Sacramento, CA, CNC Machine Automation integrates CNC machining with robotics and automated part handling to deliver CNC Machine Automation for organizations prioritizing precision, throughput, and quality control.

These systems run with automation-ready machining to keep repeatable results across full production runs. Backed by 20+ years, our U.S.-based team delivers precision CNC machining and trims costs through automation. In Sacramento, CA, CNC Machine Automation scales output while holding spec—contact us online or call 573-646-3996.

Article Summary | CNC Machine Automation in Sacramento, CA

- Definition of CNC machine automation and how it augments traditional machining

- Gains in throughput, repeatability, cost reduction, and scalable capacity

- Typical components that run well in automated CNC machining

- Applications and industries where CNC automation provides the strongest value

For manufacturers in Sacramento, CA, machine automation enables scalable production while holding accuracy and repeatability; it converts one-off processes into predictable workflows so high-volume results stay within spec without extra overhead.

Table of Contents

- What Is CNC Machine Automation?

- Common CNC Parts for Automation

- Advantages of CNC Machine Automation

- Industries We Support

- Frequently Asked Questions

- Why Choose Roberson Machine Company?

For real-world examples of CNC automation, check our reviews, recent case studies, plus additional insights on our blogs and FAQs.

What Is CNC Machine Automation?

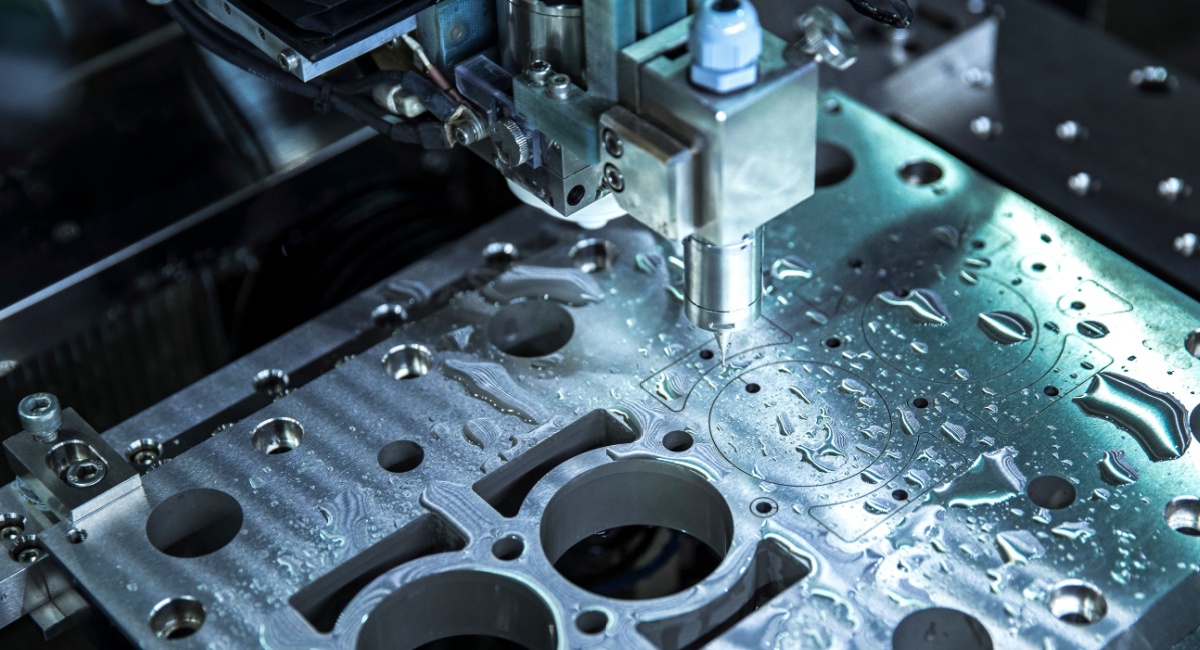

Sacramento, CA, CNC machine automation builds on traditional machining with robotics, in-machine probing, pallet changers, and smart manufacturing systems. Rather than operator input at every step, automation keeps equipment running longer with fewer interruptions and more consistent results.

- Uses robotics and pallet changers to handle parts automatically

- Reduces operator involvement in setups and measurements

- Keeps machines running longer with fewer stoppages

- Delivers consistent, repeatable quality across production runs

Manual setups still have a place. They suit prototypes, unique jobs, and custom parts that call for direct supervision. But when production scales, the difference between manual and automated CNC machining becomes clear. Automated workflows apply robotics, probing, and scripted routines to streamline repeat tasks, cut stoppages, and maintain consistent quality—even in lights-out manufacturing runs.

Common Parts for CNC Automation in Sacramento, CA

Automation powers efficient production of repeatable components across sectors. Here are core components commonly made with CNC machine automation to lift quality and minimize waste:

- Gears and drive shafts

- Brackets and housings

- Medical instruments

- Conveyor rollers

- Fixtures

- Valve bodies

- Pump housings

- Actuator parts

- Tooling inserts

- Couplings and connectors

- Packaging rollers

- Hydraulic manifolds

- Heat exchanger plates

- Robotic end effectors

When accuracy and repeatability have to hold across hundreds or thousands of pieces, parts like these belong in CNC machine automation. Contact us to reduce stoppages and stay on target.

Advantages of Sacramento, CA, CNC Machine Automation

CNC automation does more than keep machines running. It drives productivity, delivers consistent results, and helps manufacturers scale without adding overhead. Key benefits include:

Productivity and Throughput

Shorter changeovers and lights-out runs add cutting hours and push more parts out the door.

Consistency and Quality

Probing, tool monitoring, and robotic handling work together to stabilize tolerances and limit rework. Quality control becomes continuous, not a final step.

Efficiency and Cost Savings

Less scrap, fewer setups, and lower labor needs keep projects lean. Even a small percentage of scrap reduction can save thousands in high-volume runs. Automation also supports OSHA compliance by reducing manual touchpoints.

Scalability

Automated workflows adapt from prototypes to mass production without costly resets; one setup validates the design and then runs full production with predictable quality.

Our value-added services—finishing, inspection, assembly—support automation at every stage, reinforcing CNC machine automation as a modern manufacturing standard.

Industries We Support

Sacramento, CA, CNC machine automation creates measurable value across sectors where precision and consistency matter. At Roberson Machine Company, we apply advanced CNC machining technology to support industries including:

- Aerospace

- Automotive & Heavy Machinery

- Medical & Pharmaceutical

- Food & Beverage

- Oil & Energy

- Other Industries

These Sacramento, CA, CNC machine automation options cover everything from surgical instruments and turbine components to conveyor rollers and automotive drive shafts. Wherever precision, durability, and repeatability matter, automation makes production more reliable and cost-effective.

Frequently Asked Questions

What is CNC machine automation?

The integration of robotics, probing, pallet changers, and monitoring systems that keep machines running longer with fewer interruptions.

Which parts are best for automation?

Common candidates include gears, machined housings, workholding fixtures, conveyor rollers, and valve bodies—components built to the same spec each run.

Can it handle prototypes as well as production?

Yes. Automated setups can run small prototype batches and then scale into full production without major changes to the process.

Can you run lights-out (unattended) production?

Robots, pallet-changing systems, and tool-life monitoring enable unattended overnight and weekend runs with only periodic checks.

How does quality control fit in?

Probing inside the machine, combined with tool monitoring and downstream CMM checks, keeps dimensions on target across the entire run.

Does automation reduce lead times?

Minimizing setups and extending run time into nights and weekends shortens turnaround and supports on-time delivery.

Is CNC automation cost-effective for small runs?

Often, yes. In-process probing and modular fixturing shorten changeovers on short runs, spreading setup time over fewer parts.

What industries benefit most?

From aerospace and automotive to medical and energy, automation supports precision work at scale, and most other sectors see value in consistent, repeatable output.

Why Choose Roberson Machine Company for Sacramento, CA, CNC Machine Automation?

Partnering with Roberson Machine Company means more than advanced cells: documented processes, flexible scheduling, and a team dedicated to meeting timelines and specifications. This includes:

- U.S.-based facility with modern CNC machining centers and wire EDM equipment

- Capacity that scales from pilot lots to high-volume automated production

- Value-added services for end-to-end project workflows

- Competitive pricing with dependable lead times

We also provide a full range of Sacramento, CA, CNC services to support automation projects:

- Precision Stainless Steel Machining

- CNC Lathe Machining

- Custom CNC Machining for Part Production

- Oil and Gas Precision Machining

- Aerospace Manufacturing

- Automotive Part Manufacturing

- EDM Machining

- High Volume CNC Machining

- Industrial Automation

Roberson Machine Company delivers CNC automation solutions built for accuracy, efficiency, and scale. Learn more about our team and capabilities, request a quote online, or call 573-646-3996 to see how Sacramento, CA, CNC Machine Automation can keep your production running smoothly.