High Volume CNC Machining Independence, MO

High Volume CNC Machining Independence, MO. With over 20 years of experience, Roberson Machine Company has been a trusted leader in delivering precision high-volume CNC machining services to numerous industries. Interested in high-volume precision machining? Our nationwide capabilities allow us to consistently provide exceptional results. Call us today at 573-646-3996 or contact us online to explore how Independence, MO, High Volume CNC Machining can assist with your upcoming project.

What is High Volume CNC Machining?

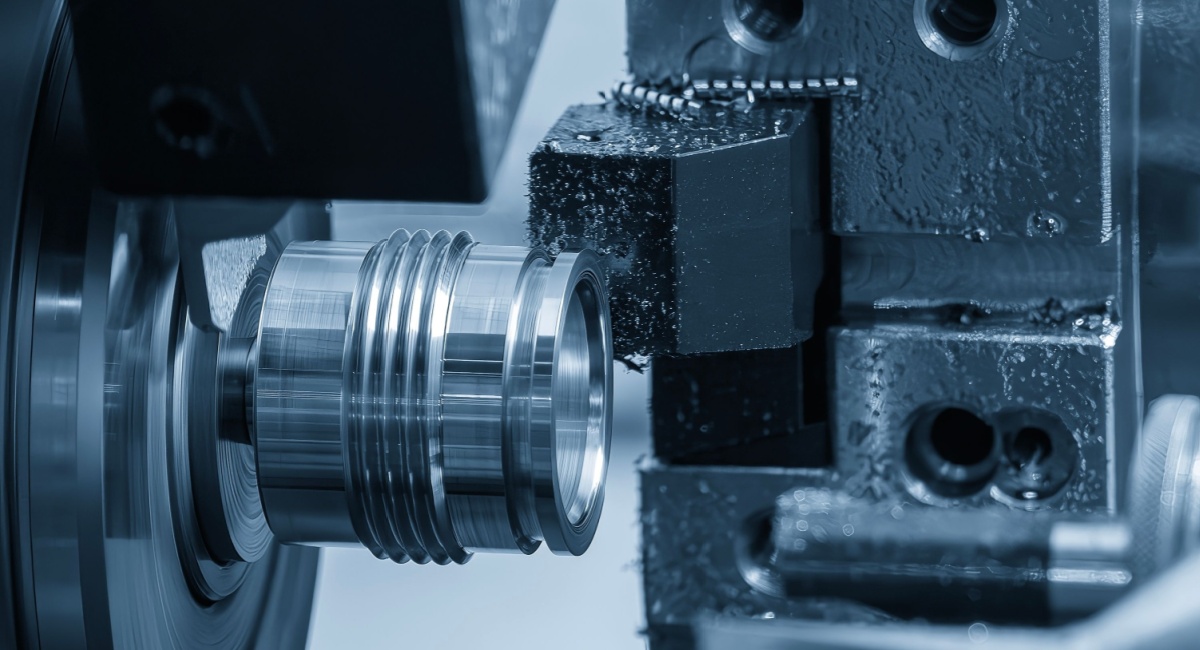

Through CNC machining, skilled technicians program machines to operate with extreme accuracy. This advanced manufacturing method enables the large-scale production of gears, high-precision tools, and essential industrial parts.

CNC machining is more than just a mass production tool—it enables high-precision fabrication that enhances efficiency, consistency, and scalability. From aerospace and medical components to custom automotive parts, CNC machining delivers exceptional repeatability while adhering to ISO 9001- and AS9100-based standards. Industries like defense, robotics, and electronics depend on its accuracy for mission-critical applications. With machining options such as milling, turning, and multi-axis techniques, manufacturers achieve the ideal combination of speed, precision, and material utilization.

Our High Volume CNC Machining and Milling Services for Independence, MO, Companies

At Roberson Machine Company, we offer industry-leading CNC machining services designed for precision and efficiency. Whether for high-volume production or intricate custom parts, our expertise guarantees accurate and consistent results.

At Roberson Machine Company, we provide precision machining solutions for industries such as aerospace, medical, and defense. Whether you need high-volume manufacturing or custom prototyping, our technology ensures superior results. See our core services below:

- Precision CNC Machining: Ensuring pinpoint accuracy for the most challenging parts.

- CNC Turning: Perfect for creating round, cylindrical parts with high precision.

- Aluminum CNC Machining: Crafting lightweight, durable aluminum components with precision.

- Prototype Machining: Speedy prototyping services to efficiently bring your designs to life.

- 5-Axis CNC Machining: Perfect for producing complex, high-precision components with multi-axis technology.

- Multi-Axis CNC Machining: Ideal for manufacturing intricate parts using various cutting angles for enhanced detail.

- Wire EDM: Precision cutting for hard materials, perfect for tight tolerances and intricate designs.

Customization is a core feature of high volume CNC machining and prototyping for one-off components. Through the use of CAD (Computer-Aided Design), CAM (Computer-Aided Manufacturing), and other advanced software and technology, we deliver high-quality precision parts and components.

A few of the more popular types of materials we work with include:

- Aluminum Alloys

- Stainless Steel

- PLAs, PETG, and Other Plastics

Get in touch with our team today to learn more about how we can help with your next Independence, MO, high volume CNC project.

Independence, MO, Industries That Utilize Precision High Volume CNC Machining

From food and beverage to packaging, industries across various sectors benefit from the mass production capabilities of CNC machining and milling. Offering sustainability, cost-effectiveness, and high-volume output, CNC machining is the key to delivering precise and high-quality products.

Below are a few of the core industries that rely on high volume CNC machining for cost-effective, efficient parts.

Automotive

The automotive production process relies on CNC machining to manufacture parts that adhere to high standards of safety and reliability.

- Engine Components: Essential components such as pistons, cylinder heads, and crankshafts for engine efficiency.

- Transmission Parts: Gearboxes, shafts, and clutch components designed for reliable transmission operation.

- Suspension Components: Components including control arms, steering links, and strut mounts that ensure vehicle control and comfort.

Aerospace

For the aerospace industry, CNC machining is crucial in producing parts that withstand harsh conditions, requiring exact precision to maintain safety and optimal performance in the air.

- Structural Components: Components like fuselage frames, wing spars, and bulkheads used in aerospace construction.

- Engine Parts: Turbine blades, compressor rotors, and exhaust nozzles designed for optimal performance.

- Landing Gear Components: Key components such as shock absorbers, struts, and axles critical to landing gear performance.

Medical

In the field of medical devices and implants, CNC machining ensures that every part is crafted with exact precision to meet functionality and patient safety standards. This includes manufacturing surgical robots, pharmaceutical production lines, and 3D printing. Learn more about how the medical industry benefits from CNC-machined automation components.

- Surgical Instruments: Scalpels, forceps, retractors, etc.

- Implants: Hip joints, knee replacements, and dental prosthetics.

- Prosthetics: Custom artificial limbs and prosthetic components designed for individual needs.

Oil and Energy

From oil and solar power to other energy production sectors, precision machining plays a crucial role in manufacturing durable, high-performance parts.

- Drilling Equipment Components: Critical parts such as drill bits, motors, and pumps designed to endure high pressure and stress.

- Pipeline Fittings: Precision-machined valves, flanges, and connectors designed for leak-proof, secure installations.

- Energy Generation Parts: Key components for turbines, generators, and power plants, crafted for maximum output and dependable operation.

Consumer Goods

For consumer and commercial goods and parts, CNC machining delivers high quality while prioritizing uniformity and efficient material management.

- Electronic Housings: Enclosures designed to protect devices including computers, phones, and medical technology.

- Appliance Parts: Functional parts like motors, gears, and other structural elements.

- Furniture Components: Tailored hardware and fixtures for custom designs.

Our Independence, MO, CNC machining services are built to deliver high-quality components with precision and efficiency. Call us at 573-646-3996 or contact us online today for a free consultation on your next project.

High Volume CNC Machining and Milling for Independence, MO, Companies

Providing value-added services for industries nationwide, Roberson Tool specializes in high-volume CNC machining and 3D-printed components that meet the most demanding specifications. From our St. Louis headquarters, we serve clients across the U.S., offering dependable shipping and fast order processing. Our dedicated team ensures precision, efficiency, and top-tier service, making us a trusted partner in manufacturing.

Independence, MO, manufacturers can expect quality, efficiency, and reliability. We offer a variety of services for Independence, MO, businesses that might need high volume CNC services, including:

- Custom CNC Machining for Part Production

- CNC Machine Automation

- Oil and Gas Precision Machining

- Aerospace Manufacturing

- Automotive Part Manufacturing

- EDM Machining

- Industrial Automation

- Solar Panel Manufacturers

- Microscope Parts Precision Machining

Get in touch with our team now at 573-646-3996 or reach out online for more information about High Volume CNC Machining in Independence, MO.