New Orleans, LA, CNC Machine Automation pairs advanced CNC machining with robotics and in-process monitoring to deliver CNC Machine Automation for manufacturers focused on precision, efficiency, and compliant production.

We align these systems with automation-ready machining to maintain repeatable results across full runs. Supported by 20+ years of experience, our U.S.-based team advances your projects with precision CNC machining and cost-efficient automation. In New Orleans, LA, CNC Machine Automation boosts output without compromising accuracy—contact us online or call 573-646-3996.

Article Summary | CNC Machine Automation in New Orleans, LA

- What CNC machine automation is and how it advances conventional machining

- Key benefits: higher throughput, steadier quality, lower costs, and easier scaling

- Repeatable components ideal for CNC automation

- Use cases and sectors where CNC automation drives the biggest gains

In New Orleans, LA, machine automation expands production capacity without trade-offs in accuracy or repeatability; it replaces ad hoc steps with predictable workflows so high-volume runs meet spec without increasing overhead.

Table of Contents

- What Is CNC Machine Automation?

- Common CNC Parts for Automation

- Advantages of CNC Machine Automation

- Industries We Support

- Frequently Asked Questions

- Why Choose Roberson Machine Company?

For real-world examples of CNC automation in action, see our reviews, recent case studies, and other insights on our blogs and FAQs.

What Is CNC Machine Automation?

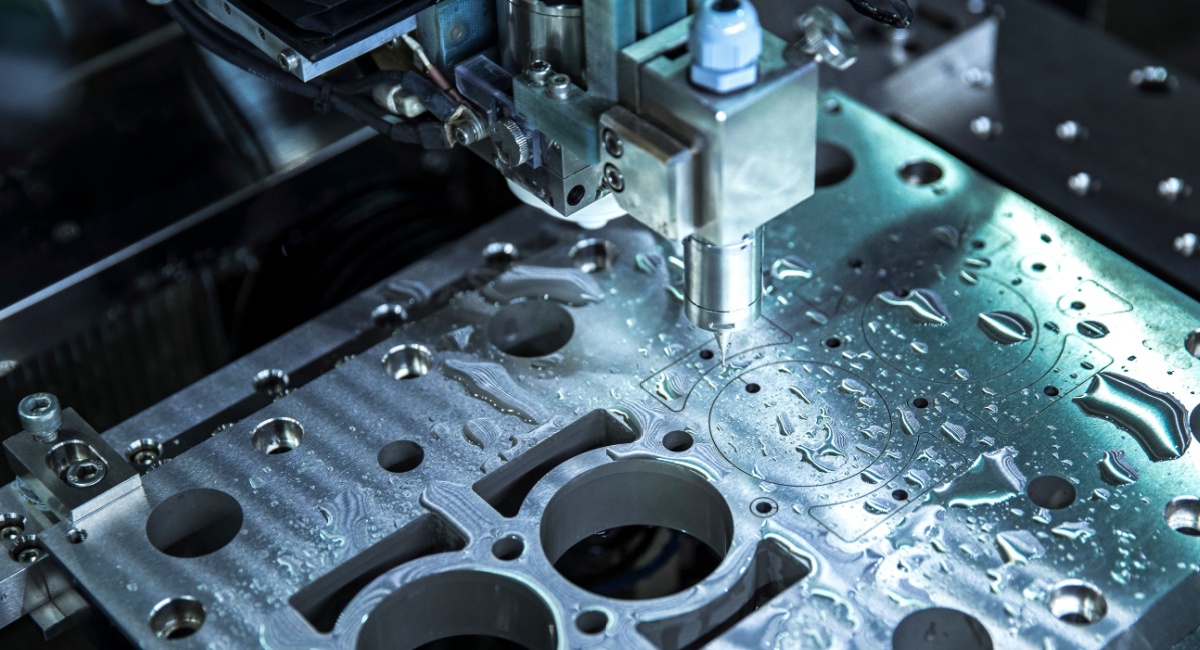

In New Orleans, LA, CNC machine automation augments traditional machining using robotics, probing, pallet changers, and smart manufacturing systems. By reducing step-by-step operator input, it runs longer with fewer interruptions and steadier results.

- Uses robotics and pallet changers to handle parts automatically

- Reduces operator involvement in setups and measurements

- Keeps machines running longer with fewer stoppages

- Delivers consistent, repeatable quality across production runs

Manual setups remain useful. They fit prototypes, short-run jobs, and custom parts where hands-on control matters. But when production scales, the difference between manual and automated CNC machining becomes clear. Automated workflows use robotics, in-machine probing, and programmed routines to remove repetitive steps, reduce stoppages, and keep quality consistent—even in lights-out manufacturing runs.

Common Parts for CNC Automation in New Orleans, LA

Automation optimizes production of repeatable components found across the industrial landscape. Below are core parts typically manufactured with CNC machine automation to enhance quality and reduce bottlenecks:

- Gears and drive shafts

- Brackets and housings

- Medical instruments

- Conveyor rollers

- Fixtures

- Valve bodies

- Pump housings

- Actuator parts

- Tooling inserts

- Couplings and connectors

- Packaging rollers

- Hydraulic manifolds

- Heat exchanger plates

- Robotic end effectors

These components align well with CNC machine automation, where consistent, repeatable specs carry through long production runs. Contact us to minimize downtime and meet your build goals.

Advantages of New Orleans, LA, CNC Machine Automation

CNC automation isn’t just about uptime. It lifts productivity, locks in consistency, and lets manufacturers scale without extra overhead. Key benefits include:

Productivity and Throughput

Reduced setup time and unattended runs increase spindle hours and ship more parts.

Consistency and Quality

Automated probing, tool monitoring, and robotic handling hold tolerances steady and cut rework. Quality control lives inside the process, not after it.

Efficiency and Cost Savings

Less scrap, quicker setups, and leaner labor requirements keep costs down. Even small improvements in scrap reduction save thousands at high volumes. Automation also supports OSHA compliance by reducing manual touchpoints.

Scalability

From prototype to high-volume, automated workflows adapt without expensive resets—the same setup proves the design and then delivers full runs with predictable quality.

From finishing and inspection to assembly, our value-added services support automation workflows, underscoring CNC machine automation as a foundation of today’s manufacturing.

Industries We Support

New Orleans, LA, CNC machine automation supports quality and consistency across diverse applications. At Roberson Machine Company, we bring advanced CNC machining technology to industries including:

- Aerospace

- Automotive & Heavy Machinery

- Medical & Pharmaceutical

- Food & Beverage

- Oil & Energy

- Other Industries

In New Orleans, LA, CNC machine automation options span everything from turbine components and surgical instruments to conveyor rollers and automotive drive shafts. Wherever precision, durability, and repeatability matter, automation makes production more reliable and cost-effective.

Frequently Asked Questions

What is CNC machine automation?

Robotics plus probing, pallet changing, and monitoring—built to increase uptime and minimize interruptions.

Which parts are best for automation?

Common candidates include gears, machined housings, workholding fixtures, conveyor rollers, and valve bodies—components built to the same spec each run.

Can it handle prototypes as well as production?

Yes. Automation supports prototype-to-production continuity; once validated, the workflow scales by adding pallets or shifts rather than redesigning.

Can you run lights-out (unattended) production?

Combining robotic tending, pallet-changing, and tool-life monitoring allows extended unattended operation—overnight and weekend production with brief check-ins.

How does quality control fit in?

In-machine probing and tool monitoring work alongside CMM checks to hold tolerances steady from the first part to the last.

Does automation reduce lead times?

By minimizing manual setups and keeping machines running after hours, automation shortens turnaround and helps projects hit delivery dates.

Is CNC automation cost-effective for small runs?

It can be. Automated probing and quick-change setups cut wasted time even on limited batches, keeping per-part costs under control.

What industries benefit most?

Aerospace, automotive, medical, and energy use automation to hit accuracy, throughput, and regulatory targets—yet most industries gain from consistent, repeatable parts.

Why Choose Roberson Machine Company for New Orleans, LA, CNC Machine Automation?

With Roberson Machine Company, you get more than advanced CNC automation. You gain documented processes, flexible capacity, and a team committed to keeping your projects on time and on spec. This includes:

- U.S.-based shop featuring up-to-date CNC machining centers and wire EDM capability

- Flexible production capacity, from short runs to high-volume automation projects

- Value-added services enabling turnkey project execution

- Competitive pricing and dependable lead times

We supply a complete lineup of New Orleans, LA, CNC services for automation projects:

- CNC Lathe Machining

- Custom CNC Machining for Part Production

- Oil and Gas Precision Machining

- Aerospace Manufacturing

- Automotive Part Manufacturing

- EDM Machining

- High Volume CNC Machining

- Industrial Automation

- Solar Panel Manufacturers

Roberson Machine Company equips manufacturers with CNC automation engineered for accuracy, efficiency, and scale. Learn more at our team and capabilities, request a quote online, or call 573-646-3996 to leverage New Orleans, LA, CNC Machine Automation on your floor.