Durable materials make durable parts. Metals, plastics, wood, and foam can be used in a variety of applications and industries, but it can get a bit overwhelming when looking at all the different types and options within each category.

Some of the most common materials used, their benefits, and applications/industries used are listed below. Please contact our team at 573-646-3996 if you have any questions or request a quote today!

Aluminum

Probably one of the most widely used CNC machining materials, aluminum is a great option for both aspect and mechanical components. When exposed to the environment, parts made using aluminum form a protective layer, which leads to extra strength and corrosion resistance. Because this material is machined quicker than others, it may be the most economically viable option.

- Benefits: Improved corrosion resistance, good formability and weldability, able to be machined quicker than others, economically-priced.

- Applications/industries used: automotive, aerospace, healthcare, aircraft fittings, medical devices, gears and shafts, etc.

Alloy Steel

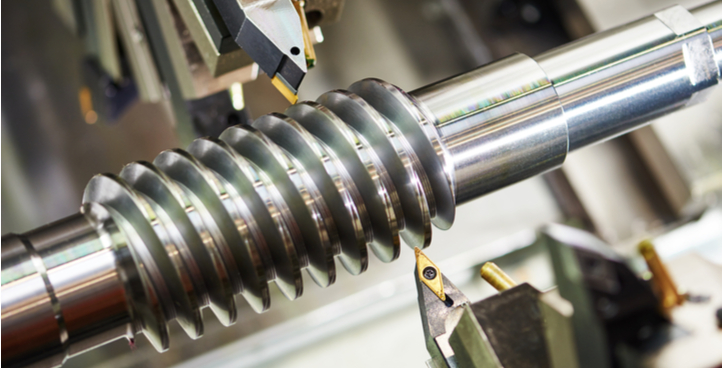

Engineered for excellent machinability, alloy steel is typically used for parts that require stronger welds and enhanced formability. Depending on the alloy of the steel (the most common of which include 1215, 1018, etc), it is a great option for parts that require strong welds, gears and shafts, along with other high stress applications.For example, energy companies use alloy steel parts of a consistent basis in applications that require excellent strength and corrosion resistant properties.

- Benefits: High strength, heat treatable, enhanced formability.

- Applications/industries used: automotive, aerospace, etc.

Low Carbon Steel

Carbon steel is easy to machine and used for applications that require high strength.

However, as a magnetic material, it rusts easily when exposed to certain environmental conditions.

- Benefits: Good formability and weldability, excellent machinability.

- Applications/industries used: Rivets and parts requiring strong welds, gears, shafts, studs, higher stress applications, etc.

Stainless Steel

Stainless steel is a great option used for anything from electronic hardware to medical devices, as well as other parts that require more weldability and formability. As a strong material, stainless steel is nonmagnetic and corrosion resistant. Most of the grades of stainless steel are ideal for outdoor applications and provide excellent strength.

- Benefits: Better weldability and formability, increased resistance to cracking, pitting, and corrosion.

- Applications/industries used: Medical, aerospace, applications needing corrosion resistance and hardness, household applications such as food-handling equipment, machinery parts, screws, car headers, etc.

Brass

As a nonmagnetic material, brass is commonly used for creating components that require strength applications and electrical conductivity. Brass parts increase visual appeal while also providing considerable strength. It is recognized as one of the easiest and cost-effective materials to use with CNC machining.

- Benefits: low friction coefficient, high corrosion resistant properties, Good corrosion resistance, resistant to most chemicals.

- Applications/industries used: medical equipment, consumer goods, and electrical hardware and contacts, engineering, plumbing, steam work, musical instruments, etc.

Plastics

There are numerous choices when it comes to plastics including PVC, Acetal (POM), Acrylics (PMMA), Nylon, Polycarbonate (PC) and Polypropylene (PP), and more. Many of these plastics are easily machinable and are utilized for applications that require corrosion resistance, weight, transparency, and less friction.

- Benefits: cost-effective, good flame resistance, dimensional stability, impact strength.

- Applications/industries used: insulators, bearings, bushings, electrical insulation, aerospace, automotive, medical, electronics, etc.