CNC Turning in Salinas, CA, is a precision machining process used to produce round, cylindrical, and rotational components with controlled diameters, bores, threads, and concentric features. CNC turning supports repeatable, production-ready parts at Roberson Machine Company from initial runs through ongoing releases.

Learn more about:

- How CNC turning fits into production-scale part manufacturing

- How turning and multi-axis machining work together

- Industries where turned features play a critical role

- How to take the next step on a CNC turning project

CNC turning plays a role across medical, aerospace, automotive, automation, and industrial equipment manufacturing, supporting both high-volume cylindrical components and parts that combine turning, drilling, and milled features in a single workflow—including many everyday machinery components produced at scale. We support short-, medium-, and long-run CNC turning programs across a broad mix of materials and part geometries. To talk through your Salinas, CA, CNC Turning project, contact us online or call 573-646-3996.

Table of Contents

- What CNC Turning Does Best in Production

- Industries That Rely on CNC Turning

- When CNC Turning Is the Right Method for Part Production

- CNC Turning & Precision Machining Capabilities

- Frequently Asked Questions | CNC Turning

- Why Choose Roberson Machine Company for CNC Turning in Salinas, CA?

To learn more about how Salinas, CA, CNC turning fits into real production environments, explore our case studies, blog, FAQs, and customer reviews. These resources demonstrate how turned features and multi-axis machining are applied across a variety of real-world applications.

What CNC Turning in Salinas, CA, Does Best in Production

CNC turning occupies a specific place in modern manufacturing by producing accurate, repeatable geometry on parts where round features, concentric relationships, and surface control drive performance. In production settings, turning produces the diameters, bores, threads, and functional surfaces that other operations depend on, frequently within larger contract manufacturing workflows.

When implemented correctly, CNC turning supports reliable workflows across short runs, high-volume production, and repeat releases. To scale output without introducing variation, Roberson Machine Company relies on CNC turning as the foundation that supports downstream milling, assembly, inspection, and quality control.

Establishing Critical Diameters & Concentric Geometry

CNC turning is commonly used to establish the core geometry that defines part function. Diameters, bores, shoulders, threads, and sealing surfaces are created relative to a single rotational centerline, allowing turning operations to control concentric geometry and reduce runout.

This approach is essential for parts and assemblies where geometry needs to stay aligned throughout production and use, including:

- Rotational features that need to remain aligned through assembly

- Interfaces between bearings, seals, and mating components

- Parts that are built around consistent centerlines across operations

By keeping features anchored to a shared axis, Salinas, CA, CNC turning experts minimize stack-up errors and maintain critical relationships. That foundation allows downstream milling, cross-drilling, and secondary operations to add features without affecting fit or function.

Achieving Repeatability Across Volume & Release Cycles

In production machining, repeatability, rather than accuracy alone, is what turns a successful first run into a dependable process. CNC turning supports repeatability by keeping key variables controlled and consistent from part to part, which becomes especially important when moving from initial runs into mass production.

Holding geometry to a consistent rotational centerline

By referencing critical features to a single axis, CNC turning helps maintain alignment of diameters, bores, threads, and sealing surfaces across every part in a run. This matters most in real-world applications where components must interface cleanly with bearings, seals, housings, or rotating assemblies as parts scale from prototype quantities into production volume.

Using stable workholding and repeatable setups

Reliable fixturing and workholding minimize variation between parts and from run to run. When setups stay consistent across releases, CNC turning can maintain dimensional stability as production scales or schedules change.

Applying the same tool paths, offsets, and cutting conditions

Consistent programming and controlled cutting parameters help limit variation caused by operator changes, setup drift, or gradual process changes as production scales. Over long production runs, issues such as machine drift can compound when programs, offsets, or setups aren’t consistently maintained.

That repeatability helps manufacturers plan production with confidence and avoid rework when parts are released again months—or years—later. When applied with a production mindset, Salinas, CA, CNC turning provides a reliable foundation for scaling output—whether parts are produced internally or as part of a broader contract manufacturing strategy.

Efficient Production of Cylindrical and Rotational Parts

CNC turning is built to efficiently produce cylindrical and rotational parts. When functional requirements center on diameters, bores, threads, and axial features, turning removes material in a continuous, controlled motion that reduces cycle time, non-cutting time, and excess tool movement.

In production settings with repeat parts, bar-fed stock, single-axis rotation, and one-setup machining enable CNC turning to maintain consistent geometry while cutting down on handling and re-clamping. These advantages align closely with production-driven CNC methods that prioritize throughput and process stability.

- Shafts, pins, and rotational hardware designed to transfer motion and hold consistent diameters across extended runs.

- Bushings, sleeves, and wear components where alignment and surface finish play a key role in service life and fit.

- Rollers and cylindrical tooling applied in continuous-duty equipment that cycles and requires scheduled replacement.

- Turn–mill hybrid parts that combine rotational geometry with milled features completed in a single setup.

For these types of components, Salinas, CA, CNC turning delivers the balance of speed, accuracy, and process control needed for both short production runs and long-term manufacturing programs.

Industries in Salinas, CA, That Rely on CNC Turning

CNC turning serves an essential role across industries where rotational geometry, concentric features, and controlled surface finishes directly affect performance, safety, or service life.

Medical & Regulated Manufacturing

Across medical machining and manufacturing, CNC turning commonly produces the features that seal, align, or interface with other components. Small deviations in diameters, bores, or surface finishes can impact fit, function, and downstream inspection outcomes.

Turned components are used in precision valve bodies, microscope and alignment assemblies, precision housings, and small-scale medical instrument parts where concentric geometry and surface control matter more than raw material removal speed.

Automotive and vehicle machining and EV manufacturing depend on CNC turning for high-volume components where diameters, threads, and concentric relationships must remain consistent across thousands—or millions—of parts.

- Processes that need to stay stable as production scales

- Features that interact repeatedly with bearings, seals, and mating components

- Geometry that should not drift between initial release and long-term production

You see this reality in production work where drive shaft components must hold dimensional control over extended runs, and minor changes in geometry can create downstream assembly and performance issues in automotive production.

Industrial Automation, Robotics & Production Equipment

Across automated and robotic systems in industrial manufacturing, turned components are built to cycle continuously, align precisely, and wear in predictable ways. CNC turning supports bushings, guides, rollers, and hybrid turn–mill parts that integrate directly into automated systems where downtime is expensive and replacement parts need to drop in without adjustment.

This is most evident in assemblies like end-of-arm robotic tooling, where concentric geometry, mounting alignment, and repeatability directly impact positioning accuracy and cycle performance.

Aerospace & Defense

Rigorous performance and verification requirements define aerospace machining and defense manufacturing, where CNC turning supports components that permit no geometric drift or process variation.

- Load & mechanical stress: Turned features must hold alignment and dimensional stability when subjected to sustained and cyclic loading.

- Vibration & dynamic forces: Rotational components must withstand runout and surface degradation that can increase vibration during operation.

- Long service cycles: Geometry and finishes must remain consistent over long service cycles where wear, fatigue, and thermal exposure accumulate.

- Process control & traceability: Turning operations are required to repeat cleanly across validated releases and documented production runs.

Salinas, CA, CNC turning delivers the control and process stability needed to meet these constraints over extended service lives.

Energy, Oil & Gas

Within energy and oil & gas machining environments, turned components are subjected to pressure, heat, wear, and corrosive service conditions. CNC turning is used for components where geometry, material behavior, and surface integrity directly affect long-term service life.

- Pressure and fluid containment: Turned valve components and manifolds need to maintain concentric alignment and sealing performance across repeated pressure cycles, which are central considerations in what matters most in oil & gas CNC machining.

- Wear, heat, and material stress: Continuous exposure accelerates failure when geometry drifts or finishes degrade, which is why precision machining plays a role in reducing waste during long production cycles.

- Surface durability: Long-term performance can hinge on post-machining decisions such as surface treatments designed to improve resistance to corrosion, abrasion, and harsh operating conditions.

CNC turning offers the process control necessary to meet these demands without introducing variability across extended production runs, particularly where heat, pressure, and material behavior introduce additional operational and safety considerations.

When CNC Turning Is the Right Method for Part Production

In Salinas, CA, CNC turning is often the right method when part performance depends on rotational accuracy, concentric relationships, and controlled surface finishes.

From bushings and pins to rollers and turn–mill tooling equipment, CNC-turned parts tend to require:

- Specific diameters, bores, rotational geometry, or axial features that define how components align, seal, or rotate.

- Features that must hold concentricity to a shared centerline across operations, assemblies, or service cycles.

- Surface finishes that directly impact how parts interact with bearings, seals, fluids, or wear surfaces.

- Geometry that must repeat reliably from first article through long production runs and future releases.

- Multiple features that benefit from single-setup completion to preserve alignment between turned and milled elements.

Production Use Cases for CNC Turning

These requirements surface repeatedly across a range of production environments. Common CNC turning parts include:

- Sealing, flow, and pressure-handling parts: Precision valve bodies, fluid-handling components, and turned features used in environments where sealing performance is a priority.

- Alignment-critical components: Bushings, sleeves, housings, microscope parts, and sensor mounts that must align accurately during assembly.

- Motion-transfer and drive components: Shafts, pins, and rotary hardware produced at scale, including drive shaft components.

- Continuous-duty rollers and cylindrical tooling: High-cycle rollers and guides, including ink rollers, used in production and packaging equipment.

Turned components don’t always exist on their own. Rotational features are frequently combined with milled flats, slots, or mounting interfaces, making CNC turning an essential foundational step in broader machining workflows.

CNC Turning & Precision Machining Capabilities

Many CNC-turned parts require additional machining operations to support functional features, alignment, or reduced downstream handling. At Roberson Machine Company, CNC turning operates within a broader workflow designed for repeatability and release consistency.

Based on how the part is designed, Salinas, CA, CNC turning often draws on a range of CNC machining capabilities:

- CNC Milling — Non-rotational features such as flats, pockets, and slots added as secondary operations after turning.

- Precision CNC Machining — For secondary features, dimensional refinement, and finishing after turning.

- Multi-Axis CNC Machining — To preserve alignment of cross-holes and angled features without additional setups.

- 5-Axis CNC Machining — Used when parts demand access from multiple orientations without rehandling.

- Wire EDM — Used for hardened materials or internal profiles not practical to machine conventionally.

- Prototyping & First-Article Production — To validate designs before repeat or long-term production.

When CNC turning in Salinas, CA, requires multiple operations, the objective is clear: Complete the part efficiently, maintain alignment between features, and avoid unnecessary handoffs.

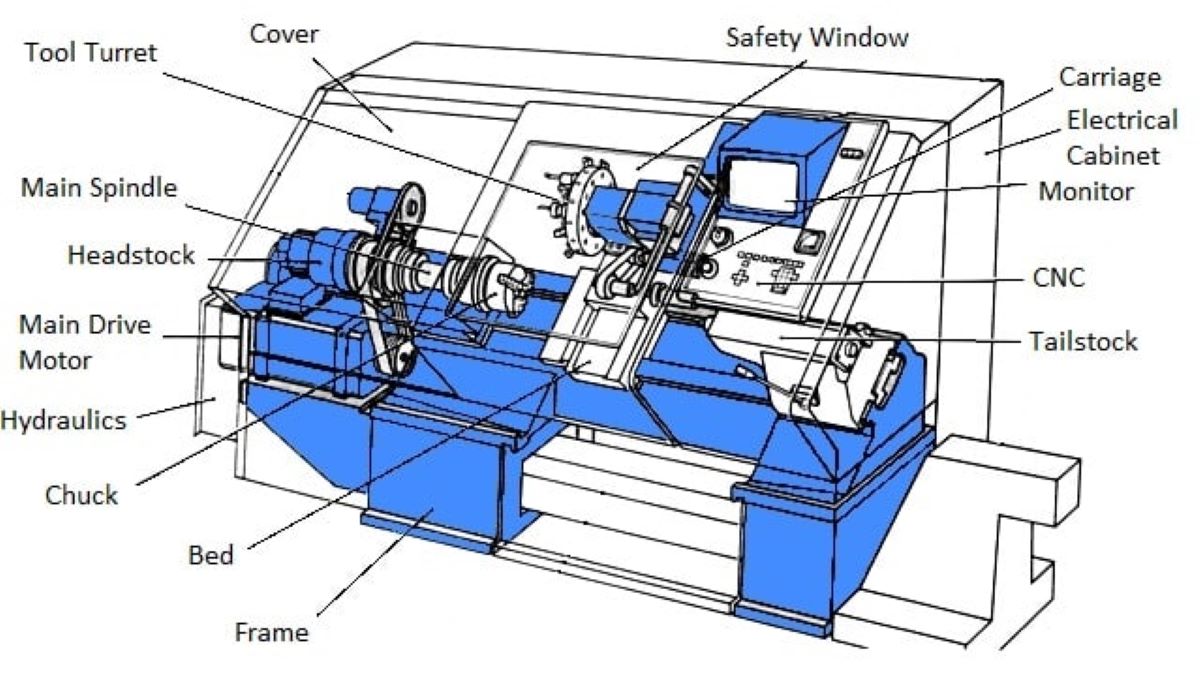

Lathe Machines vs. Turning Centers

CNC lathes and CNC turning centers handle turning operations, but they support different needs in production environments. The difference centers on capability, automation, and how much work can be completed within a single setup, not age or appearance.

CNC Lathes

Run on two axes (X and Z) and are commonly used for straightforward turning work. Traditional CNC lathe machining fits parts that require consistent diameters, faces, grooves, or threads without complex secondary features.

CNC Turning Centers

Live tooling, added axes, sub-spindles, and automated tool handling allow turning centers to go beyond basic turning operations. CNC turning centers can drill, tap, mill, and back-work parts in a single setup—reducing handoffs and preserving alignment between features.

The right choice depends less on machine complexity and more on how efficiently a part can be completed from start to finish—an important consideration when choosing a CNC turning partner in Salinas, CA, for production work.

Frequently Asked Questions | Part Production & CNC Turning in Salinas, CA

When CNC turning is evaluated for production, the key considerations are typically fit, scale, and long-term consistency. These FAQs explain how turning supports production requirements in practice.

When does CNC turning in Salinas, CA, become the right choice for production work?

CNC turning is best suited for parts whose function depends on rotational accuracy, consistent diameters, or features that must stay aligned to a common centerline.

It’s especially well suited for parts that repeat at volume, need predictable surface finishes, or serve as the geometric foundation for additional machining operations.

What types of production parts are commonly made with CNC turning?

CNC turning in Salinas, CA, is frequently used for production components such as:

- Shafts, pins, and rotational hardware

- Bushings, sleeves, and wear components

- Valve bodies, manifolds, and flow-control parts

- Rollers and cylindrical tooling for automated equipment

- Turn–mill components that combine rotational and milled features

These types of parts commonly perform alignment, sealing, or motion-transfer roles within larger assemblies.

What inputs matter most when quoting a CNC turning project?

Reliable quotes are based on understanding how the part will be produced and released over time. Helpful inputs include:

- Current drawings with tolerances and critical feature callouts

- Material specifications and finish requirements

- Expected quantities per release and annual volume

- Delivery cadence or production schedule

- Inspection, documentation, or packaging expectations

If some details are still evolving, early discussion often helps refine the manufacturing approach before pricing is finalized.

What commonly affects pricing for CNC turned parts?

Cost is usually influenced by how efficiently a part can be produced and repeated. Common drivers include:

- Setup complexity and number of required operations

- Tight tolerances or surface finish requirements across many features

- Material behavior, chip control, and tooling wear

- Cycle time impacted by milling, drilling, or back-working

- Release sizes that repeat setup effort too frequently

Reviewing functional requirements early can often reveal opportunities to reduce cost without affecting performance.

How is consistency preserved across high-volume or repeat CNC turning runs?

Maintaining consistency depends on controlling the process rather than relying solely on first-run qualification. This usually involves standardized workholding, documented tooling and offsets, in-process checks on critical features, and inspection routines aligned with print requirements.

Once a turning process is validated, those controls keep parts consistent across future releases—even months or years later.

When is it beneficial to combine CNC turning in Salinas, CA, with milling or secondary processes?

Many production components start with turning for core geometry and then use milling or other processes for additional features.

The approach is especially effective when milled features must remain aligned to turned geometry, or when consolidating operations reduces handling and setup variation.

How early in the process should a machining partner be involved for CNC turning?

Earlier involvement creates more room to optimize the process before cost, lead time, or repeatability issues get locked in.

- Material and stock selection

- Tolerance strategy on functional features

- Setup count and operation sequencing

- Whether parts can be completed in a single workflow

Even when prints aren’t final, those conversations usually prevent avoidable changes later.

Is Salinas, CA, CNC turning capable of supporting both low-volume and long-term production programs?

CNC turning is well suited for early production, bridge quantities, and long-term repeat programs.

The difference isn’t volume—it’s whether tooling, workholding, and inspection plans are built with future releases in mind. When planned correctly, the same turning process can scale without requiring a rebuild later.

How inspection supports Salinas, CA, CNC turning for production parts?

Inspection helps verify that the turning process is holding critical features consistently, not just meeting a one-time result.

- Critical diameters, bores, and threads

- Relationships between concentric features

- Consistency across lots and releases

The goal is confidence and stability, not checking every feature on every part.

What’s the difference between repeat releases and continuous production runs?

Repeat releases add time gaps that make process control more important than raw speed.

- Documented setups and tooling

- Controlled offsets and tool life

- Clear inspection benchmarks

With those controls in place, production can restart months or years later without drifting from the original intent.

What distinguishes production-ready Salinas, CA, CNC turning from job-shop turning?

The difference isn’t the equipment—it’s the mindset guiding the process.

Rather than completing isolated jobs, production-ready turning centers on stability, documentation, and repeatability across releases. That focus is reflected in programming, workholding, inspection strategy, and scheduling discipline.

Why Choose Roberson Machine Company for Salinas, CA, CNC Turning?

Process control, equipment, and production experience come together at Roberson Machine Company to support reliable, repeatable CNC turning. Stable workflows and tooling strategies allow us to support long-term production cycles while keeping releases on schedule.

After CNC turning moves beyond prototype stages and into repeat production, execution matters more than raw capability. Process control, setup discipline, and production experience are what keep parts consistent and programs on track. Our team at Roberson Machine Company specializes in:

- Turning workflows engineered to maintain critical diameters, bores, and sealing features across repeat releases

- Single-setup machining strategies that limit handoffs, cycle time, and alignment risk

- Process control that ensures part consistency from first article through extended production runs

- Material experience across stainless, aluminum, alloys, titanium, and production-grade polymers

- Scheduling discipline paired with tooling strategies to minimize scrap, delays, and downstream variation

Additional CNC services we provide include:

- CNC Lathe Machining

- Custom CNC Machining for Part Production

- CNC Machine Automation

- Oil and Gas Precision Machining

- Aerospace Manufacturing

- Automotive Part Manufacturing

- EDM Machining

- High Volume CNC Machining

- Industrial Automation

- Solar Panel Manufacturers

New releases, scaled production, and ongoing CNC turning programs are supported by Roberson Machine Company with a focus on consistency and long-term reliability. Learn more about our team and capabilities, request a quote online, or call 573-646-3996 to talk through your Salinas, CA, CNC Turning project and production requirements.