Passivation is one of our more popular metal finishing processes at Roberson Machine Company, used to prevent corrosion. It is a chemical treatment for stainless steel and other alloys – aluminum, titanium, and nickel, just to name a few – that enhances the ability of the treated surfaces to protect against rust and other corrosion or contamination.

Call us right now at 573-646-3996 or contact us online for a free quote and to learn more about passivation or any of our other value added services. We have more than 20 years of experience in the industry, providing impeccable service to our clients across the country.

Some of our other value added services include:

- Anodizing

- Bead Blasting

- Powder Coating

- Black Oxide

- Laser Engraving

- Heat Treating

- Painting

- Zinc Coating

- Electroless Nickel

Enhancing Corrosion Resistance: The Power of Passivation at Roberson Machine Company

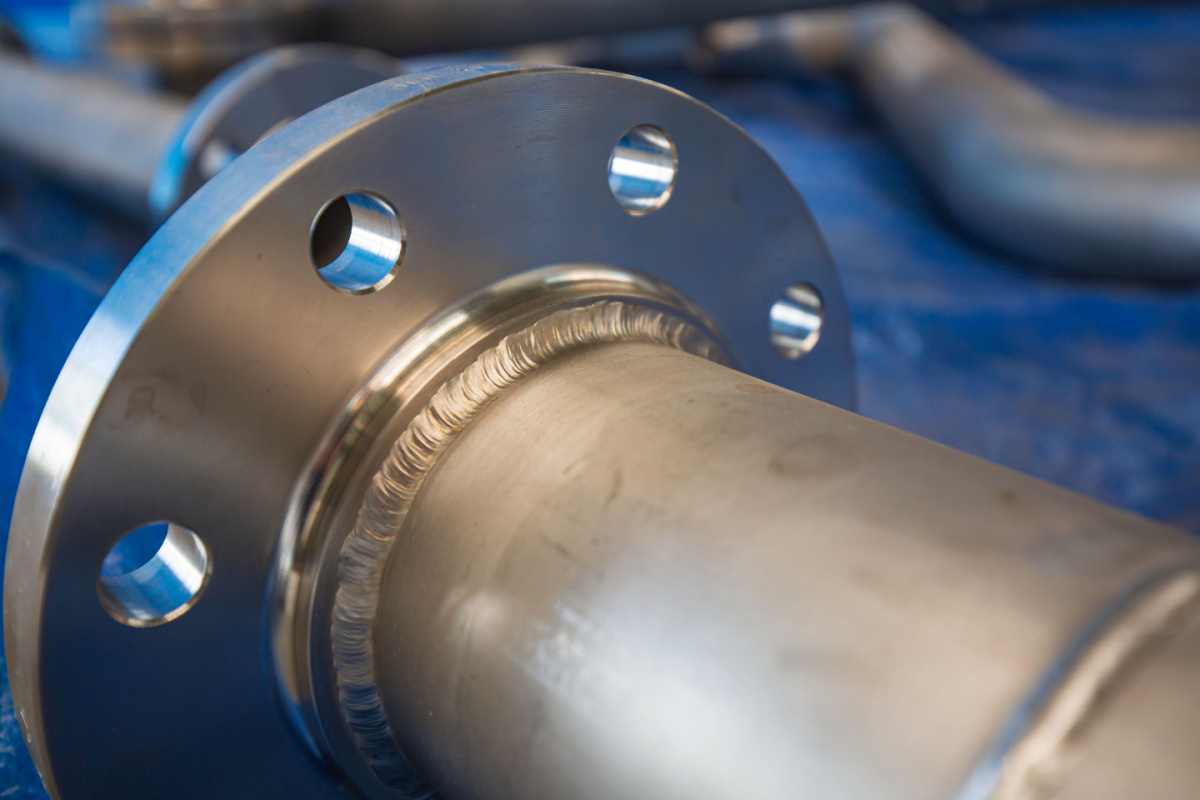

At Roberson Machine Company, where precision, durability, and reliability are nonnegotiable, our passivation services take center stage for finishing metals and alloys. By immersing metal parts in a controlled acid solution – made up of nitric or citric acid – passivation removes surface impurities, contaminants, and iron residues that may have accumulated during the manufacturing process. The end result is a thin, protective oxide layer, or passivation film, that acts as a robust shield against corrosion, even in the most challenging environments.

Passivating with nitric acid is most useful in enhancing the corrosion resistance of freshly machined surfaces. The standard acidic solution is made up of 10-15% by volume of nitric acid (HNO3) in water at up to 150° for 30 minutes for stainless steel. While nitric is the legacy method of passivation, citric acid is a bit safer and more environmentally friendly. The standard solution for passivating is made up of 4-10% by weight of citric acid (C6H8O7) in water at up to 160° for less than 10 minutes.

What is the Passivation Process at Roberson Machine Company?

Stainless steel is an iron-based alloy, made up of iron, nickel, and chromium. The chromium content is what wards off corrosion. Chromium, when exposed to oxygen, forms a thin film of chromium oxide that covers the steel surface and protects the underlying iron from rust. The end goal in the passivation procedure is to augment and optimize the formation of this chromium oxide layer.

The immersion of a metal part in an acid bath dissolves free iron from the surface, while leaving the chromium intact. After exposure to oxygen following the acid bath, the metal forms a chromium oxide layer over the next day or two. To learn more about the process, give us a call at 573-646-3996 or reach out to us online for a free quote.

What Are the Benefits of Passivation at Roberson Machine Company?

In addition to its enhanced corrosion resistance, passivation offers several key advantages:

- Improved Aesthetics: Passivation improves the visual appearance of metal surfaces by removing contaminants, scales, burrs, and discoloration that might have formed during manufacturing. This results in cleaner, more polished parts with an unparalleled ability to stay true to size.

- Extended Component Lifespan: By providing a barrier against corrosion, passivation extends the lifespan of your company’s metal components. This is particularly crucial in industries where reliability and longevity are crucial – like the

aerospace, medical and automotive sectors. - Maintained Part Performance: Passivation does not alter the core properties of the metal, making sure that the part’s mechanical strength, durability, and other functional attributes remain intact.

- Reduced Need For Maintenance: Corroded components require frequent maintenance, repair, or replacement. Not passivated parts from Roberson Machine Company. Our components experience fewer instances of corrosion-related damage, leading to reduced maintenance needs and associated costs.

- Consistency and Precision: Passivation can be precisely controlled to ensure uniform and consistent finishing results across batches of components, whether in large or small production runs, enhancing quality control and repeatability.

- Environmental Sustainability: Just as in everything we do at Roberson Machine Company, passivation contributes to sustainable manufacturing practices by minimizing the need for frequent replacements and reducing waste associated with corroded components. We make absolutely sure any hazardous emissions are self-contained, even in the nitric acid passivation process.

What is Passivation? | Roberson Machine Company

Roberson Machine Company is a manufacturer you and your company can trust. Whether it is CNC turning, CNC milling, wire EDM, or any of other services, our industry-leading clients count on our machine shop to manufacture machined products with exceptional customer care and precise accuracy, all at affordable pricing. Our value added services like passivation are like icing on the cake.

Give us a call today at 573-646-3996 or contact us online for your free passivation quote.