CNC turning Fresno, CA. Positioned as a premier manufacturer specializing in precision-machined components, Roberson Machine Company proudly offers unparalleled CNC turning services. Operating at the forefront of technological innovation, our CNC turning services not only ensure swift production, but, more importantly to your Fresno, CA company, deliver results characterized by unrivaled accuracy and excellence. This distinction helps separate us from our industry counterparts in Fresno, CA and across the country.

Equipped with extensive facilities encompassing thousands of square feet housing cutting-edge CNC turning centers, lathes, and state-of-the-art CNC machining technologies, we possess the capability to efficiently produce batches ranging from ten to tens of thousands of identical parts. This holds true even when faced with the most exacting specifications. Our robust quality management system enables us to seamlessly navigate every stage of projects in Fresno, CA, from initial prototyping to the final shipping stage, ensuring optimal efficiency throughout the entire process.

Let us handle your Fresno, CA company’s short, medium, and long-run productions, along with any other machining needs you may have. To discuss your CNC turning project in more detail or to find out about partnering with Roberson Machine Company, give us call as soon as possible at 573-646-3996 or contact us online for a free quote.

CNC Turning For Your Fresno, CA Company

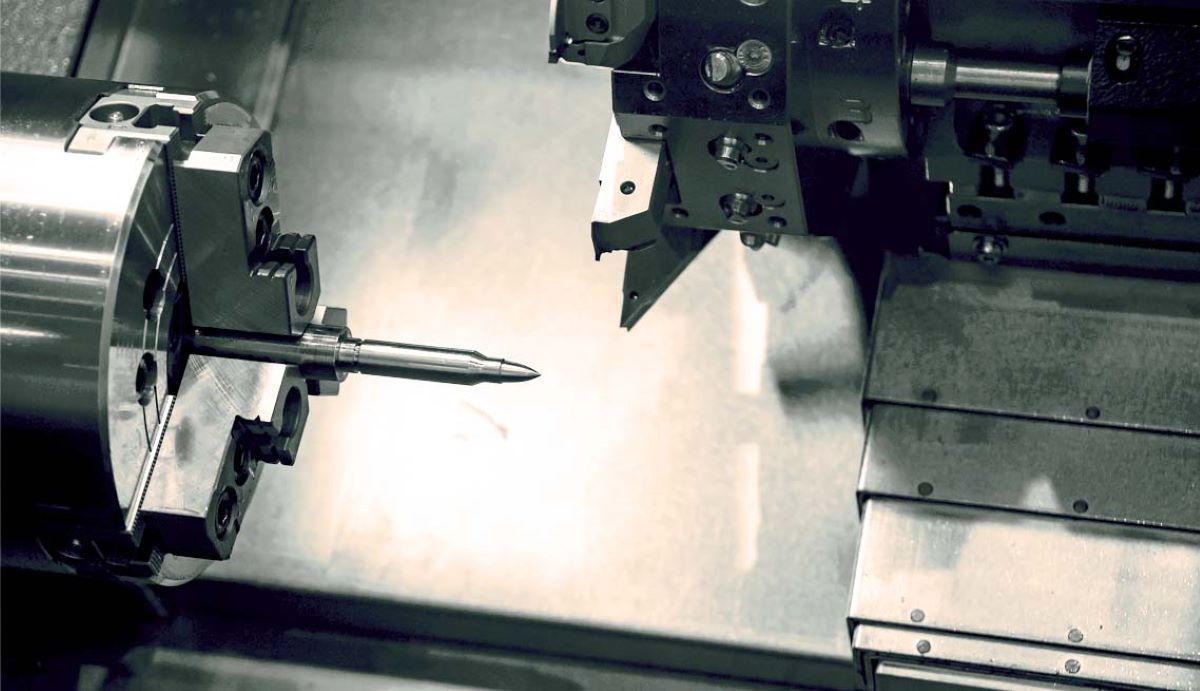

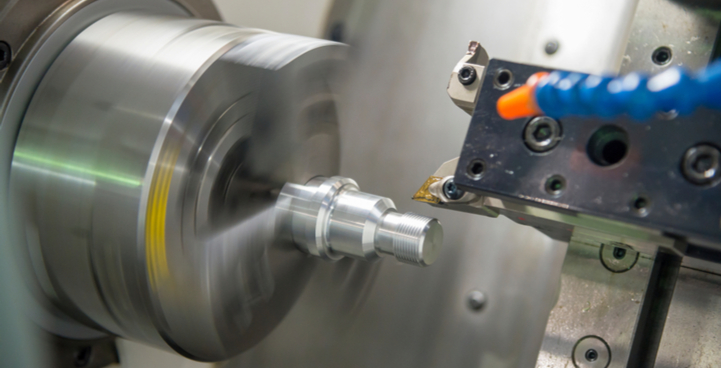

CNC turning is a subtractive manufacturing process where, controlled by CAD and CAM software inputted by our experts, a CNC lathe removes material from a rotating workpiece to achieve precise shapes and dimensions. This automation allows us to create complex geometries with unparalleled accuracy.

Our Fresno, CA partners come to us for CNC turning projects rooted in a variety of materials – metals, alloys, plastics, composites, and other polymers. We specialize in horizontal CNC turning, which is an intricate, rapid method of creating custom parts for many different applications.

Our premier turning services include:

- Hard turning

- Long turning up to 48 inches in length

- Tight tolerances

- Short lead times

Let us be your valued partner for CNC turning services. Contact our skilled team now or give us a call at 573-646-3996 to get a quote started.

The Differences Between a Lathe Machine and a Turning Center For Your Fresno, CA Project

Equipped with both CNC lathes and CNC turning centers on our factory floor, we possess the capability to produce any part for your Fresno, CA company. However, it’s important to understand the key distinctions between the two:

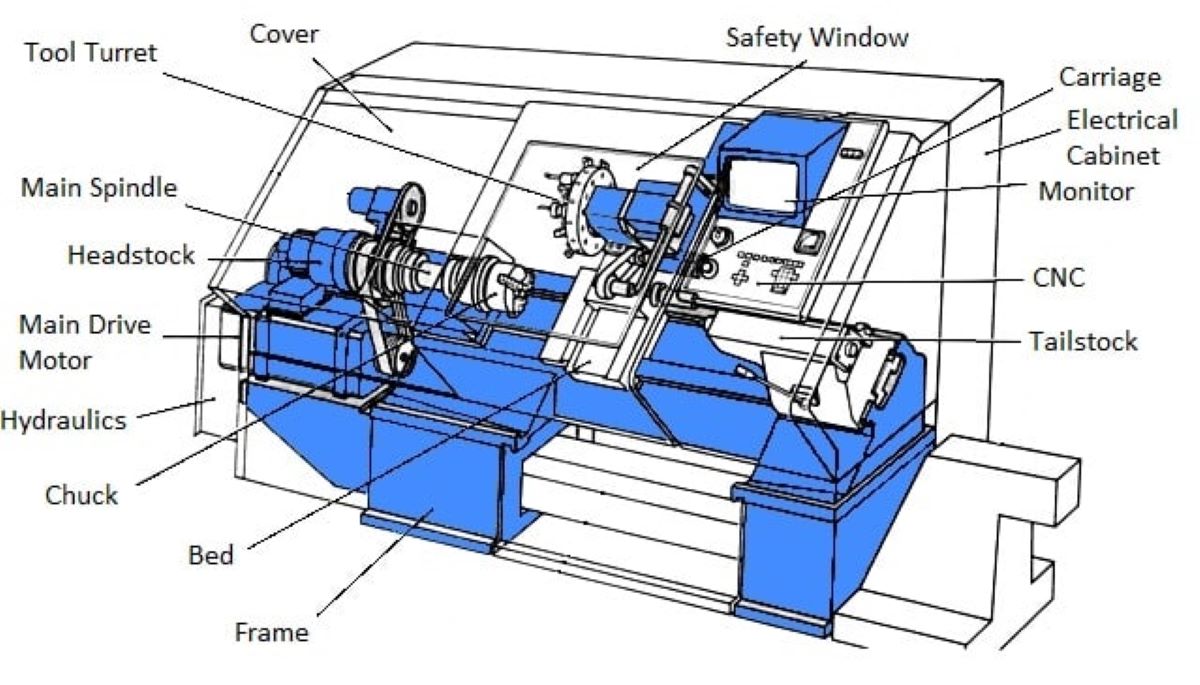

Our lathe machines are characterized by two axes (X and Z), a single spindle, and can be of the flat-bed type, making them generally easier machines.

Our CNC turning centers can have multi axis machining – 3, 4, or even 5 axis machining (including a Y axis) – as well as sub-spindles and multiple turrets. They are commonly slant-bed type and have full-machine enclosures to keep coolant splashes and chips inside the machine. These types of machines may be able to provide more versatile capabilities and applications, such as turning, drilling, tapping, and milling. Also, because they are completely automated, a turning center can move on all axes simultaneously with exceptional precision.

A turning center can come in both horizontal and vertical structures, with horizontal being the most common for a number of reasons. In these types of applications, the spindle is oriented horizontally, and tools are mounted out of the side of the tool holder which cut across the workpiece. Gravity causes the metal chips to fall to the bed below, maintaining a clean workpiece during cutting.

Key Advantages For Your Fresno, CA Company of CNC Turning at Roberson Machine Company

CNC turning is a process that “turns” the workpiece while metal is shaved away in a quick series of motions, allowing us to produce a large number of well-finished, identical components in a short period of time. Using a manufacturing technology that dates back to the Egyptians, a bar of material is held on a chuck that rotates at a high speed while a single-point tool cuts into it to machine the desired end shape.

CNC turning works best in these situations:

- Your part has diameters or is round, tubular, or cylindrical in shape

- You require a high volume of parts in Fresno, CA

- You operate under stringent time constraints in Fresno, CA

- You need the flexibility to create designs ranging from straightforward to complex

- You demand consistency, with each piece conforming to precise specifications

The Benefits of Opting For Roberson Machine Company Include:

- Precision Manufacturing: Our CNC turning ensures exceptional precision, meeting tight tolerances and intricate design specifications. The automated nature of CNC turning at our facility eliminates the variability associated with manual processes, ensuring consistent and high-quality results for your parts in Fresno, CA.

- Complex Shapes and Patterns: Our CNC turning services excel in machining complex shapes, intricate patterns, and contoured surfaces. This capability is particularly vital in industries where precision is non-negotiable. Give us a call now at 573-646-3996 or reach out to us online.

- Efficiency and Speed: The automated efficiency of CNC turning at Roberson Machine Company substantially reduces production time. With multiple axes of movement, we enable simultaneous machining, enhancing efficiency for your company in Fresno, CA without compromising accuracy.

- Economical Production Runs: We keep initial setup costs low, making our Fresno, CA CNC turning services cost-effective for all-sized production runs. Reduced material waste and efficient machining by our experts contribute to your overall cost savings.

Along with CNC turning, our skilled specialists provide the following machining solutions for your Fresno, CA company:

- Aerospace Manufacturing

- Automotive Part Manufacturing

- EDM Machining

- High Volume CNC Machining

- Industrial Automation

- Solar Panel Manufacturers

- Microscope Parts Precision Machining

- Military Manufacturing

- Medical Brace Manufacturing

Applications for CNC Turned Parts From Roberson Machine Company

Whether your Fresno, CA CNC turning project involves bars, tubes, gears, knobs, pulleys, flanges, shafts, bushings, or other components, Roberson Machine Company is the place to turn. Give us a call today at 573-646-3996 or reach out to us online to receive a quote and find out how we can assist in these sectors and more:

- Automotive – CNC turning produces critical components for the automotive industry, including shafts, pulleys, and connectors with precision and efficiency.

- Medical and Medical Devices – Our CNC turning services benefit the medical sector by machining parts for implants, surgical instruments, and other intricate medical devices.

- Aerospace – In the aerospace sector, where stringent tolerances are crucial, CNC turning is used for producing components such as turbine parts and landing gear.

Reach Out to the Fresno, CA CNC Turning Pros at Roberson Machine Company Right Away

When evaluating manufacturing processes for your Fresno, CA project and selecting the ideal company to partner with, CNC turning at Roberson Machine Company should be at the top of your list, especially for applications demanding precision, efficiency, and material versatility. We are able to choose the right machining service to meet your production targets on time and within budget. Collaborating with our skilled and experienced CNC turning specialists guarantees the translation of your Fresno, CA part designs into high-quality, accurate components that align with your specifications and help you achieve sustainable success.

Call us right now at 573-646-3996 or get a quote by reaching out to us online.