Precision and quality are paramount at Roberson Machine Company, especially when it comes to crafting high-end plastic parts. Our high-end plastic machining has become an integral part of various industries across the country, providing precision, durability, and versatility.

If you’re looking for a partner to machine your plastic parts, call us right away at 573-646-3996 or contact us online to get started with a quote. Here, we’ll delve into the intricacies of CNC plastic machining, exploring its applications, benefits, and the key considerations that set it apart.

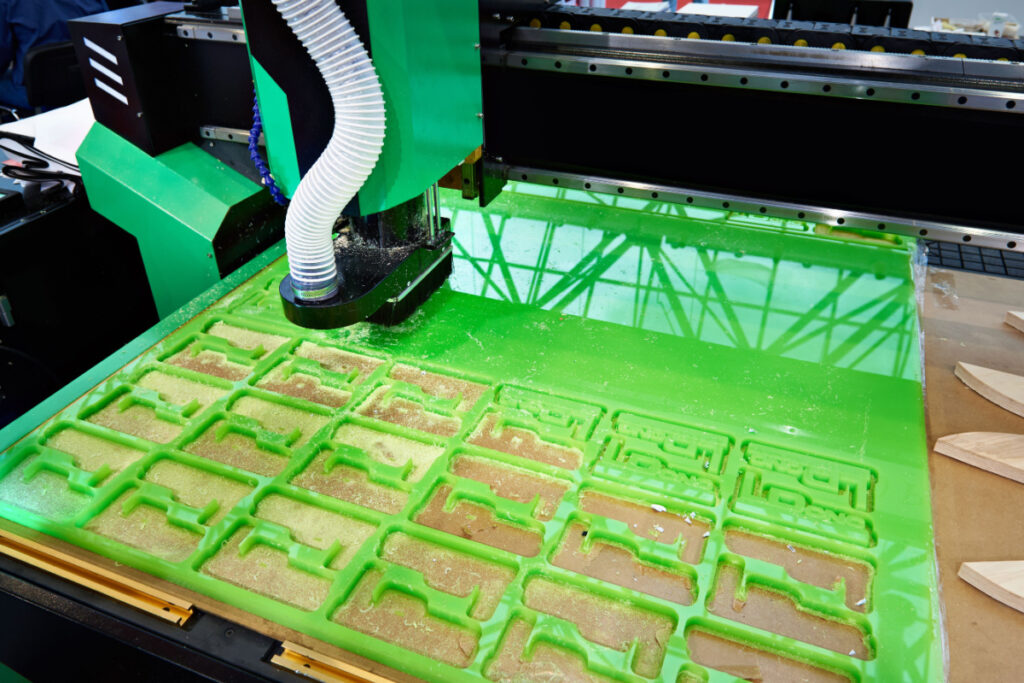

Mastering Precision: The World of High-End Plastic Machining

Roberson Machine Company has over 20 years of experience in CNC plastic machining, providing top-tier customer service, quality control, and timely delivery of your plastic parts. The advantages of choosing us for plastic machining include:

- Versatility: The versatility of high-end plastic machining extends across a variety of industries, each with unique requirements and challenges. We have the capabilities to machine parts for our industry-leading partners in aerospace, which calls for precision-machined plastic components that contribute to lightweight aircraft designs and superior fuel efficiency. In the medical sector, these parts play a crucial role in things like surgical instruments, diagnostic equipment, and implantable devices.

- Precision Engineering: Unlike traditional machining methods that rely on manual intervention and are susceptible to human error, CNC plastic machining at Roberson Machine Company is bolstered by our automation to execute complex geometries with pinpoint accuracy and repeatability. We are also able to eliminate wasted materials.

- Efficiency and Cost-Effectiveness: By automating our manufacturing process and getting rid of material wastage, we streamline production workflows and reduce lead times – passing along the savings to you. Give us a call today for a free quote on your company’s high-end plastic machining needs at 573-646-3996 or contact us online.

- Advanced Materials, Superior Results: One of the most prominent features of plastic machining is the ability to work with a wide range of advanced materials. From engineering-grade thermoplastics to high-performance polymers, we can leverage an extensive selection of materials for your exact part requirements. These materials offer varying levels of heat resistance, chemical inertness, and mechanical strength. Our materials can include:

- Acrylonitrile Butadiene Styrene (ABS)

- Polyethylene (PE)

- Polyetheretherketone (PEEK)

- Acrylic (PMMA)

- Delrin (Polyoxymethylene, POM)

- Polypropylene (PP)

- Polytetrafluoroethylene (PTFE)

- Polyvinyl Chloride (PVC)

The Future of High-End Plastic Machining at Roberson Machine Company

As technology continues to advance, the future of high-end plastic machining looks promising. Our machinists have already become adept in our ever-growing 3D printing services. Additionally, nanotechnology and other forms of additive manufacturing are reshaping the manufacturing landscape, offering plenty of new possibilities for our precision manufacturing.

The integration of artificial intelligence (AI), the Internet of Things (IoT), and machine learning holds the potential to boost machine processes to unprecedented levels, further boosting efficiency and productivity. We can’t wait.

Reach Out to a Leader in High-End Plastic Machining | Roberson Machine Company

In the ever-evolving world of manufacturing, high-end plastic machining stands out as a beacon of precision and innovation at Roberson Machine Company. We have the ability to produce intricate parts with unparalleled accuracy and quality on your project’s precise timelines.

Call us now at 573-646-3996 or contact us online for a quote.