Military Manufacturing Solutions in Durham, NC. With over 20 years of experience, Roberson Machine Company specializes in providing manufacturers with high-precision custom parts and services. Our state-of-the-art CNC machining technology and versatile capabilities empower us to convert complex ideas into production-ready components that meet rigorous military specifications. We offer services from rapid prototyping to full-scale production, utilizing materials designed for durability, accuracy, and reliability in extreme conditions. Serving sectors such as aerospace, ground systems, and advanced weaponry, we deliver the precision and quality essential for military manufacturing in Durham, NC.

Don’t hesitate to call us at 573-646-3996 or contact us online to learn more about our CNC machining and other specialized services for military manufacturing. We’re ready to discuss how our expertise can support your project’s unique needs.

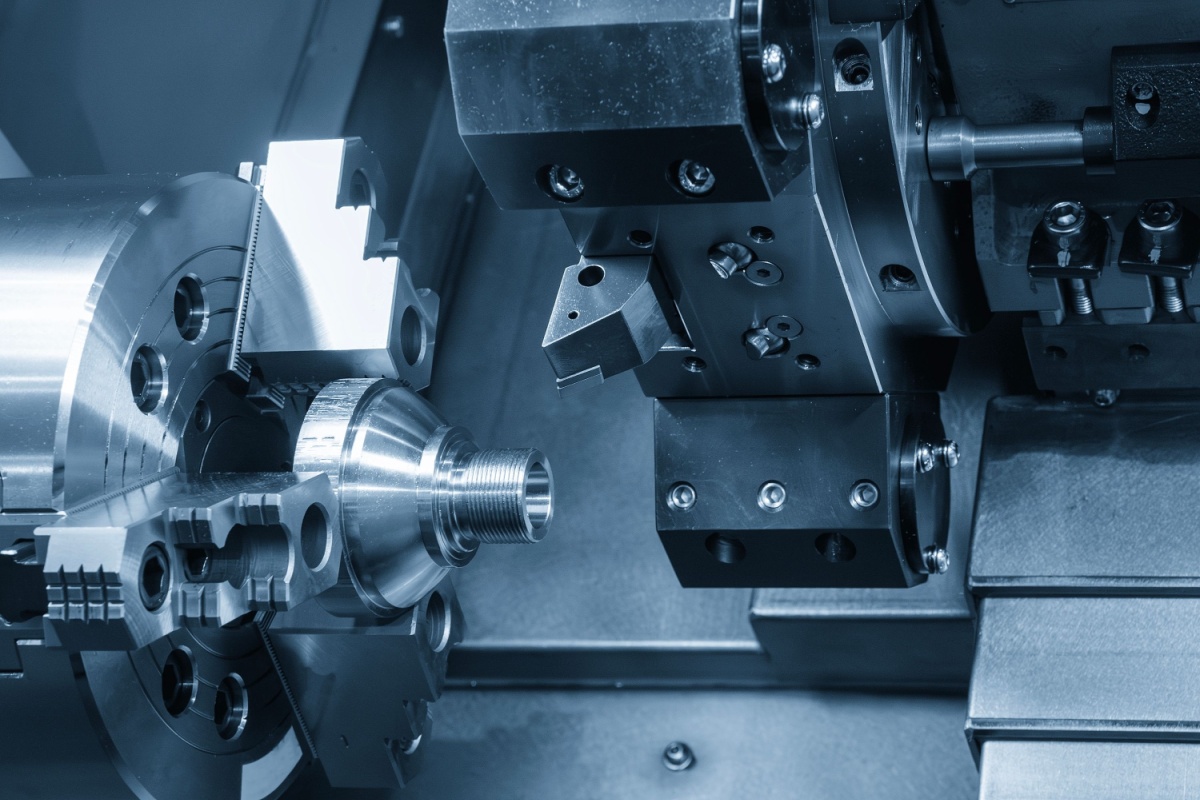

CNC Machining for Military Applications in Durham, NC

CNC milling and CNC machining offers flexibility for crafting both plastics and metals into precisely engineered military components. Lightweight plastics like polycarbonate, acrylic, and PVC are ideal for military applications needing durable, corrosion-resistant, and need to be considered based on their strength-to-weight ratios. This includes items like drone frames, rugged casings, and portable equipment. The customization and ease of machining plastics make them invaluable for enhancing operational efficiency in specific roles.

For military components that require extra strength, CNC machining works effectively with metals such as aluminum, steel, and titanium. These materials deliver the durability needed for demanding applications like armored vehicle frames, weapon enclosures, and aviation parts. CNC machining’s ability to combine metals with plastics makes it possible to craft hybrid parts that stand up to military specifications for durability and precision.

Applications for Military Manufacturing in Durham, NC

Custom prototyping and production for military applications demand the highest standards across various sectors. Roberson Machine Company’s precision machining capabilities provide solutions that meet the exacting needs of military-grade equipment, supporting:

- Aerospace: By employing precision CNC milling and 5-axis machining, we produce intricate, high-strength components that are lightweight and built to withstand the demanding performance and safety standards required for combat and tactical aircraft.

- Military Vehicles: CNC turning and aluminum machining create durable, high-performance components built to withstand challenging terrain and rigorous field testing. These parts enhance reliability and safety in combat vehicles and transport fleets.

- Medical Devices: Our custom CNC milling services focus on producing field-grade medical devices for mobile and battlefield medical units. Every component is designed to meet strict regulatory standards, ensuring both sterility and reliability in critical, high-stakes environments.

- Industrial Manufacturing: Our CNC capabilities support the mass production of consistent, mission-ready parts. With strict compliance to quality management standards, we ensure high levels of quality and consistency across all components.

- Energy: Utilizing CNC turning, we create components critical for portable power solutions, enabling consistent energy supply systems designed for forward-operating bases and harsh operational environments.

Main Services for Durham, NC, Military CNC and Product Processes

- Anodizing: A method that applies a robust oxide layer to aluminum, offering heightened resistance against corrosion and wear for increased longevity.

- Heat Treating: A metallurgical process that applies heat and controlled cooling to refine and adjust the physical properties of metals, making them stronger and more resilient.

- Dimensional Inspection: A detailed measurement process focused on ensuring that parts conform to the exact dimensions and tolerances necessary for reliable performance.

- Powder Coating: A dry finishing process that applies a decorative and protective coating to metal surfaces, providing a durable and attractive finish while being environmentally friendly.

- Bead Blasting: A process involving high-pressure abrasive beads to prepare surfaces, enhancing adhesion for coatings while achieving a clean and polished look.

- Passivating: A specialized chemical treatment applied to stainless steel and other metals to create a corrosion-resistant layer, optimizing durability for rigorous environments.

- Engraving/Marking: A durable marking process that etches logos, identifiers, and specifications onto components, essential for traceability and meeting industry standards.

- Painting: A finishing technique that applies resilient coatings in various paint types, designed to improve appearance and provide added protection against environmental damage.

Advancements from these industries often translate into impactful military applications. Our mission is to turn your vision into reality by designing, developing, and delivering quality products that align with your objectives.

We also offer other Durham, NC, metal services, including:

- Medical Brace Manufacturing

- Manufacturing Oil & Gas Industry Parts

- 5 Axis CNC Machine

- Aluminum Aerospace Machining

- Medical Parts Manufacturer

- CNC Milling Aluminum

- Plastic Parts Manufacturer

- Precision Manufacturing

- Aerospace Machining

Why Choose Roberson Machine Company for Military Manufacturing in Durham, NC?

To ensure you receive quality products, we utilize several types of metals, including:

- Aluminum Grades: 6061, 7075, 7050

- Stainless Steel Grades: 303, 304, 316, 321, 420SS, 416, 440

- Plastics: Delrin, Nylon, PEEK, HDPE, and Glass-Filled Nylon

For additional insights, check out our blog. Below are some of the factors that set Roberson apart in military manufacturing:

- Wide-Ranging Material Expertise: Roberson Machine Company specializes in materials like aluminum, titanium, steel, and lightweight, durable plastics. This flexibility lets us create military components that achieve the highest standards of strength and efficiency for various applications.

- Exacting Tolerance Standards: With CNC machining precision, we meet the tight tolerances vital for military components, guaranteeing flawless performance in high-stakes applications.

- Manufacturing for Complex Geometries: Our expertise in multi-axis CNC machining allows us to create intricate components with complex geometries, essential for advanced military technology.

- Design Testing and Production: We take projects from prototype to production, using early-stage machining to test and improve designs before ramping up to large-scale manufacturing.

- Comprehensive Quality Control: Our process includes rigorous dimensional checks, as well as specialized treatments such as passivation, anodizing, and powder coating, ensuring each component’s durability and precision.

Contact Roberson’s Durham, NC, Military CNC Manufacturing Specialists

Ensuring adherence to military standards is a top priority at Roberson Machine Company. Our team actively engages in continuous training, industry seminars, and workshops to stay aligned with the latest regulations and best practices. By building strong connections with military personnel and regulatory experts, we maintain a thorough understanding of compliance requirements. This dedication to quality and precision ensures that every component we manufacture meets the high safety and performance standards crucial for military applications.

For inquiries about military manufacturing in Durham, NC, our CNC milling capabilities, or to learn more about what we offer, feel free to call us at 573-646-3996 or reach out online.