Wire EDM Lexington, KY

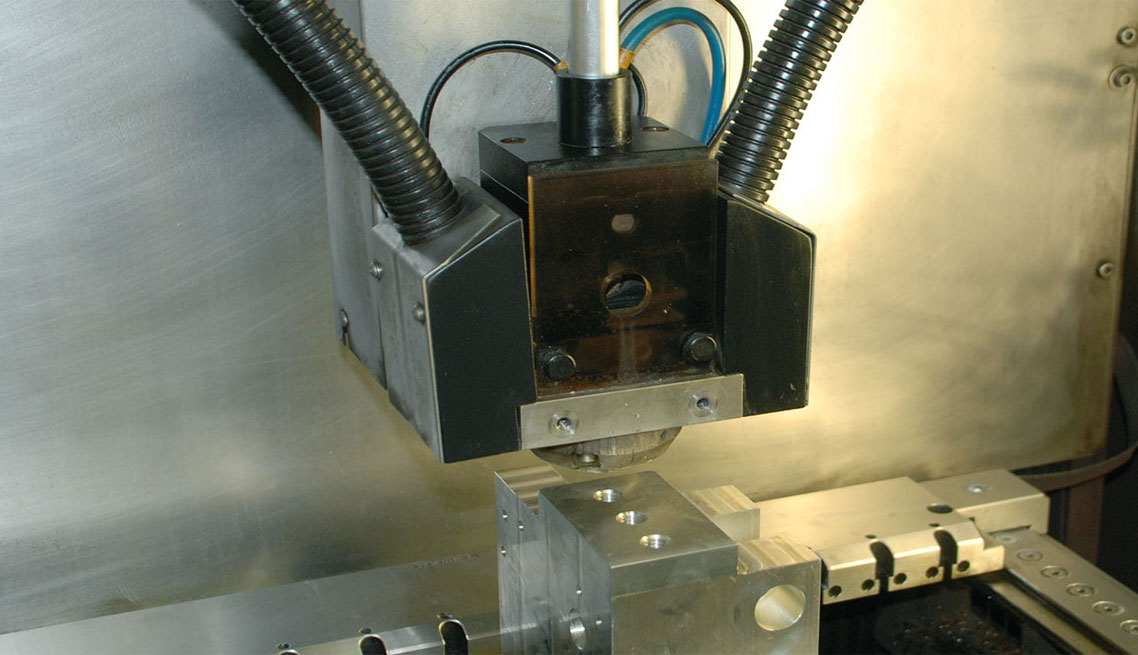

Wire EDM Lexington, KY. In search of a precise machine that supplies more for your project and costs far less? Roberson Machine Company supplies an array of Wire EDM materials and solutions for our customers. Ideal for complex, demanding projects, Wire EDM (Electrical Discharge Machining) is a non-traditional method of removing material (cutting) using thermal energy. Wire EDM does not need mechanical force in the cutting process.

We want to hear about your next Wire EDM project in Lexington, KY! Call us now at 573-646-3996 or reach us here to get your free quote.

Wire EDM Services Save Time and Money in Lexington, KY

One of the major advantages of using Wire EDM is that it eliminates the issue of irregularities or burrs. Wire EDM finishes with an ultra smooth surface that needs no additional processing or smoothing, cutting back on production time and costs. Being able to make components cheaper, faster, and to a higher standard than our competitors pans out to more production with no reduction in quality, enabling us to offer our Wire EDM customers more for less in Lexington, KY.

Roberson Machine Company specializes in manufacturing parts to specific stipulations using our Wire EDM systems which are capable of cutting over 16 inches tall and up to a 45 degree angle for taper.

Advantages of Using Wire EDM in Lexington, KY

- Accurate cuts — tolerances of +/- 0.0003” can be achieved

- More accurate prototype and production runs with shorter lead times

- Material hardness does not affect process

- Cutting complex shapes and thin walled configurations without distortion

- No tooling necessary

- Ability to machine pieces up to 12”

- No-contact, no-force process — making it well suited for delicate, fragile parts

- Does not generate burrs

Wire EDM Specifications and Capabilities in Lexington, KY

- Maximum Angle for Taper: 45°

- Maximum Cutting Height: 16.5”

- Tolerance Maintained to: .0003”

- Wire Diameters: .002” – .010”

- Maximum Weight of Workpiece: 1800 lbs.

- Maximum Angles: +/- 10° at 12” thick workpiece; 30° at 3.25” workpiece; 45° at 1.93” workpiece

- Maximum Travel: X=21.7”, Y=14.6”, Z=12.2”

Along with our Lexington, KY Wire EDM services, Roberson Machine Company provides the following for our Lexington, KY customers:

- CNC Milling Aluminum

- Plastic Parts Manufacturer

- Precision Manufacturing

- Aerospace Machining

- Machined Plastic Parts

- CNC Companies

- Steel Machining

- Aluminum Fabrication

- Machined Parts

- Machine Shop

Wire EDM Machining Useful in a Variety of Industries in Lexington, KY

Wire EDM is an extremely versatile option that is the preferred choice of many industry professionals. We can produce parts to meet your specifications by utilizing EDM systems in differing materials — hardened steels, exotic metals, brass, carbide, aluminum, and graphite. Using Wire EDM machines gives us the capacity to deal with a variety of your production needs from prototype to short, medium or long run production. We regularly provide Wire EDM machining services to the following industries in Lexington, KY:

Our Turnkey Techniques for Wire EDM

When you are looking for Wire EDM solutions in Lexington, KY, turn to Roberson Machine Company, the national manufacturing company specializing in Wire EDM that you can trust. Price is always a consideration for our customers, as it should be, which is why we do whatever we can to use turnkey techniques in our work for Lexington, KY. We are always analyzing our systems, looking for ways to innovate and redesign as a way of giving you the results you seek for less without reducing the quality of the Wire EDM systems and materials in Lexington, KY. We take pride in delivering value added services. Our knowledgeable and skilled specialists can complete these services, giving you the top treatment you need for cost effective, efficient production without having to transport components from one location to another for completion.

Wire EDM Machining Done the Right Way for Lexington, KY | Roberson Machine Company

We have developed a good understanding of what our Lexington, KY customers need. If you are looking for a responsive, dependable Wire EDM company that carries through within the agreed budget and on time, we have the capability to get the job done.

Roberson Machine Company is ideally situated in a central location, on our own land and in our own building, for access to major markets near Lexington, KY and fast delivery times. Our new Wire EDM system and the recent expansion in our national manufacturing company is just a phone call away 573-646-3996 from assisting you with your current project. We utilize our precision machine shop and have been producing top-notch documentation and processes for all of your Wire EDM needs in Lexington, KY, for over 20 years and counting. Call us at 573-646-3996 or contact us here.