications can pose serious risks.

For the medical industry, CNC machining ensures precision, consistency, and compliance with strict industry standards. Computer-controlled milling and turning processes produce high-quality components with minimal variance. These machined parts play a crucial role in various medical applications, such as:

- Precision and Accuracy: CNC machining ensures tight tolerances, meeting the high functional and safety standards required in medical manufacturing.

- Complex Geometries: With CNC machining, we can produce highly detailed, intricate shapes that are ideal for custom implants and surgical tools.

- Material Versatility: CNC machining works with a broad range of materials, including biocompatible metals, plastics, aluminum alloys, stainless steel, PLAs, PETG, and ceramics, enabling versatile medical applications.

- Rapid Prototyping: CNC machining services streamline the prototyping process, providing fast turnaround times and cost-effective solutions to refine and test new designs.

- Cost Efficiency: Partnering with a CNC machining provider eliminates the need for costly equipment and staffing, enabling high-quality production at a fraction of the cost.

- Meeting Stringent FDA Standards: Contract manufacturers provide the expertise and infrastructure needed to comply with FDA medical device regulations, reducing compliance risks.

- Custom Solutions: CNC technology offers the flexibility to produce bespoke medical components, tools, and devices that meet the precise needs of both healthcare professionals and patients.

Common Use-Cases for CNC Medical Device Contract Manufacturing in Davenport, IA

CNC contracting for medical devices is fundamental in creating highly precise and reliable components for the healthcare industry. Given the stringent performance and safety requirements, CNC machining is an ideal solution for parts with tight tolerances, including those at submicron levels. Below are several medical device applications where CNC machining excels:

- Orthotics: CNC machining creates custom foot and ankle supports, including insoles and braces for comfort and functionality for patients.

- Medical Implants: With CNC machining, we produce key implants such as hip, shoulder, and ankle replacements, utilizing biocompatible materials and exacting tolerances for superior safety and performance.

- Complex Internal and Replacement Parts for Medical Machinery: CNC machining is utilized to produce complex components for medical machinery, including ultrasounds, MRI/CT scanners, and diagnostic equipment, ensuring top-tier performance and reliability.

- Surgical Tools: CNC machining manufactures high-precision surgical tools like scalpels, forceps, and scissors, designed to meet strict safety and performance requirements for medical procedures.

- Lighting Equipment for Medical Procedures: CNC machining creates precise lighting solutions used in surgical environments, providing the necessary illumination for complex medical procedures.

- Safety Enclosures and Mounting Hardware: CNC machining ensures the production of durable enclosures and precise mounting hardware, providing secure and safe installations for medical equipment.

- Custom Prosthetics: By combining CNC machining with additive 3D printing, custom prosthetics are made to ensure an exact fit, improving comfort and function for amputees.

- Orthopedic Devices: CNC machining enables the precise production of parts for knee braces, splints, and other orthopedic devices, ensuring proper fit and optimal support.

- Diagnostic Equipment Components: CNC machining is used to fabricate crucial components such as sensors, connectors, and housings for diagnostic devices, ensuring enhanced accuracy and reliable patient testing.

- Implantable Devices: CNC machining enables the production of life-saving devices like pacemakers and defibrillators, ensuring that biocompatible materials and exact tolerances are met for enduring safety and performance.

See how we’ve tackled unique manufacturing challenges by visiting our case studies page, where we highlight our impact across various industries nationwide.

Roberson Machine Company | Your Trusted Davenport, IA, Medical Device Contract Manufacturer

Roberson Machine Company has been a trusted name in medical contract manufacturing for over 20 years. Owning our facility allows us to invest in cutting-edge CNC machining technology, ensuring precision and efficiency. Strategically located for fast delivery, we serve companies nationwide with high-volume production and custom prototypes. Our additional capabilities—including deburring, engraving, and welding—help optimize your medical device manufacturing process.

We offer a number of different machining services, include:

- Aerospace Manufacturing

- Automotive Part Manufacturing

- EDM Machining

- High Volume CNC Machining

- Industrial Automation

- Solar Panel Manufacturers

- Microscope Parts Precision Machining

- Military Manufacturing

- Medical Brace Manufacturing

From concept to production, our dedicated team is equipped to fulfill your medical device machining needs. Contact us at 573-646-3996, complete our online contact form, or request a quote to see how we can help. We’re here to be your Davenport, IA, Medical Device Contract Manufacturer.