You can’t afford mistakes in Salisbury, MD, Aerospace Manufacturing. At Roberson Machine Company, we combine advanced high-precision CNC machining with detailed process control to deliver aerospace components that surpass exacting industry standards. From prototype machining to full-scale production, our team delivers consistent, reliable results across every phase of the Salisbury, MD, Aerospace Manufacturing process.

To learn more about our precision CNC services for Salisbury, MD, aerospace manufacturing, contact us online or call 573-646-3996 today.

Table of Contents

- Precision CNC Manufacturing for Aerospace Applications

- CNC Machining Services for Aerospace Manufacturing

- Aerospace Materials We Machine

- Why Aerospace Companies Work With Roberson

For insights on Salisbury, MD, aerospace machining and other CNC services, check out our blog.

Precision CNC Manufacturing for Aerospace Applications

Aerospace parts don’t get second chances. Whether it’s a flight-critical bracket or a complex engine housing, every component demands precision from the first cut to final inspection.

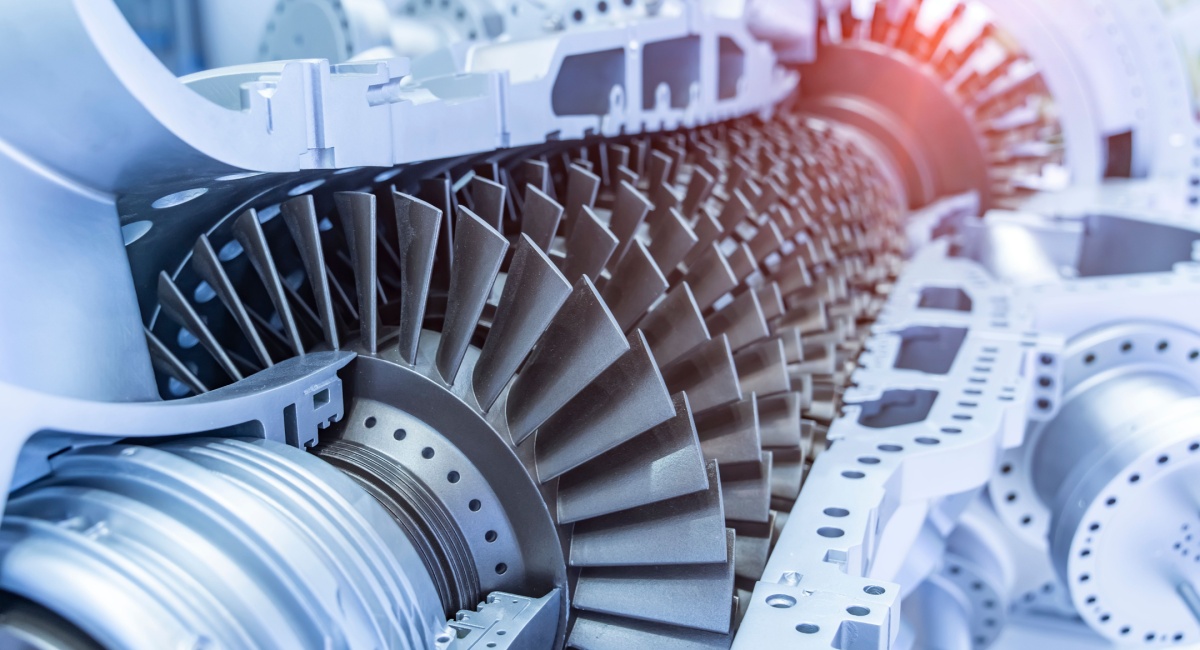

We help aerospace and defense companies machine high-precision parts for critical systems — from prototype to production. Our CNC capabilities are ideal for complex geometries and tight-tolerance components, such as:

- Structural brackets and supports, including roller-lift system components

- Avionics enclosures and mounts

- Hydraulic and fuel system housings

- Engine and propulsion system components

- Satellite and space hardware

- Flight control assemblies

From tight tolerances to exotic materials, aerospace components demand precision. Our shop is equipped to meet those challenges head-on, every step of the way.

CNC Machining Services for Aerospace Manufacturing

Our aerospace manufacturing solutions utilize advanced CNC technology to guarantee the precision and repeatability needed for flight-critical parts. We handle everything from prototyping through full production.

5-Axis CNC Milling

Our 5-axis milling equipment allows us to machine complex aerospace geometries in a single setup, improving accuracy and reducing cycle time. Ideal for structural components, housings, brackets, and aerodynamic surfaces with compound angles.

Multi-Axis CNC Turning

Our multi-axis lathes manufacture high-precision shafts, bushings, pins, and rotational parts, ensuring tight concentricity and roundness. They handle simple to complex aerospace turning in one pass.

Wire EDM Machining

For intricate features, internal geometries, and heat-sensitive aerospace alloys, Wire EDM provides burr-free, high-precision cutting, particularly useful for fuel systems, small engine parts, and fine-tolerance components.

Prototype Machining

With rapid-turn prototype machining, we assist aerospace customers in development, qualification, and testing by enabling engineers to evaluate form, fit, and function ahead of production.

Precision CNC Machining

Our commitment to strict process controls ensures dimensional precision, consistent repeatability, and superior surface finishes throughout all services, meeting aerospace industry standards. Every part is thoroughly inspected and documented as requested by customers.

With our partnership, expect aerospace parts crafted with care, accuracy, and compliance. We uphold strict quality controls to guarantee your project’s seamless progression.

Aerospace Materials We Machine

Advanced materials balancing strength, corrosion resistance, weight, and heat tolerance are essential in aerospace parts. Roberson Machine Company works extensively with these metals and alloys, providing accurate, clean machining on even the most challenging aerospace substrates.

- Aluminum (6061, 7075, 7050): Known for being lightweight and corrosion-resistant, aluminum is ideal for housings, brackets, airframe parts, and structural assemblies. We use precise aluminum CNC machining techniques to deliver high-quality aerospace components.

- Titanium (Grades 2, 5 / 6Al-4V): Valued for its combination of high strength, low weight, and corrosion resistance, titanium is essential for aerospace fasteners, brackets, and hardware. Our titanium CNC machining capabilities ensure precision manufacturing of critical aerospace parts.

- Stainless Steel (17-4PH, 15-5PH, 303, 316, 321): Renowned for its strength, corrosion resistance, and toughness, stainless steel is common in flight controls, engine parts, and high-stress aerospace assemblies. Learn more about stainless steel grades here.

- Nickel Alloys & Superalloys (Inconel, Hastelloy, Monel): Commonly found in turbine and propulsion systems, these materials are built for extreme environments. Our CNC machining services ensure precision and excellent surface quality on nickel alloys.

- Tool Steels & Hardened Alloys (D2, A2, H13): Our EDM and CNC machining capabilities produce tooling, molds, and wear-resistant components used throughout aerospace manufacturing. We provide burr-free, complex cuts on hardened aerospace materials via wire EDM machining. Explore details on D2, A2, and H13.

- High-Performance Plastics (PEEK, Ultem, PTFE): Lightweight and resistant to chemicals, these materials are perfect for aerospace insulation, seals, electrical components, and specialty hardware. We employ advanced CNC machining capabilities to produce clean, precise parts from these plastics.

Don’t see your material here? Get in touch with your project details, and we’ll evaluate your machining requirements.

Why Salisbury, MD, Aerospace Companies Work With Roberson Machine Company

Every aerospace machining job we run for Salisbury, MD, manufacturers is built around controlling variation. From programming and fixturing to in-process inspections, we use repeatable setups and documented processes to keep parts consistent — whether it’s a one-off prototype or full production run. Dimensional accuracy, material traceability, and part consistency stay locked in at every stage.

Our documented quality procedures encompass part verification, dimensional accuracy checks, and material traceability throughout manufacturing. We offer in-process and first article inspections, alongside CMM (coordinate measuring machine) reports, and provide comprehensive documentation for aerospace programs with enhanced compliance demands.

What Sets Roberson Apart for Salisbury, MD, Aerospace Manufacturing

- Quality: We ensure every component adheres to your tolerance specifications and uses only materials approved for aerospace use.

- Reliability: Our commitment is to timely shipments, clear communication, and avoiding delays that impact your production.

- Precision: We guarantee machining precision and repeatability, starting with first article inspections and continuing through production.

For over 20 years, we’ve supported aerospace manufacturers nationwide with precision CNC parts for flight-critical applications. Leveraging advanced multi-axis machining and skilled machinists, we handle everything from prototypes to large production runs, for simple or complex parts.

Other services Roberson Machine Company provides includes:

- CNC Lathe Machining

- Custom CNC Machining for Part Production

- CNC Machine Automation

- Oil and Gas Precision Machining

- Automotive Part Manufacturing

- EDM Machining

- High Volume CNC Machining

- Industrial Automation

- Solar Panel Manufacturers

In Salisbury, MD, besides aerospace manufacturing, we deliver precise machining solutions for defense, medical, automotive, and food and beverage, applying the same detailed focus.

To discuss your Salisbury, MD, Aerospace Manufacturing needs and request a quote, contact us online or call 573-646-3996.