Maintain production control with Contract Manufacturing in Albuquerque, NM, built for scheduling discipline, defined processes, and real-world manufacturing environments. Roberson Machine Company supports mid-volume production and scheduled releases using defined processes that reduce internal bottlenecks while keeping production control intact. Contact us for a quote or call 573-646-3996 to discuss how Albuquerque, NM, contract manufacturing fits into your broader production strategy.

Learn more about the topics below:

- What contract manufacturing is—and when it actually makes sense

- How mid-volume production differs from prototyping and mass manufacturing

- How production work is managed across repeat releases

- The machining capabilities used in contract manufacturing programs

- Common use cases and component types produced under contract

- Industries that rely on contract manufacturing to maintain output

- How to start a contract manufacturing project with our team

Roberson Machine Company supports contract manufacturing with the machining capability, process discipline, and production capacity required to maintain long-term output.

Table of Contents

- What Contract Manufacturing Is

- How Production Is Executed

- Precision CNC Machining Capabilities

- Common Use Cases for Albuquerque, NM, Contract Manufacturing

- Industries Served

- Why Companies Use Contract Manufacturing

- Frequently Asked Questions

- Get Contract Manufacturing in Albuquerque, NM

Explore our reviews, recent case studies, blog, and FAQs for insight into how contract manufacturing works in real production environments. For more than 20 years, we’ve helped companies move repeat work out of internal shops and into stable, production-ready workflows.

What Is Contract Manufacturing?

Contract manufacturing is a production partnership where a manufacturer produces parts or assemblies through a defined, repeatable process.

In a contract manufacturing model:

- The customer sets requirements, specifications, and delivery expectations.

- The manufacturing partner executes production within stable, documented workflows.

- Production output is managed to support repeat releases, not just a single run.

This model is well-suited for controlled, mid-sized production work when internal teams need reliable output without expanding equipment, staff, or floor space.

Who Albuquerque, NM, Contract Manufacturing Is For

Contract manufacturing comes into play when internal production staffing, workflow capacity, or equipment availability limits output. It’s typically led by teams responsible for scheduling, release management, and production continuity:

- Operations and plant management responsible for daily production output, staffing balance, and schedule adherence.

- Engineering leadership overseeing production readiness and build repeatability.

- Responsibility for throughput and backlog held by manufacturing leadership.

- Product and project management overseeing release timing and delivery coordination.

- Procurement-led supplier continuity and sourcing decisions.

The goal isn’t to shift responsibility away—it’s to stabilize production while maintaining control over requirements and outcomes.

When Contract Manufacturing Works

Contract manufacturing in Albuquerque, NM, works best when it’s applied to a defined production need—not treated as a generic outsourcing shortcut. Successful programs start with clear intent around why the work belongs in a contract environment.

Contract manufacturing in Albuquerque, NM, works best when it’s applied to a defined production need—not treated as a generic outsourcing shortcut. The difference is intent: clear ownership, defined scope, and a plan for repeat execution.

- Production requirements and timelines aligned before manufacturing begins.

- Production workflows structured to stay consistent across repeated runs.

- Structured communication that aligns expectations, scope, and responsibility.

- Accountability established for both initial runs and repeat releases.

When those conditions are missing, friction isn’t far behind. Unclear prints, moving scope, miscommunication, and unrealistic expectations undermine consistency—even in otherwise capable shops.

When contract manufacturing is the right fit in Albuquerque, NM, it supports mid-sized production work that demands consistency, scheduling discipline, and the ability to scale without expanding internal capacity.

Contract manufacturing is not an arrangement where visibility drops and updates demand repeated follow-up. It isn’t a price-driven race where parts look fine initially and degrade on reorders.

At its best, contract manufacturing keeps ownership clear: requirements remain yours, while your manufacturing partner executes a defined process designed for production—not a single job. Review prototyping versus production, or contact us to discuss fit and timing.

How Contract Manufacturing in Albuquerque, NM, Is Executed

In a contract manufacturing environment, execution is about maintaining control after a part is released to production. The work must repeat cleanly across orders, revisions, and scheduling changes—not just succeed once.

Managing Contract Manufacturing Projects

After a project transitions into contract manufacturing, attention shifts toward consistent repeatability. Setups, machining approaches, inspection requirements, and release details are defined with the expectation that the part will run again—often repeatedly—without reinterpretation.

Production choices are guided by future releases. Machining methods favor stability instead of convenience. Documentation reflects the real build process, with inspection requirements defined early and maintained across runs.

Reducing resets between orders is a key benefit of this approach. Parts avoid constant re-quoting, re-explaining, and requalification when demand fluctuates. Production remains predictable despite changes in volume or timing.

- Setups and machining methods established once and reused.

- Revisions managed without reworking the entire workflow.

- Inspection requirements established prior to production.

If you’re considering contract manufacturing in Albuquerque, NM, for a current production need, contact our team to discuss scope, timelines, and fit.

Core CNC Machining Capabilities Used in Albuquerque, NM, Contract Manufacturing

Successful contract manufacturing depends on machining capabilities that maintain repeatability, scheduling discipline, and consistent output across releases. At Roberson Machine Company, CNC machining is executed within a controlled production process—not as isolated job work.

Our contract manufacturing programs frequently draw from the following CNC capabilities.

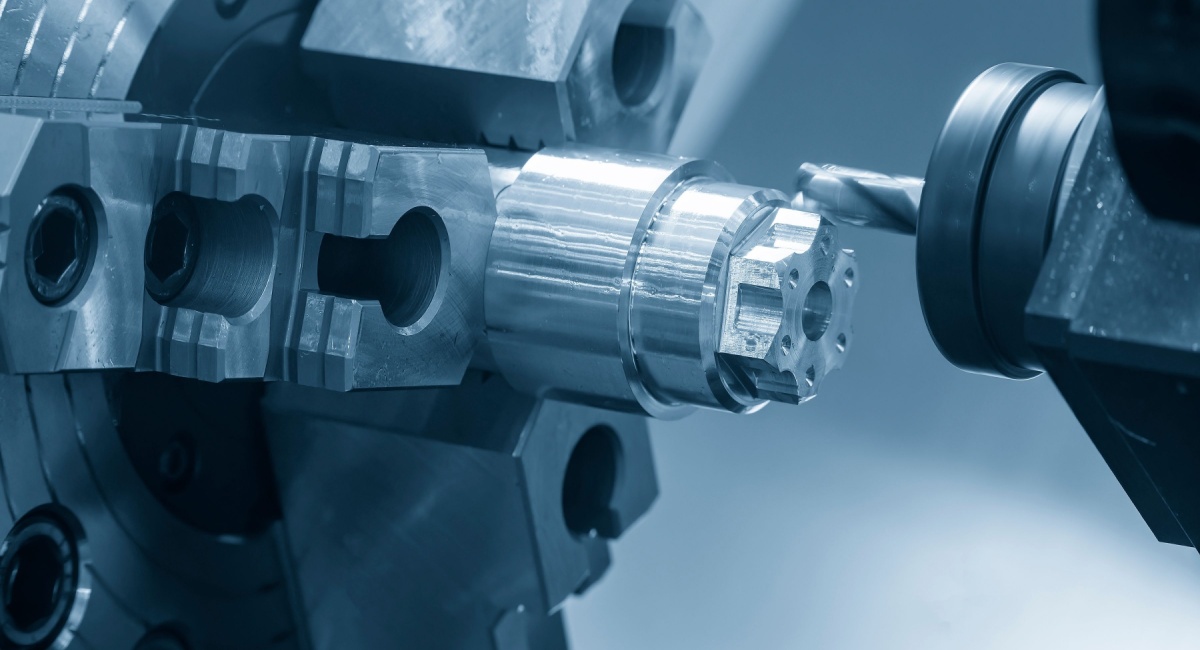

- Precision CNC Machining for controlled tolerances and consistent part quality across runs.

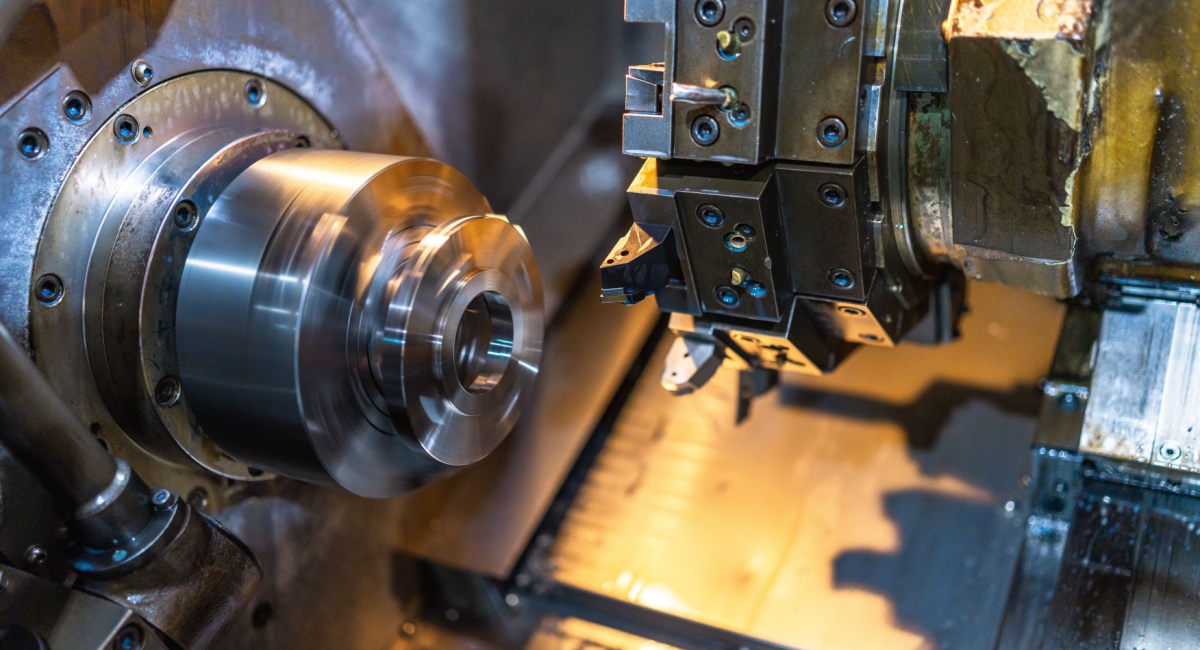

- CNC Turning supporting shafts, housings, bushings, and other rotational components used in contract manufacturing.

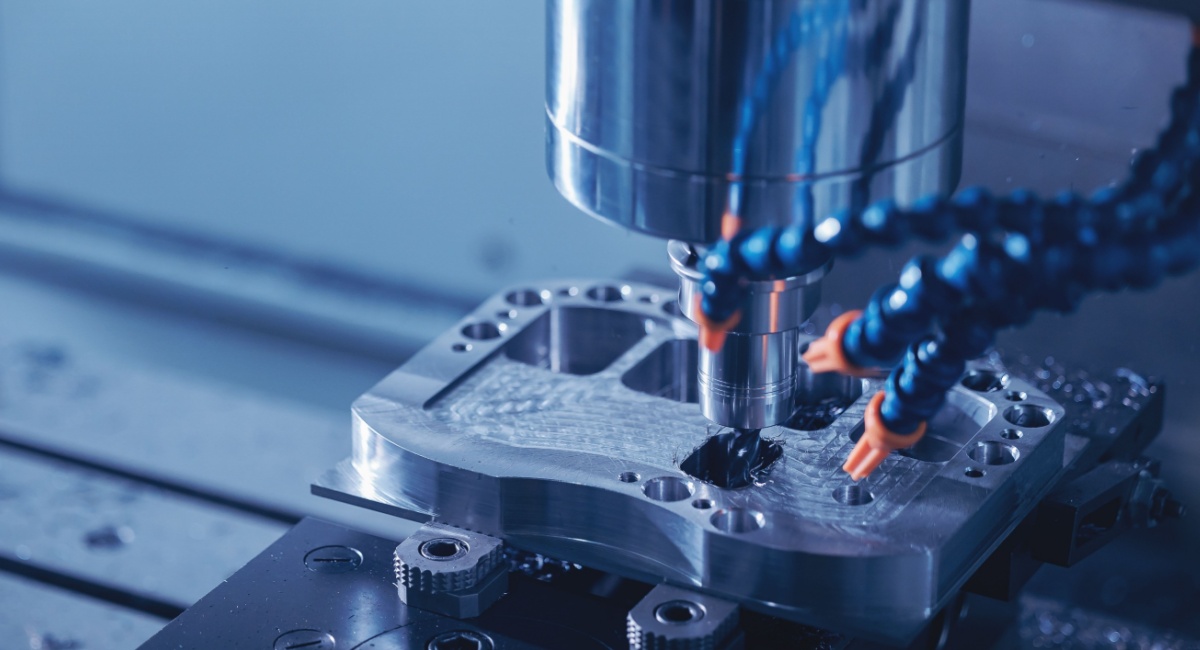

- Multi-Axis CNC Machining when complex feature relationships need to be maintained in one stable setup.

- 5-Axis CNC Machining for complex geometry where reduced setup count improves repeatability.

- Wire EDM for hardened materials and precision features that require non-contact cutting within production.

These capabilities allow contract manufacturing programs to scale mid-sized production runs and repeat releases without retooling strategies or reworking production flow as requirements change.

Use Cases for Contract Manufacturing in Albuquerque, NM

Contract manufacturing is ideal for production work that must repeat predictably, ship on schedule, and maintain dimensional consistency across releases—without adding long-term internal capacity. The examples below reflect common components and scenarios supported under contract.

-

Shafts and pins used for conveyors, actuators, and motion systems—standard components across automation and robotics and packaging equipment.

-

Bushings and sleeves for wear surfaces, alignment, and load control, including components used in automotive assemblies and industrial equipment.

-

Rollers and cylindrical tooling that cycle continuously and require predictable replacement, such as long-duty components similar to our ink roller production work.

-

Valve bodies and fluid-handling components designed to handle pressure, sealing, and repeatability in energy and regulated medical environments.

-

Housings, caps, and mounts used to protect sensors, motors, and instrumentation across automation platforms, medical equipment, and electronics.

-

Turn–mill hybrid parts combining turned geometry with milled flats or slots, typical in specialty assemblies such as end-of-arm tooling.

These parts quietly keep production running. They wear, cycle, seal, align, and transfer motion—and they have to show up on time, built the same way on every release. Contract manufacturing exists to support this kind of work: repeatable components where drift, delay, or variation matters.

Industries That Rely on Albuquerque, NM, Contract Manufacturing

Contract manufacturing is typically used when internal teams face real constraints around capacity, staffing, equipment, or risk. These industries depend on it because production still needs to move even as demand shifts, schedules tighten, or internal resources are committed elsewhere.

Medical Manufacturing

Medical manufacturing places high demands on precision, consistency, and predictable releases. As volumes increase or timelines compress, many organizations with capable internal teams turn to contract manufacturing to stabilize output.

With repeatable mid-sized runs supported by built-in inspection and documentation, contract manufacturing helps medical teams expand production without overextending internal resources. Learn more about our work in medical manufacturing.

Industrial Automation & Robotics

Automation and robotics work evolves at speed. Designs change, volumes move, and parts regularly combine turning and milling within a single assembly.

Contract manufacturing manages this variability through revision-driven releases, mixed part families, and repeat runs that don’t require process resets for each design update. See how we support industrial automation and robotics.

Aerospace & Defense

Aerospace and defense manufacturing places as much emphasis on process control as on geometry. Parts tend to repeat over time instead of running at massive volume, which makes consistency, documentation, and inspection critical.

This work is supported through contract manufacturing that maintains stable workflows and repeatable setups across releases. Explore our experience in aerospace machining and defense manufacturing.

Energy, Oil & Industrial Equipment

Energy and industrial equipment manufacturers work with demanding materials, heavy-duty components, and uneven ordering cycles. Internal shops frequently focus on core assemblies, pushing supporting parts to contract manufacturing partners.

Shafts, housings, valve components, and other parts that face real-world operating conditions are commonly supported through contract manufacturing. Learn more about our work in energy and oil manufacturing.

Packaging & Production Equipment

Packaging and production equipment are built around uptime. Components have to repeat accurately, replace cleanly, and align with existing equipment without variation.

Contract manufacturing delivers a practical solution for supporting repeatable components and replacement parts without locking teams into long-term internal capacity. See how we support packaging and production equipment.

Why Companies Use Contract Manufacturing for Albuquerque, NM, Projects

Companies turn to contract manufacturing when production work starts competing with core priorities instead of supporting them. The value shows up in scheduling stability, cost control under capital pressure, and measurable ROI, not just in unit cost but in fewer resets, less firefighting, and more predictable release cycles.

- Capacity without expansion: Support production demand without investing in new machines, floor space, or long-term staffing.

- More predictable output: Structured processes and repeatable workflows limit variation across releases.

- Lower operational friction: Relieve internal teams of production work so engineering and operations stay focused on core priorities.

- Consistency across repeat runs: Established processes and inspection routines maintain part quality beyond the first release.

- Scalable volume: Adjust production levels without taking on fixed overhead.

- Simplified coordination: Consolidate machining, secondary operations, inspection, and release management into a single workflow.

When set up correctly, contract manufacturing acts as a practical extension of internal production, supporting output with fewer complications.

Contract Manufacturing FAQs

These questions come up as teams evaluate whether contract manufacturing fits their production needs, how to scope the work, and what success looks like beyond the first release.

What’s the difference between contract manufacturing and job shop work?

What volume counts as “mid-volume” for contract manufacturing?

What do you need from us to quote a contract manufacturing project?

Do we have to commit to a long-term contract?

How do revisions get handled once a part is in production?

What should we expect for lead times on repeat releases?

How do we keep visibility once production moves out of our shop?

How do we start a contract manufacturing project with Roberson Machine Company?

Albuquerque, NM, Contract Manufacturing With Roberson Machine Company

Roberson Machine Company supports contract manufacturing programs that depend on scheduling discipline and controlled execution across ongoing production releases. Our role is to stabilize output, manage repeat work, and run defined processes that hold up beyond the initial run.

Contract manufacturing usually includes:

- Established machining processes designed for repeat releases and revision management.

- Capacity planning coordinated with forecasted demand and release schedules.

- Inspection requirements and supporting documentation embedded in production workflows.

- Machining capabilities chosen for long-term stability rather than one-off convenience.

The goal is consistent execution over time, without changing ownership, priorities, or how production decisions are made.

Our core capabilities include:

- CNC Lathe Machining

- Custom CNC Machining for Part Production

- CNC Machine Automation

- Oil and Gas Precision Machining

- Aerospace Manufacturing

- Automotive Part Manufacturing

- EDM Machining

- High Volume CNC Machining

- Industrial Automation

- Solar Panel Manufacturers

Review our machining capabilities, see the industries we support, or contact us online to discuss fit, timelines, and next steps. Call 573-646-3996 to speak directly with our team for more information about Albuquerque, NM, Contract Manufacturing.