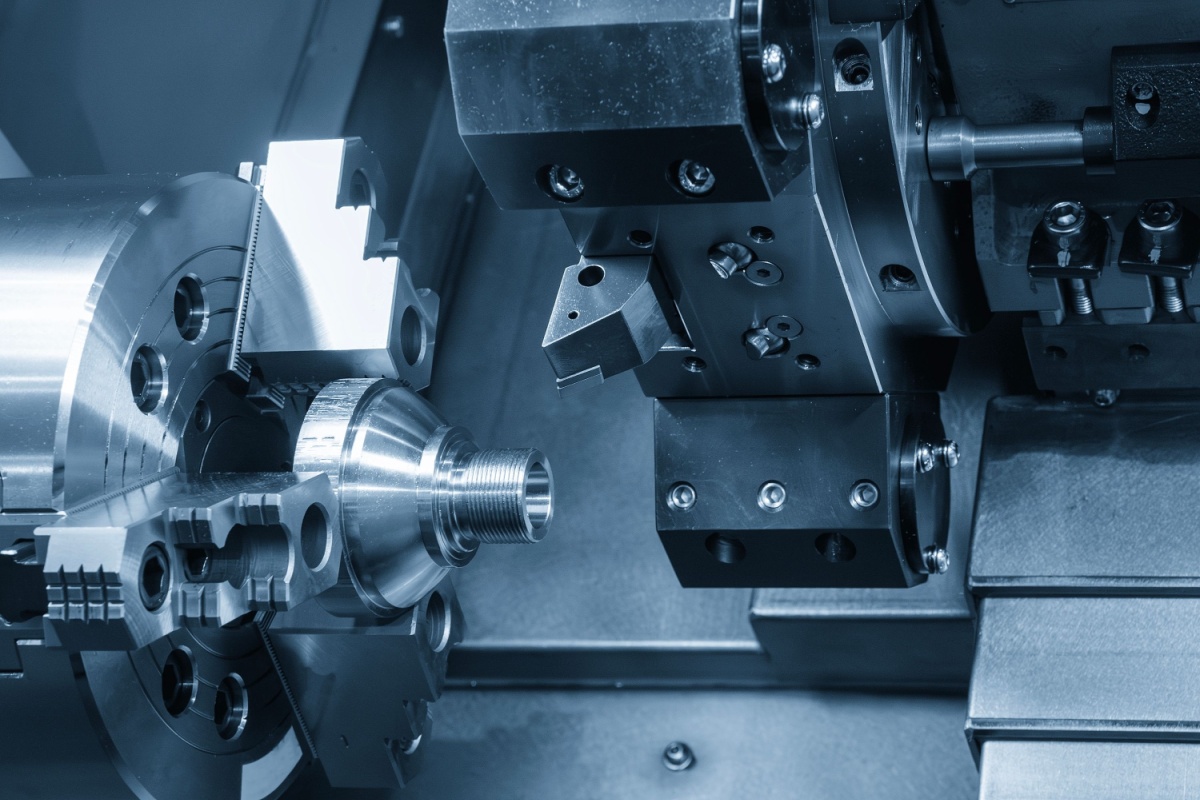

Military Manufacturing Expertise in Syracuse, NY. At Roberson Machine Company, we have over 20 years of experience supporting manufacturers with high-precision custom parts and services. Our advanced CNC machining capabilities enable us to transform intricate concepts into production-ready components that comply with stringent military requirements. From rapid prototyping to large-scale production, we focus on materials and designs that ensure durability, accuracy, and reliability in extreme environments. Whether for aerospace applications, ground systems, or advanced weaponry, our team consistently provides the precision and quality necessary for mission-critical military manufacturing in Syracuse, NY.

Reach out to us at 573-646-3996 or contact us online to discover more about our CNC machining and specialized military manufacturing services. Our team is prepared to help you meet the specific requirements of your project.

CNC Machining for Military Applications in Syracuse, NY

CNC machining — which includes CNC milling — allows you to achieve precise crafting for metal and plastic military components. Durable, corrosion-resistant plastics like polycarbonate, acrylic, and PVC are perfect for applications prioritizing strength-to-weight ratios, making them ideal for rugged cases, drone structures, and portable devices. The adaptability and precision of plastic machining boost efficiency across various military uses.

For applications where resilience is key, CNC machining processes utilize metals like aluminum, steel, and titanium. These metals are essential for military components that endure extreme conditions, such as vehicle armor, weapon housings, and aviation parts. The flexibility of CNC machining in combining metals and plastics creates hybrid components that meet the demanding specifications of military operations.

Applications for Military Manufacturing in Syracuse, NY

Custom prototyping and production for military applications demand the highest standards across various sectors. Roberson Machine Company’s precision machining capabilities provide solutions that meet the exacting needs of military-grade equipment, supporting:

- Aerospace: Utilizing precision CNC milling and 5-axis machining to craft complex, lightweight parts. These advanced methods allow for high-strength designs that fulfill critical safety and performance standards in combat and tactical aviation environments.

- Military Vehicles: Through CNC turning and aluminum machining, we produce resilient vehicle components that endure harsh terrain and demanding field conditions, enhancing the safety and reliability of combat vehicles and transport fleets in military operations.

- Medical Devices: Custom CNC milling for field-grade medical devices used in mobile and battlefield medical units. Each component is crafted to meet regulatory standards, ensuring sterility and reliability in high-stakes, high-mobility environments.

- Industrial Manufacturing: CNC services for high-volume production of uniform, mission-ready parts. Our adherence to quality management standards ensures consistency and quality in every component.

- Energy: Our CNC turning services produce components for portable power and energy solutions, supporting reliable energy systems for field operations and forward-operating bases, even in demanding environments.

Main Services for Syracuse, NY, Military CNC and Product Processes

- Anodizing: This electrochemical treatment strengthens aluminum components by adding an oxide layer, providing improved resistance to corrosion and wear.

- Heat Treating: A thermal process that modifies the structure of metals, resulting in increased strength, enhanced hardness, and improved flexibility for various military and industrial applications.

- Dimensional Inspection: A quality control process that ensures parts meet specified dimensions and tolerances, utilizing precision measurement tools and techniques to guarantee accuracy.

- Powder Coating: A sustainable finishing process that adds a hard, protective coating to metals, combining durability with an attractive appearance without the need for solvents.

- Bead Blasting: A finishing process that uses abrasive beads to clean and texture metal surfaces, preparing them for coatings and enhancing their visual appeal.

- Passivation: A surface treatment that uses chemical agents to form a protective layer on metals, guarding against corrosion and supporting longevity in challenging environments.

- Engraving/Marking: A method for adding permanent identifiers to parts, such as logos or technical data, aiding in traceability and meeting industry compliance requirements.

- Painting: Based on your project, we use different coating processes that provide durability and weather resistance along with aesthetic appeal.

- Black Oxide Coating: This finishing process provides another layer of corrosion resistance and an aesthetically pleasing black finish to parts and machinery.

Innovative solutions from these industries often inspire military advancements. We work to make your ideas a reality by designing, engineering, and producing robust products that meet your strategic needs.

We also offer other Syracuse, NY, metal services, including:

- Aerospace Manufacturing

- Automotive Part Manufacturing

- EDM Machining

- High Volume CNC Machining

- Industrial Automation

- Solar Panel Manufacturers

- Microscope Parts Precision Machining

- Medical Brace Manufacturing

Why Choose Roberson Machine Company for Military CNC Manufacturing and Prototyping in Syracuse, NY?

We work with a number of types of metal to make sure you get the quality product you want. This includes:

- Aluminums: 6061, 7075, 7050

- Stainless Steel: 303, 304, 316, 321, 420SS, 416, 440

- Plastics: Delrin, Nylon, PEEK, HDPE, Glass Filled Nylon

Read about our capabilities in detail on our blog. Roberson’s commitment to quality makes us one of the area’s trusted military manufacturers:

- Versatile Material Selection: From robust metals such as aluminum, titanium, and steel to high-performance plastics, Roberson Machine Company works with materials tailored to meet specific military demands. This versatility enables us to create components that excel in both strength and efficiency.

- Advanced Tolerance Precision: Our CNC machining process achieves ultra-high precision to meet tight tolerances required by military applications, ensuring that parts fit and function flawlessly even in demanding conditions.

- Complex Part Manufacturing: We specialize in creating intricate parts and components using multi-axis CNC machining, which allows for the production of complex geometries needed in cutting-edge military technology.

- End-to-End Manufacturing Support: From the first concept to final production, we offer prototype machining to validate and perfect designs, ensuring seamless transition to large-scale manufacturing.

- Comprehensive Quality Control: Our process includes rigorous dimensional checks, as well as specialized treatments such as passivation, anodizing, and powder coating, ensuring each component’s durability and precision.

Contact Our Syracuse, NY, Military CNC Manufacturing Specialists

At Roberson Machine Company, we’re dedicated to maintaining compliance with military standards that evolve alongside advancements in the industry. Through hands-on training, industry events, and close cooperation with military officials, our team stays informed and prepared to meet regulatory expectations. This dedication supports our mission to deliver components that meet the highest safety and performance standards, reinforcing our credibility and reliability in military applications.

If you have any questions about military manufacturing in Syracuse, NY, CNC milling, or more about our capabilities, give our team a call at 573-646-3996 or contact us online.