Corpus Christi, TX, CNC Machine Automation combines advanced CNC machining, robotics, and smart processes to deliver CNC Machine Automation for industries that require precision, demand efficiency, and operate under strict quality standards.

We pair these systems with automation-ready machining for repeatable results across full production runs. Backed by 20+ years of experience, our U.S.-based team supports your projects with precision CNC machining while controlling costs through efficient automation. CNC Machine Automation in Corpus Christi, TX, scales output without sacrificing accuracy—contact us online or call 573-646-3996.

Article Summary | CNC Machine Automation in Corpus Christi, TX

- What CNC machine automation is and how it extends traditional machining

- Improvements to output, quality consistency, lower costs, and the ability to scale

- High-repeat parts commonly produced with automated machining

- Use cases and sectors where CNC automation drives the biggest gains

Machine automation gives Corpus Christi, TX, manufacturers the ability to scale production without losing accuracy or repeatability. It transforms one-off processes into predictable workflows to make sure high-volume output meets standards without adding overhead.

Table of Contents

- What Is CNC Machine Automation?

- Common CNC Parts for Automation

- Advantages of CNC Machine Automation

- Industries We Support

- Frequently Asked Questions

- Why Choose Roberson Machine Company?

To see CNC automation in practice, explore our reviews, the latest case studies, and more insights on our blogs and FAQs.

What Is CNC Machine Automation?

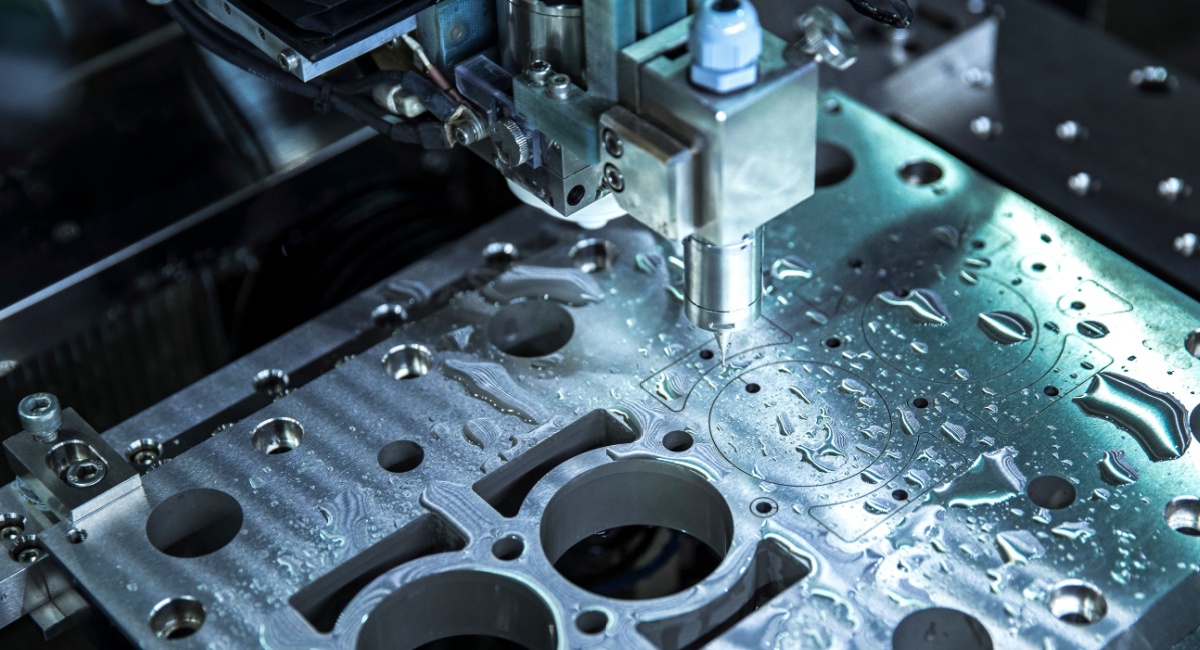

Corpus Christi, TX, CNC machine automation combines robotics, probing, pallet changers, and smart manufacturing with established machining workflows. Automation minimizes touchpoints, extends run time, and stabilizes results.

- Uses robotics and pallet changers to handle parts automatically

- Reduces operator involvement in setups and measurements

- Keeps machines running longer with fewer stoppages

- Delivers consistent, repeatable quality across production runs

Manual setups remain relevant. They’re practical for prototypes, one-off jobs, and highly customized parts where direct oversight makes sense. But when production scales, the difference between manual and automated CNC machining becomes clear. Automated workflows rely on robotics, probing, and preprogrammed routines to skip repetitive steps, minimize stoppages, and keep quality uniform—even in lights-out manufacturing runs.

Common Parts for CNC Automation in Corpus Christi, TX

Automation powers efficient production of repeatable components across sectors. Here are core components commonly made with CNC machine automation to lift quality and minimize waste:

- Gears and drive shafts

- Brackets and housings

- Medical instruments

- Conveyor rollers

- Fixtures

- Valve bodies

- Pump housings

- Actuator parts

- Tooling inserts

- Couplings and connectors

- Packaging rollers

- Hydraulic manifolds

- Heat exchanger plates

- Robotic end effectors

These components align well with CNC machine automation, where consistent, repeatable specs carry through long production runs. Contact us to minimize downtime and meet your build goals.

Advantages of Corpus Christi, TX, CNC Machine Automation

CNC automation reaches past machine time; it raises throughput, steadies quality, and enables scaling without more overhead. Key benefits include:

Productivity and Throughput

Shorter changeovers and lights-out runs add cutting hours and push more parts out the door.

Consistency and Quality

Automated probing teams with tool monitoring and robotic handling to maintain tolerances and reduce rework. Quality control moves upstream—into the process itself.

Efficiency and Cost Savings

Lower scrap, faster setups, and reduced labor keep projects lean. Even small gains in scrap reduction add up to thousands at volume. Automation also helps with OSHA compliance by cutting manual touchpoints.

Scalability

From prototypes to mass production, automated workflows adapt without costly resets. The same setup can validate a design and then deliver full runs with predictable quality.

From finishing and inspection to assembly, our value-added services support automation workflows, underscoring CNC machine automation as a foundation of today’s manufacturing.

Industries We Support

Corpus Christi, TX, CNC machine automation creates measurable value across sectors where precision and consistency matter. At Roberson Machine Company, we apply advanced CNC machining technology to support industries including:

- Aerospace

- Automotive & Heavy Machinery

- Medical & Pharmaceutical

- Food & Beverage

- Oil & Energy

- Other Industries

This includes Corpus Christi, TX, CNC machine automation options for everything from turbine components and surgical instruments to conveyor rollers and automotive drive shafts. Wherever precision, durability, and repeatability matter, automation makes production more reliable and cost-effective.

Frequently Asked Questions

What is CNC machine automation?

Using robotics with probing, pallet changers, and monitoring systems to keep equipment cutting longer with fewer stops.

Which parts are best for automation?

Volume parts such as gears, housings, fixtures, rollers, and valve bodies that rely on consistent dimensions and repeatable process control.

Can it handle prototypes as well as production?

Yes. Start with pilot lots to validate the workflow, then expand to full-rate production without rebuilding the process.

Can you run lights-out (unattended) production?

Robotics and pallet systems, paired with tool-life monitoring, keep work moving after hours so jobs run through the night or weekend with minimal oversight.

How does quality control fit in?

In-machine probing and tool monitoring pair with CMM verification to maintain tolerances from first article through last-off.

Does automation reduce lead times?

With fewer manual setups and lights-out operation, automation cuts lead time and helps projects meet deadlines.

Is CNC automation cost-effective for small runs?

Yes. With probing and rapid changeovers, the same cell switches parts quickly, making low-quantity orders cost-competitive.

What industries benefit most?

Aerospace, automotive, medical, and energy lean on automation for precise, high-volume production within compliance, while most industries benefit from steady, repeatable quality.

Why Choose Roberson Machine Company for Corpus Christi, TX, CNC Machine Automation?

Partnering with Roberson Machine Company means more than advanced cells: documented processes, flexible scheduling, and a team dedicated to meeting timelines and specifications. This includes:

- U.S.-based facility with modern CNC machining centers and wire EDM equipment

- Right-sized production capacity for prototypes, small lots, and full automation runs

- Value-added services that support complete project workflows

- Cost-competitive rates and predictable lead times

Our team delivers end-to-end Corpus Christi, TX, CNC services that support automation projects:

- Custom CNC Machining for Part Production

- Oil and Gas Precision Machining

- Aerospace Manufacturing

- Automotive Part Manufacturing

- EDM Machining

- High Volume CNC Machining

- Industrial Automation

- Solar Panel Manufacturers

- Microscope Parts Precision Machining

Roberson Machine Company equips manufacturers with CNC automation engineered for accuracy, efficiency, and scale. Learn more at our team and capabilities, request a quote online, or call 573-646-3996 to leverage Corpus Christi, TX, CNC Machine Automation on your floor.