Every part produced for the medical field matters. A dependable Medical Device Contract Manufacturer in Colorado ensures you meet strict industry demands without sacrificing speed or quality. Whether it’s a routine part or a custom solution, healthcare providers often turn to high volume production for single-use items that promote hygiene and safety. Timing and cost-effectiveness are critical factors in every order. With a legacy spanning over two decades, Roberson Machine Company is a go-to partner in CNC machining for the medical industry. Connect with us at 573-646-3996 or contact us here to start your Colorado Medical Device Contract Manufacturer project today.

Wondering how medical devices are machined and manufactured with precision? In the following section, we’ll cover:

- What medical contract manufacturers actually do

- Why CNC machining plays a crucial role in the medical world

- Where medical contract manufacturing is most commonly used

- Why Roberson is a top choice for medical device machining

Serving the medical sector nationwide, Roberson Machine Company is an experienced contract manufacturer offering a full suite of precision manufacturing services. Whether you need a small production run or a large-scale order, we have the expertise to meet your needs. Our extensive prototyping capabilities also assist businesses in refining their designs and developing future innovations.

Our key services include:

- Precision Machining: Manufacture of intricate medical components with tight tolerances as small as ±0.0005 inches for optimal performance and quality.

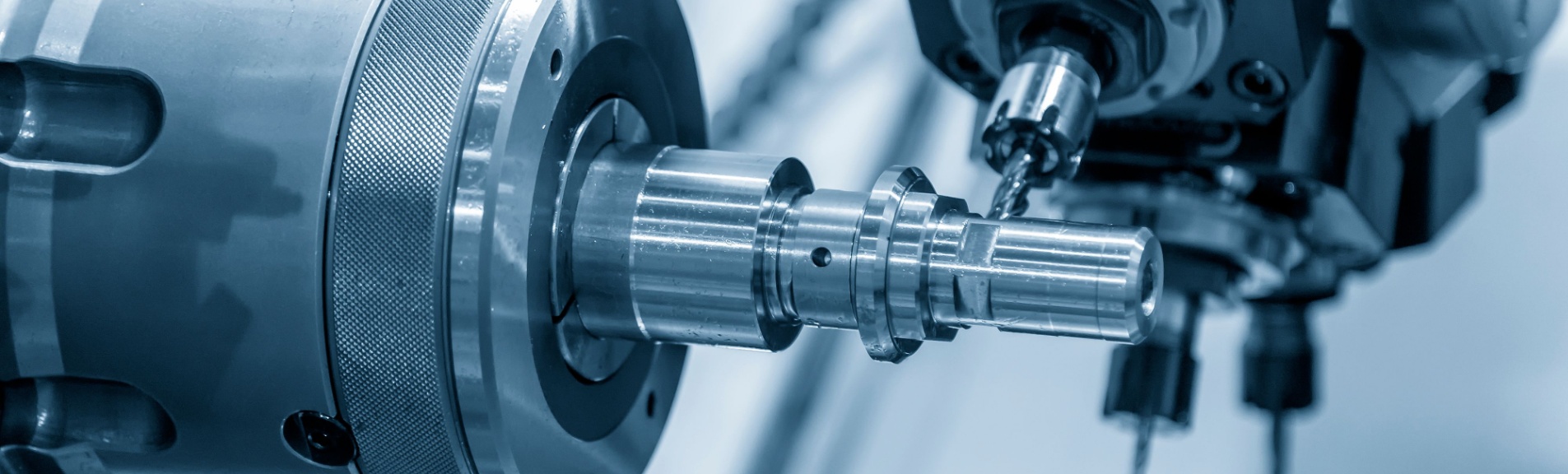

- CNC Milling: Multi-axis CNC milling technology for producing fine, detailed components with accuracy and uniformity in every part.

- CNC Turning: Specialized CNC turning for precision cylindrical components, ensuring smooth finishes and highly accurate measurements.

As a fully company-owned organization, Roberson Machine Company is your trusted partner for medical device contract manufacturing. Questions? Learn more about us and don’t hesitate to ask any questions. We’ve collaborated with companies across multiple industries—see what our clients say. Reach out to our specialists today to discuss your medical device contract manufacturing needs.

What Does a Colorado Medical Device Contract Manufacturer Do for Companies?

A medical device contract manufacturer creates medical devices and components for healthcare providers and suppliers. At Roberson, we use advanced technologies like CNC machining to deliver precise, reliable, and compliant parts for diverse medical applications. Partnering with a contract manufacturer allows companies to cut costs, speed up production, and ensure top-notch quality and regulatory compliance.

The medical industry is driven by the need for specialized parts, each coming with challenges like demand fluctuations, high-volume production of disposable components, and substantial start-up costs. These hurdles can complicate sourcing parts or prototyping new devices.

What is Contract Manufacturing in the Medical Industry?

Collaborating with a reliable medical device contract manufacturer helps businesses address industry-specific challenges while ensuring cost-effective, high-precision production. The main advantages of medical device contract manufacturing include:

- Savings: Beyond cost reduction, partnering with an external medical device machining firm frees up facility space and lowers labor expenses.

- Quality Assurance: CNC machining ensures every component meets exact specifications with rigorous quality control and documentation.

- Efficient Scaling: Increase or decrease production effortlessly—CNC machining supports growth without added equipment or labor costs.

- Advanced Equipment: Roberson Machine Company continuously upgrades its machinery to provide access to the latest CNC technology, improving part quality and precision.

- Flexible Manufacturing: Whether for intricate designs or large-scale production, CNC machining adapts to diverse specifications and material requirements.

CNC Machining for the Medical Sector

In the vast U.S. medical industry, precision is paramount. Many devices are single-use to maintain sterility, while intricate components like stents, catheters, and surgical fasteners can measure as little as 50 microns. Strict tolerances and flawless execution are crucial, as quality issues can directly impact patient outcomes.

CNC machining offers the perfect solution. With computer-controlled milling and turning, parts are produced with high consistency and meet exacting standards. CNC machined parts are used in a variety of medical applications, including:

- Precision and Accuracy: CNC machining offers superior precision, ensuring that all parts meet strict safety and functionality requirements.

- Complex Geometries: CNC machines can create complex, detailed geometries, making them well-suited for custom implants and surgical tools.

- Material Versatility: CNC machining works with a broad range of materials, including biocompatible metals, plastics, aluminum alloys, stainless steel, PLAs, PETG, and ceramics, enabling versatile medical applications.

- Rapid Prototyping: CNC contract manufacturing ensures fast and efficient prototyping, offering a cost-effective way to quickly validate and iterate new designs.

- Cost Efficiency: CNC machining outsourcing minimizes overhead costs associated with equipment, maintenance, and labor, ensuring cost-effective, high-quality production.

- Ensuring FDA Compliance: Medical device contract manufacturers help companies meet FDA regulatory standards, ensuring safe and effective products for the healthcare industry.

- Custom Solutions: CNC machining allows for the creation of personalized parts, tools, and devices designed specifically for the unique requirements of healthcare providers and their patients.

Common Use-Cases for CNC Medical Device Contract Manufacturing in Colorado

CNC contracting for medical devices is fundamental in creating highly precise and reliable components for the healthcare industry. Given the stringent performance and safety requirements, CNC machining is an ideal solution for parts with tight tolerances, including those at submicron levels. Below are several medical device applications where CNC machining excels:

- Orthotics: CNC machining allows for the creation of custom foot and ankle devices, including insoles and braces, that provide optimal comfort and support for patients’ needs.

- Medical Implants: With CNC machining, we produce key implants such as hip, shoulder, and ankle replacements, utilizing biocompatible materials and exacting tolerances for superior safety and performance.

- Complex Internal and Replacement Parts for Medical Machinery: CNC machines craft intricate components for medical equipment such as ultrasounds, MRI/CT scanners, and diagnostic devices built for optimal performance.

- Surgical Tools: CNC machining produces precise tools like scalpels, forceps, and surgical scissors, meeting the high standards required for safe surgeries.

- Lighting Equipment for Medical Procedures: CNC machining produces high-quality lighting equipment for medical use, ensuring reliable illumination during critical procedures in operating rooms.

- Safety Enclosures and Mounting Hardware: CNC machining creates robust enclosures and mounting systems to securely hold medical equipment, ensuring safety and long-term reliability.

- Custom Prosthetics: CNC machining, coupled with additive 3D printing, creates personalized prosthetics that ensure a precise fit and enhance the quality of life for amputees.

- Orthopedic Devices: CNC machining enables the precise production of parts for knee braces, splints, and other orthopedic devices, ensuring proper fit and optimal support.

- Diagnostic Equipment Components: Using CNC machining, components like sensors, connectors, and housings are precisely manufactured for diagnostic devices to guarantee optimal performance and accuracy in patient testing.

- Implantable Devices: Using CNC machining, devices like pacemakers and defibrillators are precisely made with biocompatible materials and exacting tolerances, ensuring their safety and effectiveness over time.

Learn more about how we’ve helped various industries on our case studies page and the different ways we’ve helped businesses throughout the United States.

Roberson Machine Company | Your Trusted Colorado Medical Device Contract Manufacturer

For more than 20 years, Roberson Machine Company has been the go-to partner for medical contract manufacturing. We own our facility, enabling continuous investment in state-of-the-art CNC machining equipment. Our strategic location allows for fast turnaround times and access to key markets. Whether you need mass production or specialized prototypes, we have the expertise. We also offer deburring, engraving, and welding to refine and enhance your medical device components.

Our skilled professionals are ready to partner with you for all your medical device machining projects. Reach out today at 573-646-3996, fill out our online contact form, or request a quote to discuss how we can meet your needs. We’re here to be your Colorado Medical Device Contract Manufacturer.