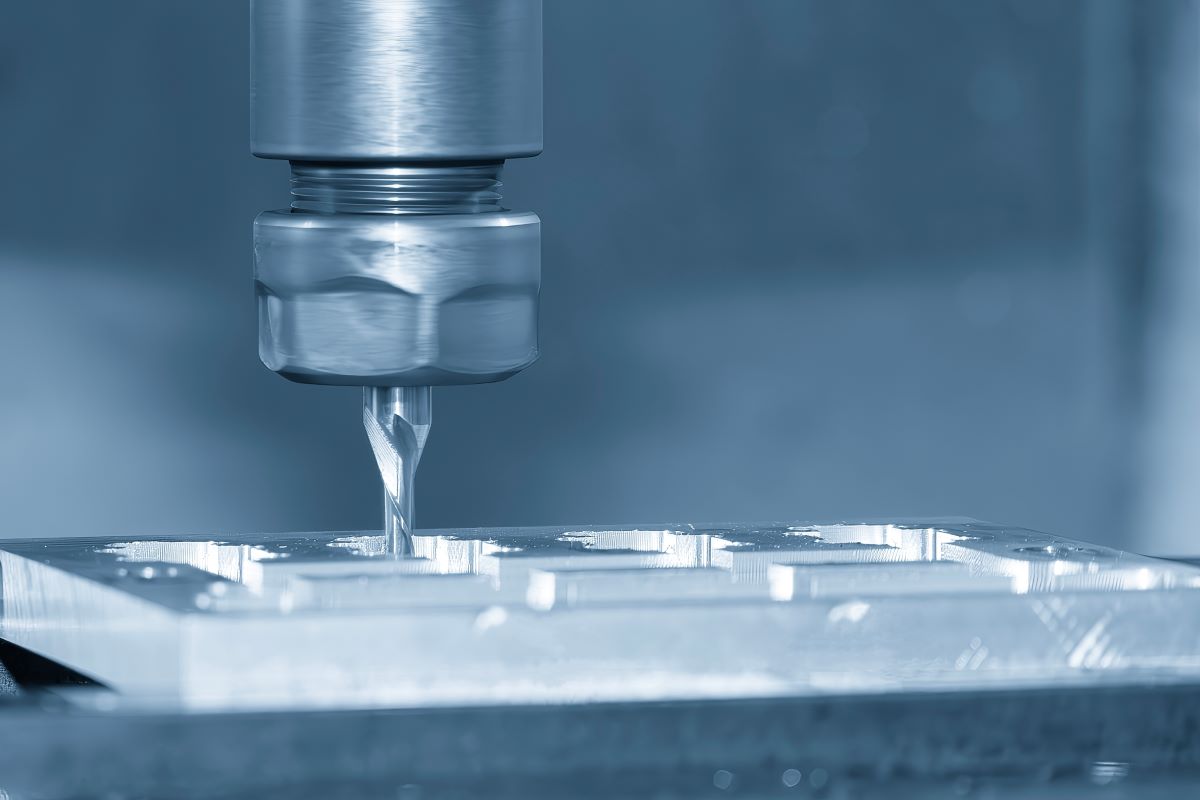

CNC milling aluminum Chattanooga, TN. In our manufacturing realm, precision and efficiency are non-negotiables at Roberson Machine Company. As industries evolve, so do the machining methodologies and technologies employed to fabricate parts with swiftness and exactitude. CNC milling aluminum stands as a foundational method in our machine shop, and should be an optimal option for your Chattanooga, TN company’s component needs.

If your project in Chattanooga, TN requires intricate part dimensions, our expertise in both multi axis and 5 axis machining ensures precise production tailored to your specifications. With our state-of-the-art CNC mills, we excel at getting exceptional precision, handling tasks of varying complexity with ease, regardless of the size of the production run.

Give the Roberson Machine Company experts a call right now at 573-646-3996 or connect with us online for more information about CNC milling aluminum or to get a quote for your company’s next project in Chattanooga, TN.

CNC Milling Aluminum: Unlocking Precision & Efficiency For Your Company in Chattanooga, TN

Few materials come close to the remarkable versatility of aluminum. Prized for its pliability, lightweight nature, and impressive strength-to-weight ratio – nearly double that of steel – aluminum is highly machinable, making it ideal for CNC milling.

Given the advancements in our industry – including a greater emphasis on fuel efficiency and automation – aluminum has frequently replaced heavier metals traditionally machined to make heavier components and internal structures. Aluminum is also the most abundant and cheapest metal on the planet and is 100 percent recyclable. Also, unlike other metals, it retains all of its original properties. An estimated 75% percent of all aluminum produced is still in use today.

Why CNC Milling Aluminum?

Regardless of the method used or the temperatures reached, aluminum parts machined at Roberson Machine Company retain their primary properties. Call us today at 573-646-3996 or reach out to connect with us online. Other notable advantages provided by our CNC milling aluminum service encompass:

- Precision Machining: Our specialists harness CAD and CAM software to meticulously program the movements and dimensions of our CNC milling machines, enabling the creation of and precise tolerances on each part. This level of precision is crucial for machining complex aluminum components with utmost accuracy and uniformity.

- Speed & Efficiency: CNC milling aluminum enhances manufacturing efficiency by automating repetitive tasks and minimizing errors, thereby reducing overall production time. With optimized toolpaths and high-speed machining capabilities, CNC milling ensures swift material removal and expedited turnaround times for your Chattanooga, TN company’s parts.

- Versatility: CNC milling offers unparalleled versatility to cater to a wide range of manufacturing requirements, whether it entails machining extensive production batches or intricate, small-scale parts. From rudimentary prototypes to complex components, CNC milling aluminum can accommodate a wide array of shapes, sizes, and part designs.

- Affordability: CNC milling aluminum with us minimizes material waste, reduces labor costs, and enhances overall productivity, making it a cost-effective option for both large and small production runs.

Roberson Machine Company Optimizes CNC Milling Aluminum For Your Parts in Chattanooga, TN

To harness the full potential of CNC milling aluminum for your Chattanooga, TN company, we prioritize key factors of our machining process:

Material Selection

We collaborate closely with you to select the ideal grade of aluminum tailored to the specific requirements of your application, considering factors like corrosion resistance, strength, and machinability. Some of the grades of aluminum we use include:

- 6061 – Probably the most popular aluminum alloy, along with 7075. It has excellent machinability characteristics and can be easily welded. This alloy is often used to make electrical fittings, brake pistons, and bike frames.

- 7075 – Noted for its exceptional strength, 7075 is among the strongest aluminum alloys available. This grade achieves its strength by sacrificing corrosion resistance, making it ideally suited for aircraft wings and fuselages, meter shafts and gears, and shaft keys.

- 2024 – Widely utilized in the aerospace and military sectors, 2024 offers impressive mechanical properties, including high fatigue resistance, strength, and resistance to thermal shocks.

- 5052 – This alloy is extremely resistant to corrosion, due to the lack of copper in its composition, but it can’t be heat treated. It is commonly used in fuel tanks, sheet metal parts, and fuel/oil lines.

- 7050 or “aa7050 alloy” – This alloy offers a combination of high strength and high resistance to corrosion. It is commonly used in aerospace structures like fuselage frames and wing components.

Partner with us to explore the diverse range of aluminum alloys and discover the perfect fit for your machining needs. Give us a call now at 573-646-3996 or reach out to us online.

Quality Assurance

Throughout the milling process, we uphold stringent internal quality control standards to guarantee precise dimensional accuracy, surface finish, and compliance with your Chattanooga, TN company’s design specifications.

Tooling & Machining Parameters

We meticulously fine-tune tool selection, cutting speeds, feeds, and toolpaths to achieve maximum efficiency and superior surface finish. By mitigating machining vibrations and minimizing tool wear, we not only uphold quality standards but also pass on cost savings to you.

Dedication to Continous Improvement

We are constantly looking for ways to embrace innovation and improvement initiatives to enhance our manufacturing processes and methods, reduce lead times, optimize overall efficiency in our CNC milling aluminum operations.

In addition to being the CNC milling aluminum leader for businesses in Chattanooga, TN and across the country, Roberson Machine Company provides the following for clients throughout the Chattanooga, TN area:

- Aerospace Manufacturing

- Automotive Part Manufacturing

- EDM Machining

- High Volume CNC Machining

- Industrial Automation

- Solar Panel Manufacturers

- Microscope Parts Precision Machining

- Military Manufacturing

- Medical Brace Manufacturing

Reach Out to the Chattanooga, TN CNC Milling Aluminum Experts at Roberson Machine Company Now

We have more than 20 years of experience in CNC milling aluminum, along with our other leading manufacturing services. Our well-equipped machine shop is centrally located for fast delivery times and access to major markets near Chattanooga, TN.

Give us a call right away at 573-646-3996 or contact us online to get a quote for your Chattanooga, TN company’s next production run.