Military Manufacturing Expertise in Glendale, AZ. At Roberson Machine Company, we have over 20 years of experience supporting manufacturers with high-precision custom parts and services. Our advanced CNC machining capabilities enable us to transform intricate concepts into production-ready components that comply with stringent military requirements. From rapid prototyping to large-scale production, we focus on materials and designs that ensure durability, accuracy, and reliability in extreme environments. Whether for aerospace applications, ground systems, or advanced weaponry, our team consistently provides the precision and quality necessary for mission-critical military manufacturing in Glendale, AZ.

Have questions about CNC machining or other military manufacturing services? Give us a call at 573-646-3996 or contact us online to learn how we can meet the unique needs of your project.

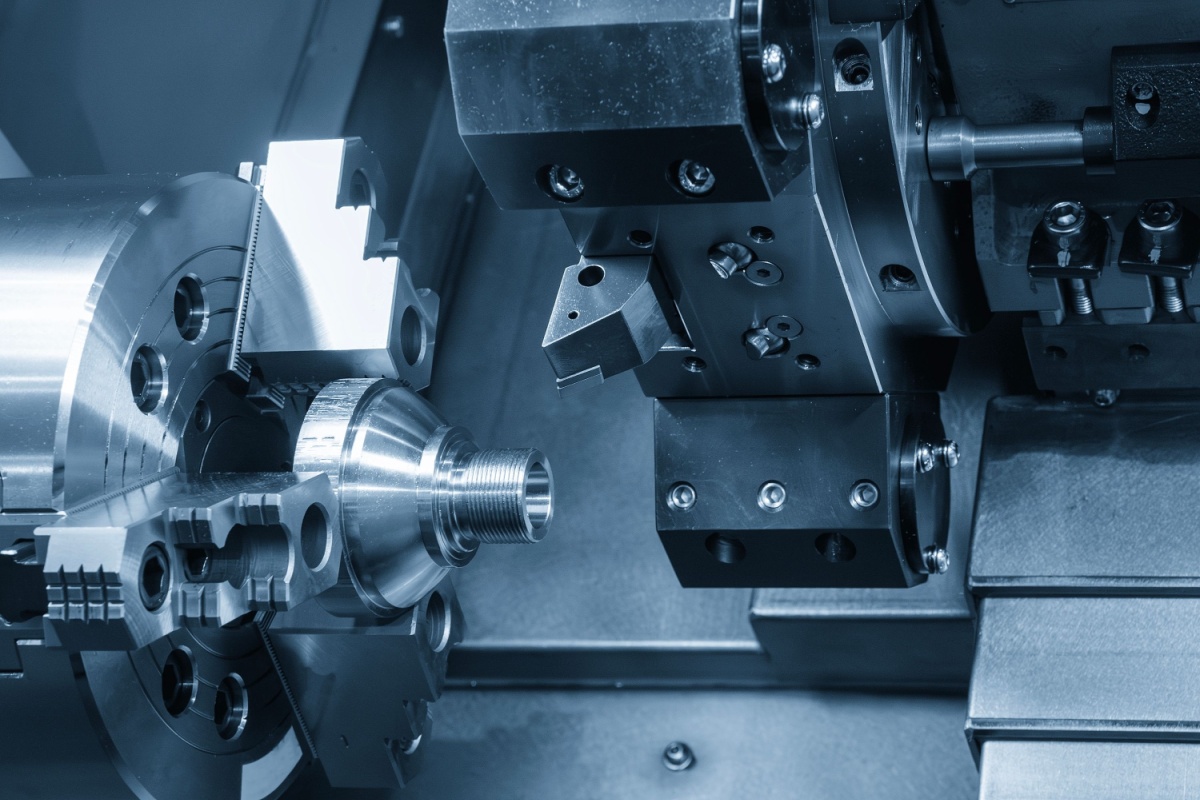

CNC Machining for Military Applications in Glendale, AZ

With CNC machining and milling, we are able to expertly mold metals and plastics into precise military components. Lightweight plastics such as polycarbonate and acrylic offer excellent corrosion resistance and strength-to-weight ratios, ideal for applications like drone frames, protective cases, and field equipment. This precision and flexibility in material choice contribute to mission readiness.

When applications call for tough materials, CNC machining excels with metals like aluminum, steel, and titanium. These metals are ideal for parts requiring maximum strength, such as those in armored vehicles, weapons casings, and aircraft. By integrating metals and plastics, CNC machining produces hybrid components designed to withstand the military sector’s rigorous standards for durability and adaptability.

Applications for Military Manufacturing in Glendale, AZ

Military applications require exceptional standards in custom prototyping and production. Roberson Machine Company’s advanced machining capabilities offer solutions that cater to the strict demands of military-grade equipment, providing support across multiple sectors.

- Aerospace: With precision CNC milling and 5-axis machining, we create complex yet lightweight components for aerospace. These manufacturing methods support high-strength, detail-oriented designs essential for maintaining safety and efficiency in tactical flight environments.

- Military Vehicles: CNC turning and aluminum machining for durable, high-performance vehicle parts that endure extreme terrain and rigorous field testing. These components increase operational reliability and safety for combat vehicles and transport fleets.

- Medical Devices: We specialize in custom CNC milling for medical devices designed for use in mobile and battlefield medical units. Each part is meticulously crafted to comply with regulatory standards, guaranteeing sterility and reliability in demanding, high-mobility scenarios.

- Industrial Manufacturing: We provide CNC services focused on the high-volume production of standardized, mission-ready components. By following quality management standards, we guarantee uniformity and excellence in every part we produce.

- Energy: CNC turning for components in portable power and energy solutions that can lead to reliable energy supply systems for forward-operating bases and field operations under extreme conditions.

Main Services for Glendale, AZ, Military CNC and Product Processes

- Anodizing: An electrochemical process applied to aluminum components to create a durable oxide layer that enhances corrosion resistance and reduces wear.

- Heat Treating: A technique involving controlled heating and cooling to change the internal structure of metals, enhancing characteristics like strength, resilience, and adaptability.

- Dimensional Inspection: This process involves using precision tools to measure and verify that all parts align with required tolerances, ensuring consistent accuracy in production.

- Powder Coating: This environmentally friendly process uses dry powder to create a tough, decorative finish on metal parts, offering both protection and aesthetic appeal.

- Bead Blasting: This surface treatment technique uses fine abrasive materials to remove impurities, creating a uniform texture that improves coating adherence and appearance.

- Passivation: A chemical treatment that enhances the corrosion resistance of stainless steel and other metals by creating a protective oxide layer, improving longevity and performance in various environments.

- Engraving/Marking: A method for adding permanent identifiers to parts, such as logos or technical data, aiding in traceability and meeting industry compliance requirements.

- Painting: A process that applies protective and aesthetic coatings to parts that utilizes a range of paint types to improve durability against environmental factors while enhancing appearance.

- Black Oxide Coating: This process applies a black oxide layer that helps with corrosion resistance and gives parts and machinery an elegant black finish.

Advancements from these industries often translate into impactful military applications. Our mission is to turn your vision into reality by designing, developing, and delivering quality products that align with your objectives.

We also offer other Glendale, AZ, metal services, including:

- Aerospace Manufacturing

- Automotive Part Manufacturing

- EDM Machining

- High Volume CNC Machining

- Industrial Automation

- Solar Panel Manufacturers

- Microscope Parts Precision Machining

- Medical Brace Manufacturing

Why Choose Roberson Machine Company for Military CNC Manufacturing and Prototyping in Glendale, AZ?

We work with a number of types of metal to make sure you get the quality product you want. This includes:

- Aluminums: 6061, 7075, 7050

- Stainless Steel: 303, 304, 316, 321, 420SS, 416, 440

- Plastics: Delrin, Nylon, PEEK, HDPE, Glass Filled Nylon

Read about our capabilities in detail on our blog. Roberson’s commitment to quality makes us one of the area’s trusted military manufacturers:

- Expertise Across Materials: Roberson Machine Company works with a range of materials, including metals like aluminum, titanium, and steel, as well as lightweight, durable plastics. This diversity in materials allows us to create components tailored for specific military uses that bring both strength and efficiency to your project.

- High-Precision Tolerances: Roberson Machine Company’s CNC machining meets the strict tolerances essential for military use, delivering parts that perform seamlessly in demanding environments.

- Specialized Complex Machining: Leveraging multi-axis CNC technology, we create intricate, high-tolerance components that support the evolving needs of modern military innovation.

- End-to-End Manufacturing Support: From the first concept to final production, we offer prototype machining to validate and perfect designs, ensuring seamless transition to large-scale manufacturing.

- Strict Quality Assurance: Through detailed dimensional inspection, along with treatments like passivation, anodizing, and powder coating, we ensure each Roberson Machine Company component meets exacting standards for durability and precision.

Contact Our Glendale, AZ, Military CNC Manufacturing Specialists

Ensuring adherence to military standards is a top priority at Roberson Machine Company. Our team actively engages in continuous training, industry seminars, and workshops to stay aligned with the latest regulations and best practices. By building strong connections with military personnel and regulatory experts, we maintain a thorough understanding of compliance requirements. This dedication to quality and precision ensures that every component we manufacture meets the high safety and performance standards crucial for military applications.

If you’d like to know more about our military manufacturing services in Glendale, AZ, our CNC milling capabilities, or any other specialized offerings, call us at 573-646-3996 or send us a message online.