Plastic parts manufacturer Raleigh, NC. The significance of plastic parts in the manufacturing landscape, especially at an industry leader like Roberson Machine Company, cannot be overstated. Catering to a myriad of industries in Raleigh, NC and across the country, ranging from automotive to consumer goods, the demand for top-notch plastic components remains consistently high.

Selecting the ideal plastic parts manufacturer is a pivotal decision that directly impacts your product’s performance, resilience, and overall success. Welcome to Roberson Machine Company, a distinguished national manufacturer of plastic parts headquartered in the heart of the Midwest. Our capabilities are diverse, our pricing is competitive, our customer care is exemplary, and our turnaround times are swift for your Raleigh, NC company.

Give us a call as soon as possible at 573-646-3996 or contact us online to get a quote. We get you the parts you want, on time in Raleigh, NC, and at or above your expectations.

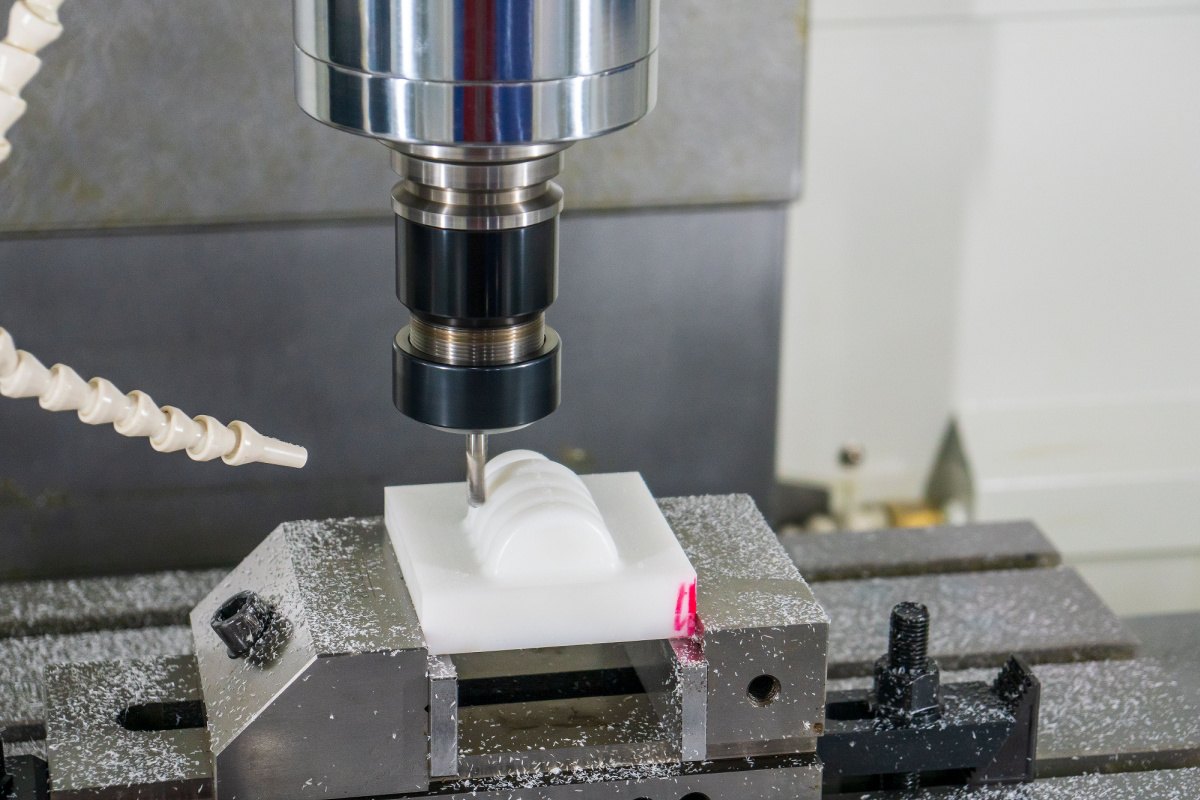

Plastic Parts Manufacturer For Your Company in Raleigh, NC: CNC Machining at Roberson Machine Company

We use our CNC turning and CNC milling machines for manufacturing plastic parts because of the ability to produce uniform and precise components with incredibly tight tolerances, no matter if your Raleigh, NC project calls for a small or large production run.

Manufacturing plastic parts with CNC machining – which saves us time and cuts down on human errors due to our automation – allows us to pass along the savings to you. We are committed to excellence in everything we do and we hope to partner with you on your next plastic parts project, and more.

Raleigh, NC Plastic Parts Manufacturer: Top Benefits to Partnering With a Pro Like Roberson Machine Company

The decision to partner with a dependable plastic parts manufacturer, like Roberson Machine Company, involves careful consideration of key factors and offers a multitude of benefits. Here’s an overview of the vital aspects and benefits:

- Material Selection & Customization

The choice of materials significantly influences the performance and longevity of plastic parts. We offer a comprehensive range of materials, each tailored to specific environmental conditions and applications. Our skilled machinists are readily available to offer detailed insights into the various types of plastics we use for our clients. Give us a call at 573-646-3996 or reach out to us online. Examples of the types of plastics we frequently use include:

- Delrin (Polyoxymethylene, POM): Probably the most machined of all plastics, we suggest POM to customers who need a high-strength plastic with exceptional resistance to wear, weather, fuel, and chemicals. Perhaps the only downside to this plastic is that it has poor resistance to acidic elements.

- Acrylic (PMMA): A rigid thermoplastic known for its optical clarity, acrylic is suitable for industries where transparency is crucial.

- Acrylonitrile Butadiene Styrene (ABS): ABS is a versatile thermoplastic celebrated for its impact resistance, strength, and toughness, making it ideal for a wide range of applications.

- Nylon (Polyamide, PA): Nylon is strong, durable, and resistant to abrasion.

- Polyethylene (PE): A lightweight and chemically resistant plastic.

- Polyetheretherketone (PEEK): Known for its resistance to liquids, chemicals, fatigue, wear, and temperatures up to 480°, PEEK is often suggested to customers as a replacement to metal.

- Polypropylene (PP): Commonly used plastic that is cost–effective, versatile, and chemically resistant.

- Polytetrafluoroethylene (PTFE): Commonly known as Teflon, PTFE is valuable to customers looking for commercial products or parts.

- Polyvinyl Chloride (PVC): PVC is an ideal choice for industrial applications requiring corrosion resistance and insulation properties.

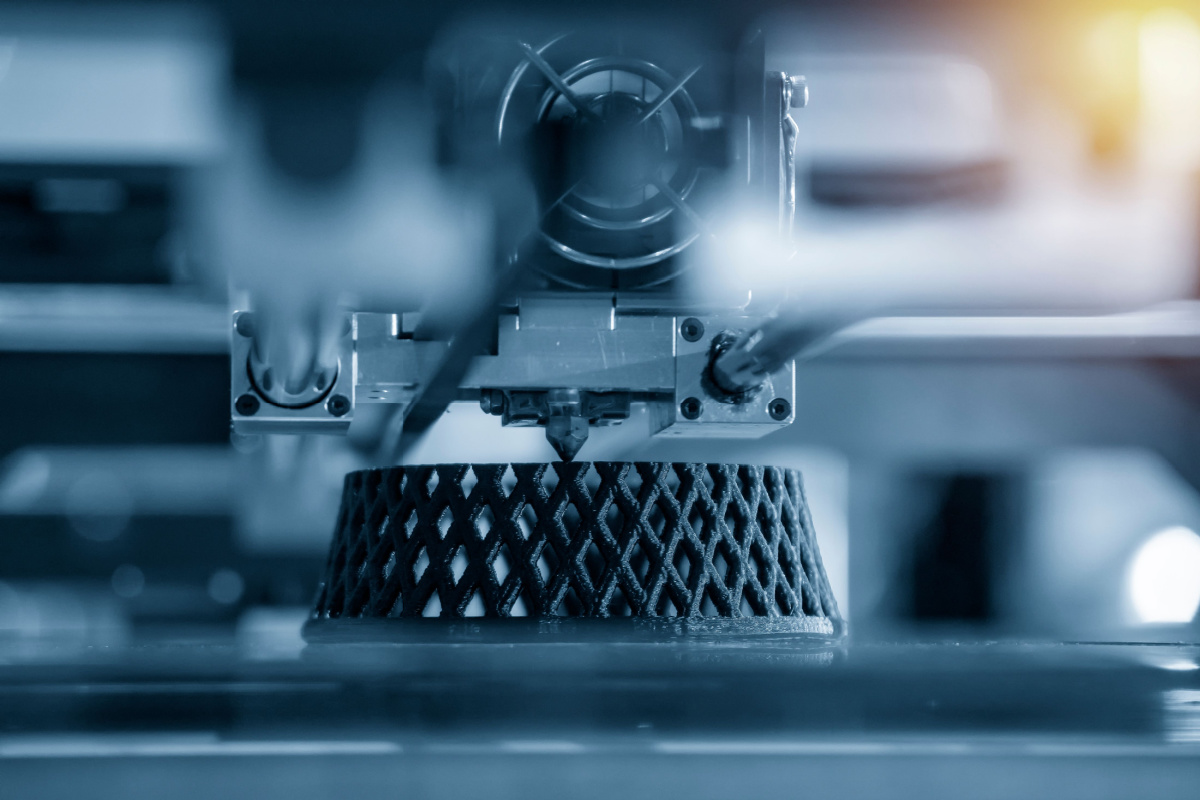

- Advanced Technology & Equipment

State-of-the-art technology and cutting-edge equipment are indicative of our commitment to precision and efficiency. As a reputable plastic parts manufacturer, we invest in modern machinery and production processes, making sure we stay at the forefront of industry advancements. Along with our CNC turning and CNC milling machines, our facility boasts the following advanced capabilities:

- Wire EDM

- 5 Axis Machining

- Multi Axis Machining

- Aluminum CNC Machining

- Stainless Steel Machining

- Value Added Services

- Scalability & Timely Delivery

The ability of a leading plastic parts manufacturer to scale production according to your needs is crucial for both small-scale projects and large-scale manufacturing. Equally important is the timely delivery of your parts to meet project timelines and market demands. We pride ourselves on our adaptability, capable of manufacturing 10 or 10,000 plastic parts. Situated centrally in our own facilities and on our own land, we ensure fast delivery with easy access to major markets near you in Raleigh. This ensures that your plastic parts are on schedule, avoiding any disruptions in your supply chain.

- Expertise & Experience

Selecting a plastic parts manufacturer with a proven track record and extensive experience is paramount. We bring a wealth of knowledge to the table, allowing us to navigate complex design challenges, material specifications, and production intricacies. With a diverse portfolio that showcases our proficiency in producing a wide array of plastic parts, including the following examples, we bring unparalleled expertise to every project:

Plastic Parts Manufacturer For Your Company in Raleigh, NC: Project Showcase

Our company combines the agility to deliver customized capabilities and personalized services with the scale to seamlessly handle substantial production runs within demanding timelines – all while upholding the highest standards of quality and customer care. To explore how we can tailor our services to meet your Raleigh, NC project’s unique needs, take advantage of a free project consultation. Don’t hesitate to call 573-646-3996 or contact us online to get a quote tailored to your project specifications in Raleigh, NC:

In addition to being a leading plastic parts manufacturer in Raleigh, NC and across the country, Roberson Machine Company provides the following for Raleigh, NC clients:

- Oil and Gas Precision Machining

- Aerospace Manufacturing

- Automotive Part Manufacturing

- EDM Machining

- High Volume CNC Machining

- Industrial Automation

- Solar Panel Manufacturers

- Microscope Parts Precision Machining

- Military Manufacturing

- Medical Brace Manufacturing

Raleigh, NC Plastic Parts Manufacturer: A Reliable Partner You Can Trust

Quality assurance is non-negotiable in our machine shop. We adhere to our stringent internal quality control standards in order to maintain consistent quality throughout the production process. Our Raleigh, NC clients count on us to deliver precision machined parts with exceptional customer care, accuracy, and at competitive pricing. This dedication to quality and consistency is evident in our partnerships in Raleigh, NC and across the country, and our overall customer satisfaction. We refuse to let our clients down.

We realize that what was effective in the past may not necessarily be suitable for the present. As such, we continually adapt, not only in terms of our machinery but also our manufacturing solutions, to not just meet but exceed your expectations in Raleigh, NC and industry benchmarks.

Reach Out to a Leading Raleigh, NC Plastic Parts Manufacturer Right Away at Roberson Machine Company

Choosing the right plastic parts manufacturer for your company in Raleigh, NC is a strategic decision that influences the success of your products in the market. By prioritizing our technological advancement, material customization, expertise, and quality assurance, you can forge a partnership with a manufacturer that not only meets but exceeds your expectations. Elevate your Raleigh, NC company’s projects by aligning with a trusted plastic parts manufacturer like Roberson Machine Company.

Call us now at 573-646-3996 or contact us online to get started on your next plastic parts project in Raleigh, NC.