From engine components to dashboards and transmissions, Automotive Part Manufacturing in Nashville, TN, is a key service offering from Roberson Machine Company. With over 20 years of experience across many industries, we deliver accuracy, speed, and consistency.

We’ll cover a range of topics to get you a better understanding of how CNC machining and automotive part manufacturing intersect. This includes:

- Applications for CNC machining in the automotive parts industry

- Materials used in automotive CNC machining

- Types of machining used in the auto industry

- Benefits of choosing Roberson Machine Company

Call us today at 573-646-3996 or contact us online to request a quote for Nashville, TN, Automotive Part Manufacturing or learn more about our capabilities.

Nashville, TN, Automotive Part Manufacturing: Real-World CNC Applications

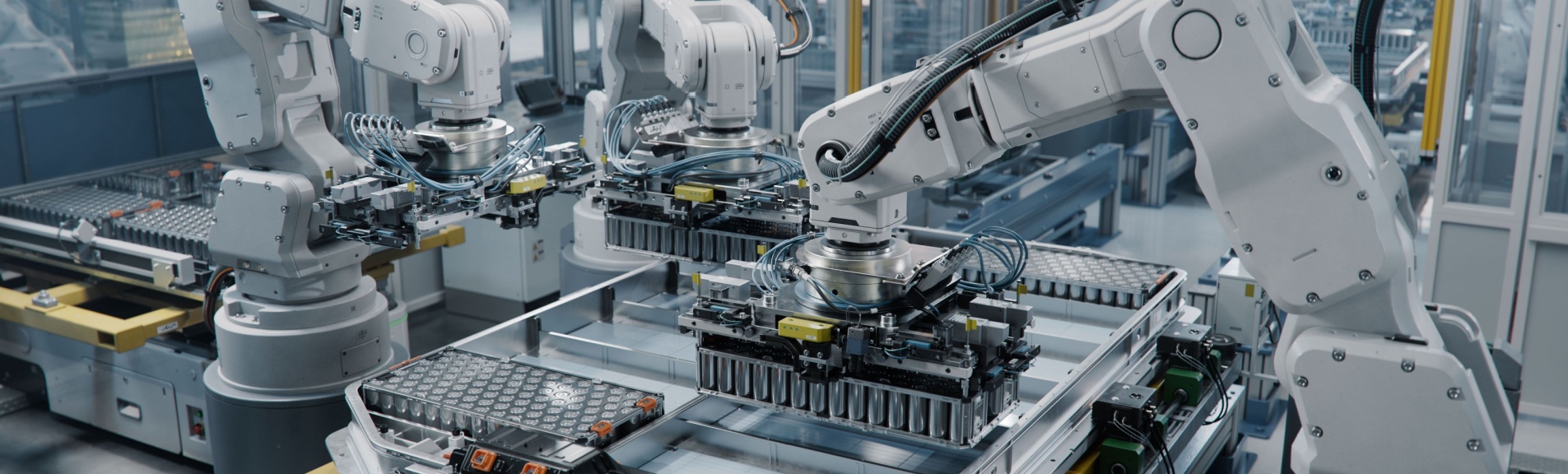

Engine components and custom brackets are just a few examples of parts where CNC machining plays an essential role in automotive manufacturing. Roberson Machine Company collaborates with Tier 1–3 Suppliers, small businesses, and various partners to deliver precise, scalable parts for production. In the automotive industry, CNC machining is commonly used for:

- Powertrain Components: Crankshafts, cylinder heads, and transmission housings must meet stringent precision standards to deliver peak performance, efficiency, and reliability. CNC machining ensures the tight tolerances needed for these vital parts.

- Suspension & Steering Systems: Key components such as control arms, knuckles, and linkages need to be lightweight, strong, and precisely machined. With Roberson’s expertise, each part is crafted to enhance handling and support long-lasting performance.

- Brake System Parts: From caliper mounts to rotors and pedals, these components are machined to meet stringent safety standards and ensure smooth braking. The right surface finish, tolerance, and geometry are crucial to maintain high braking performance.

- Interior & Dashboard Hardware: Not all parts are under the hood. CNC machining also supports aesthetic and functional components like gear shifters, infotainment brackets, and dashboard support structures.

- Prototyping & R&D: Prior to large-scale production, many automotive manufacturers rely on CNC machining to test the performance and safety of components. Roberson facilitates quick and precise transitions from CAD designs to real-world prototypes, aiding in design refinement and innovation.

- Electric Vehicle (EV) Components: As electric vehicle production accelerates, CNC machining is essential for creating complex parts such as battery housings, cooling plates, and custom mounts for electric drive units, all of which require innovative design and material solutions.

- Autonomous Vehicle Systems: In autonomous vehicles, precision-machined components such as sensors, control modules, and structural parts are crucial for ensuring the performance and dependability of advanced driving systems.

- Performance & Aftermarket Parts: With CNC machining, we craft custom performance parts such as intake manifolds, exhaust headers, and suspension upgrades, helping automotive enthusiasts enhance both the performance and appearance of their vehicles.

Roberson’s automotive manufacturing services are tailored to meet the industry’s demanding standards—whether you’re producing five parts or five thousand. Precision, consistency, and quality are our constant priorities.

Types of Materials We Use for Nashville, TN, Automotive CNC Manufacturing

In automotive manufacturing, material selection is key to ensuring the performance, safety, and longevity of vehicle components. At Roberson Machine Company, we leverage a diverse selection of metals and plastics, each chosen for its unique strengths—strength, weight, corrosion resistance, and machinability—to fulfill the precise needs of automotive applications. This includes:

- Aluminum (6061, 7075, 7050): Lightweight and corrosion-resistant, aluminum Alloys are commonly used for engine components, suspension parts, and housings. Higher-grade alloys like 7075 are often used for performance and motorsports.

- Stainless Steel (303, 304, 316, 321, 420SS, 416, 440): Stainless steels are prized for their strength and corrosion resistance, making them ideal for applications like exhaust systems, fasteners, and drivetrain components. For detailed insights on stainless steel, check out What Is Stainless Steel?. Hardened grades like 440 are especially known for excellent wear resistance.

- Plastics (Delrin, PETGs, Nylon, PLAs, PEEK, HDPE, Glass-Filled Nylon): These materials are ideal for lightweight, non-structural parts such as bushings, gears, and interior components. Certain types, like PEEK, are resistant to high heat and chemicals.

- Brass: With outstanding machinability and corrosion resistance, brass is the material of choice for fittings, bushings, and valves, particularly in fluid systems and connectors.

- Titanium: Known for its lightweight yet exceptional strength, titanium is ideal for performance-driven applications where the strength-to-weight ratio is crucial, including exhaust systems and racing components.

Our team is equipped with in-depth knowledge of automotive environments and can help you select the ideal material for every part—whether you’re working on prototypes or scaling up to full production. Reach out to explore our machining capabilities.

Key Services for Nashville, TN, Automotive Part Manufacturing

- Expert CNC Machining: Roberson Machine Company utilizes advanced technology and a highly skilled workforce to deliver precision components with tight tolerances and excellent surface finishes—key to the performance, safety, and reliability of automotive systems.

- Multi-Axis CNC Milling and Turning: From 3-axis to complex 5-axis machining, our capabilities allow for the creation of intricate geometries and detailed features found in modern engine, transmission, and suspension parts.

- Wire EDM: For precision cuts and complex internal designs, Wire EDM stands out for its unmatched accuracy, making it the go-to choice for specialty parts like fuel system components and precision brackets.

- From Prototype to High-Volume Production: We handle every stage of your project—from rapid prototypes for design validation to large-scale CNC production runs—ensuring quality and traceability throughout the process.

- Value-Added Services: Looking for more than just machining? We also provide welding, fabrication, deburring, bead blasting, and assembly to help streamline your supply chain and accelerate time to market.

From concept to completion, Roberson Machine Company delivers end-to-end CNC solutions designed for the automotive sector. Whether you’re in the prototype phase or preparing for large-scale production, we prioritize precision, efficiency, and quality at every step.

Why Choose Roberson Machine Company for Nashville, TN, Automotive Part Manufacturing?

When it comes to manufacturing precision products, Roberson is ready to assist. Here are a few compelling reasons to get in touch with Roberson Machine Company:

- Scalable Manufacturing Solutions: Engaging with our services provides a flexible approach to production without the financial burden of owning and operating manufacturing equipment. Our scalable solutions allow you to adjust production volumes as needed, optimizing costs and improving overall business agility.

- Tailored CNC Expertise: Take advantage of our decades of experience and specialized knowledge in CNC machining. We employ the latest techniques to deliver exact solutions for your project’s distinct requirements.

- Rigorous Quality Control: We deliver components that strictly adhere to automotive tolerances and specifications, with our certifications highlighting our commitment to quality.

- Long-Term Relationships: As your trusted partner, we prioritize transparent communication and reliable outcomes, ensuring strong relationships that last through every project, large or small.

- Focused Innovation: By entrusting us with your manufacturing needs, you can concentrate on design, performance, and market delivery, while we handle the production intricacies.

- Versatile Solutions: Our systems are designed to scale seamlessly from one-off prototypes to high-volume production. With experience across various industries, we pass along material and process savings to you.

Other services Roberson offers include:

- Oil and Gas Precision Machining

- Aerospace Manufacturing

- EDM Machining

- High Volume CNC Machining

- Industrial Automation

- Solar Panel Manufacturers

- Microscope Parts Precision Machining

- Military Manufacturing

- Medical Brace Manufacturing

Interested in learning more about CNC machining and automotive applications? Don’t hesitate to give us a call now at 573-646-3996 or contact us online for more information about Nashville, TN, Automotive Part Manufacturing and how our experts can help.