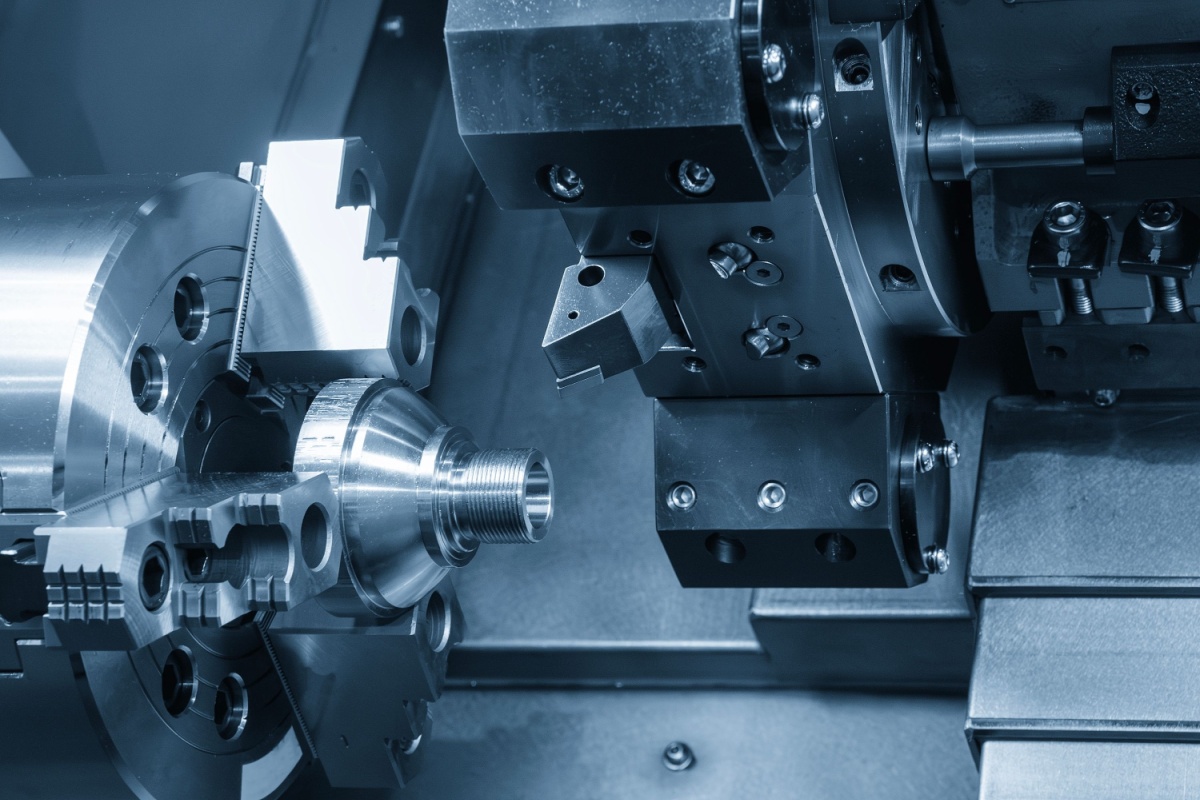

Military Manufacturing Services in Olathe, KS. For more than two decades, Roberson Machine Company has supported manufacturers by delivering high-precision custom parts and services. Our cutting-edge CNC machining technology and diverse capabilities enable us to convert complex designs into components that meet strict military specifications. We offer everything from rapid prototyping to full production runs, utilizing materials and designs focused on durability, accuracy, and reliability under extreme conditions. Whether in aerospace, ground systems, or advanced weaponry, our team ensures the precision and quality required for military manufacturing in Olathe, KS.

Reach out to us at 573-646-3996 or contact us online to discover more about our CNC machining and specialized military manufacturing services. Our team is prepared to help you meet the specific requirements of your project.

CNC Machining for Military Applications in Olathe, KS

CNC machining — which includes CNC milling — allows you to achieve precise crafting for metal and plastic military components. Durable, corrosion-resistant plastics like polycarbonate, acrylic, and PVC are perfect for applications prioritizing strength-to-weight ratios, making them ideal for rugged cases, drone structures, and portable devices. The adaptability and precision of plastic machining boost efficiency across various military uses.

When applications call for tough materials, CNC machining excels with metals like aluminum, steel, and titanium. These metals are ideal for parts requiring maximum strength, such as those in armored vehicles, weapons casings, and aircraft. By integrating metals and plastics, CNC machining produces hybrid components designed to withstand the military sector’s rigorous standards for durability and adaptability.

Applications for Military Manufacturing in Olathe, KS

Meeting the demands of military applications requires the highest standards in custom prototyping and production. At Roberson Machine Company, our precision machining capabilities deliver solutions that meet the rigorous needs of military-grade equipment, supporting various specialized sectors.

- Aerospace: With precision CNC milling and 5-axis machining, we create complex yet lightweight components for aerospace. These manufacturing methods support high-strength, detail-oriented designs essential for maintaining safety and efficiency in tactical flight environments.

- Military Vehicles: By using CNC turning and aluminum machining, we produce tough, high-performance parts designed for extreme conditions. These components are essential for maintaining operational safety and reliability in military vehicles and transport units.

- Medical Devices: Our custom CNC milling services focus on producing field-grade medical devices for mobile and battlefield medical units. Every component is designed to meet strict regulatory standards, ensuring both sterility and reliability in critical, high-stakes environments.

- Industrial Manufacturing: Our CNC machining services cater to high-volume production, ensuring the creation of standardized, mission-ready parts. By complying with quality management standards, we uphold quality and consistency in every component we manufacture.

- Energy: We offer CNC turning services for components used in portable power and energy systems, ensuring reliable energy supplies for forward-operating bases and challenging field operations.

Main Services for Olathe, KS, Military CNC and Product Processes

- Anodizing: A method that applies a robust oxide layer to aluminum, offering heightened resistance against corrosion and wear for increased longevity.

- Heat Treating: A thermal process that modifies the structure of metals, resulting in increased strength, enhanced hardness, and improved flexibility for various military and industrial applications.

- Dimensional Inspection: An essential quality control process using advanced measurement techniques to confirm that each part adheres to specified dimensions and tolerances.

- Powder Coating: A sustainable finishing process that adds a hard, protective coating to metals, combining durability with an attractive appearance without the need for solvents.

- Bead Blasting: A finishing process that uses abrasive beads to clean and texture metal surfaces, preparing them for coatings and enhancing their visual appeal.

- Passivation: A specialized chemical treatment applied to stainless steel and other metals to create a corrosion-resistant layer, optimizing durability for rigorous environments.

- Engraving/Marking: By permanently adding identifiers, logos, and specifications, this process enhances traceability and ensures compliance with technical and regulatory standards.

- Painting: This process involves applying protective and decorative coatings with various metal-friendly paints that enhance the appearance and resistance to corrosion and other environmental factors.

- Black Oxide Coating: This process applies a black oxide layer that helps with corrosion resistance and gives parts and machinery an elegant black finish.

Breakthroughs in these sectors can lead to essential military innovations. Roberson Machine Company is dedicated to helping you transform ideas into tangible, high-quality products that serve your mission.

We also offer other Olathe, KS, metal services, including:

- Oil and Gas Precision Machining

- Aerospace Manufacturing

- Automotive Part Manufacturing

- EDM Machining

- High Volume CNC Machining

- Industrial Automation

- Solar Panel Manufacturers

- Microscope Parts Precision Machining

- Medical Brace Manufacturing

Why Choose Roberson Machine Company for Military CNC Manufacturing and Prototyping in Olathe, KS?

We work with a number of types of metal to make sure you get the quality product you want. This includes:

- Aluminums: 6061, 7075, 7050

- Stainless Steel: 303, 304, 316, 321, 420SS, 416, 440

- Plastics: Delrin, Nylon, PEEK, HDPE, Glass Filled Nylon

Visit our blog to explore our services further. Roberson Machine Company has earned its place among top military manufacturers in the region for several key reasons:

- Wide-Ranging Material Expertise: Roberson Machine Company specializes in materials like aluminum, titanium, steel, and lightweight, durable plastics. This flexibility lets us create military components that achieve the highest standards of strength and efficiency for various applications.

- Precision Tolerance Capabilities: Our CNC machining achieves ultra-precise tolerances critical for military applications, ensuring components fit and function accurately in even the most challenging conditions.

- Precision for Intricate Parts: Using multi-axis CNC machining, we manufacture highly complex parts designed to meet the sophisticated demands of modern military equipment.

- Design Testing and Production: We take projects from prototype to production, using early-stage machining to test and improve designs before ramping up to large-scale manufacturing.

- Enhanced Durability and Quality: Through meticulous dimensional inspection and advanced treatments, including passivation, anodizing, and powder coating, we ensure each part meets stringent durability and precision standards.

Contact Roberson’s Olathe, KS, Military CNC Manufacturing Specialists

At Roberson Machine Company, we’re committed to staying up-to-date with the latest military standards and regulations that shape our field. Our team engages in specialized training, industry conferences, and collaborative workshops, aligning our processes with the most current guidelines and best practices. Through close collaboration with military personnel and regulatory authorities, we maintain a deep understanding of compliance requirements. This dedication strengthens our reputation and ensures that every component we produce meets the rigorous safety and performance standards necessary for military applications.

If you have any questions about military manufacturing in Olathe, KS, CNC milling, or more about our capabilities, give our team a call at 573-646-3996 or contact us online.