Military Manufacturing Expertise in Minneapolis, MN. With over 20 years of experience, Roberson Machine Company is committed to supporting manufacturers with high-precision custom parts and services. Our state-of-the-art CNC machining technology and diverse capabilities enable us to turn complex designs into production-ready components that comply with rigorous military specifications. We offer services from rapid prototyping to full-scale production, ensuring that our materials and designs are tailored for durability, accuracy, and reliability in extreme environments. Whether for aerospace, ground systems, or advanced weaponry, our team consistently delivers the precision and quality needed for mission-critical military manufacturing in Minneapolis, MN.

Reach out to us at 573-646-3996 or contact us online to discover more about our CNC machining and specialized military manufacturing services. Our team is prepared to help you meet the specific requirements of your project.

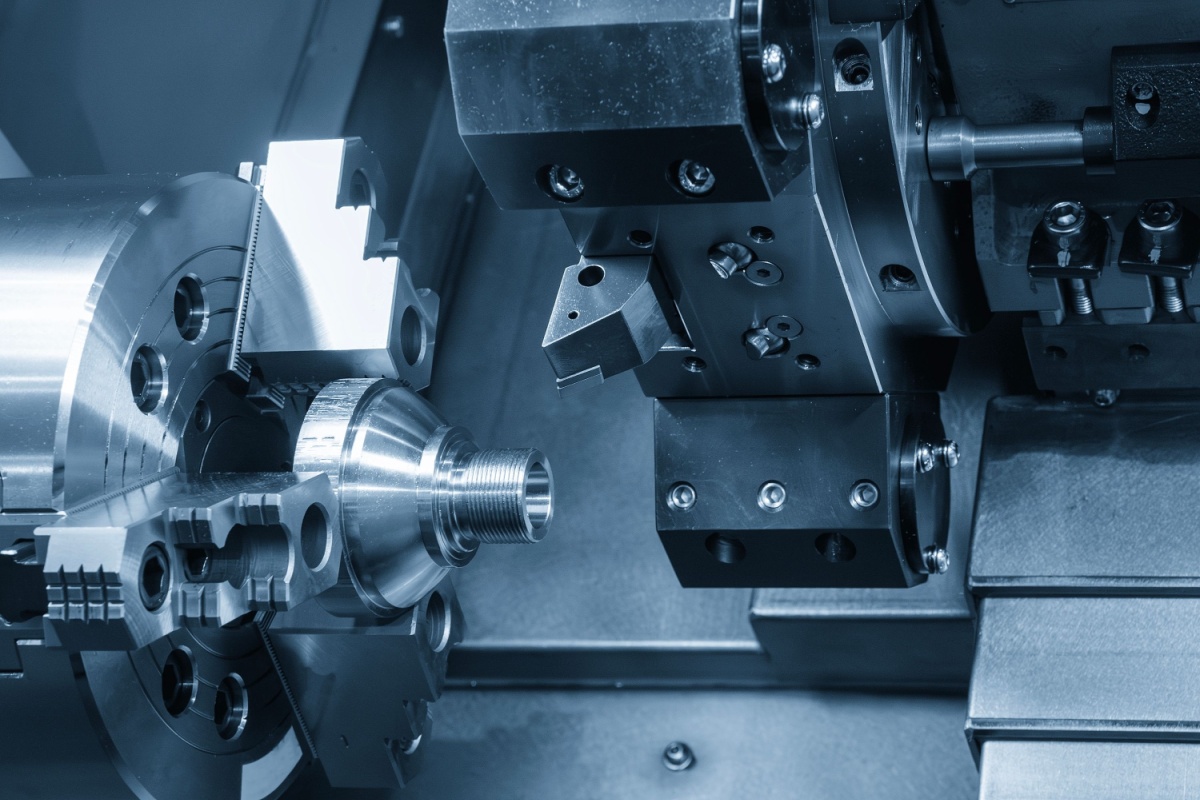

CNC Machining for Military Applications in Minneapolis, MN

CNC machining, which includes CNC milling, offers unmatched versatility in shaping plastics and metals into highly precise military components. Lightweight materials like polycarbonate, acrylic, and PVC provide durability and corrosion resistance, critical for applications requiring optimized strength-to-weight ratios. Examples include components for drone frames, protective casings, and portable gear, all designed to enhance operational efficiency.

For applications that demand highly durable materials, CNC machining can work with metals like aluminum, steel, and titanium. These metals provide the strength and toughness required for rigorous military uses, including armored vehicle parts, weapon housings, and aerospace components. The ability to combine metals with plastics enables CNC machining to create hybrid parts that meet military standards for resilience, accuracy, and versatility across specialized roles.

Applications for Military Manufacturing in Minneapolis, MN

Roberson Machine Company understands the uncompromising standards necessary for military applications, from custom prototyping to production. Our precision machining capabilities meet these stringent requirements, delivering reliable solutions for military-grade equipment across various sectors.

- Aerospace: By employing precision CNC milling and 5-axis machining, we produce intricate, high-strength components that are lightweight and built to withstand the demanding performance and safety standards required for combat and tactical aircraft.

- Military Vehicles: By using CNC turning and aluminum machining, we produce tough, high-performance parts designed for extreme conditions. These components are essential for maintaining operational safety and reliability in military vehicles and transport units.

- Medical Devices: We specialize in custom CNC milling for medical devices designed for use in mobile and battlefield medical units. Each part is meticulously crafted to comply with regulatory standards, guaranteeing sterility and reliability in demanding, high-mobility scenarios.

- Industrial Manufacturing: Offering CNC services tailored for large-scale production, we deliver uniform, mission-ready parts. Our commitment to quality management standards ensures that every component meets stringent quality criteria.

- Energy: Our CNC turning capabilities produce essential components for portable power solutions, facilitating dependable energy systems for forward-operating bases and extreme field conditions.

Main Services for Minneapolis, MN, Military CNC and Product Processes

- Anodizing: An electrochemical process applied to aluminum components to create a durable oxide layer that enhances corrosion resistance and reduces wear.

- Heat Treating: By carefully controlling temperature changes, this process adjusts metal properties to boost durability, hardness, and malleability as required for specific uses.

- Dimensional Inspection: This process involves using precision tools to measure and verify that all parts align with required tolerances, ensuring consistent accuracy in production.

- Powder Coating: This environmentally friendly process uses dry powder to create a tough, decorative finish on metal parts, offering both protection and aesthetic appeal.

- Bead Blasting: Using fine beads, this technique cleans and textures metal surfaces, improving coating durability and providing an attractive, even finish.

- Passivation: This treatment strengthens the natural corrosion resistance of metals, particularly stainless steel, by creating a resilient oxide coating that extends lifespan.

- Engraving/Marking: A process for permanently etching or marking components with identifiers, logos, or specifications, ensuring traceability and compliance with industry standards.

- Painting: The application of durable coatings to metal parts that are available in various types of paint that protect parts and tools from weathering and general wear-and-tear.

- Black Oxide Coating: This finishing technique enhances parts and machinery with improved corrosion resistance and a sleek, attractive finish.

Innovative solutions from these industries often inspire military advancements. We work to make your ideas a reality by designing, engineering, and producing robust products that meet your strategic needs.

We also offer other Minneapolis, MN, metal services, including:

- CNC Lathe Machining

- Custom CNC Machining for Part Production

- CNC Machine Automation

- Oil and Gas Precision Machining

- Aerospace Manufacturing

- Automotive Part Manufacturing

- EDM Machining

- High Volume CNC Machining

- Industrial Automation

- Solar Panel Manufacturers

Why Choose Roberson Machine Company for Military Manufacturing in Minneapolis, MN?

We work with a number of types of metal to make sure you get the quality product you want. This includes:

- Aluminums: 6061, 7075, 7050

- Stainless Steel: 303, 304, 316, 321, 420SS, 416, 440

- Plastics: Delrin, Nylon, PEEK, HDPE, Glass Filled Nylon

You can read more about our services on our blog. Below are a few reasons Roberson has remained one of the top military manufacturing companies in the area:

- Versatile Material Selection: From robust metals such as aluminum, titanium, and steel to high-performance plastics, Roberson Machine Company works with materials tailored to meet specific military demands. This versatility enables us to create components that excel in both strength and efficiency.

- Exceptional Tolerance Accuracy: Our CNC technology ensures precise tolerances, crucial for the reliability of military components, delivering flawless fit and function in rigorous conditions.

- Precision for Intricate Parts: Using multi-axis CNC machining, we manufacture highly complex parts designed to meet the sophisticated demands of modern military equipment.

- Design Testing and Production: We take projects from prototype to production, using early-stage machining to test and improve designs before ramping up to large-scale manufacturing.

- Enhanced Quality Control: With rigorous dimensional inspection, passivation, and surface treatments like anodizing and powder coating, Roberson Machine Company guarantees the durability, precision, and longevity of every component we produce.

Contact Our Minneapolis, MN, Military CNC Manufacturing Specialists

At Roberson Machine Company, we’re committed to staying up-to-date with the latest military standards and regulations that shape our field. Our team engages in specialized training, industry conferences, and collaborative workshops, aligning our processes with the most current guidelines and best practices. Through close collaboration with military personnel and regulatory authorities, we maintain a deep understanding of compliance requirements. This dedication strengthens our reputation and ensures that every component we produce meets the rigorous safety and performance standards necessary for military applications.

To find out more about military manufacturing in Minneapolis, MN, or to discuss our CNC milling capabilities, call 573-646-3996 or get in touch with us online.