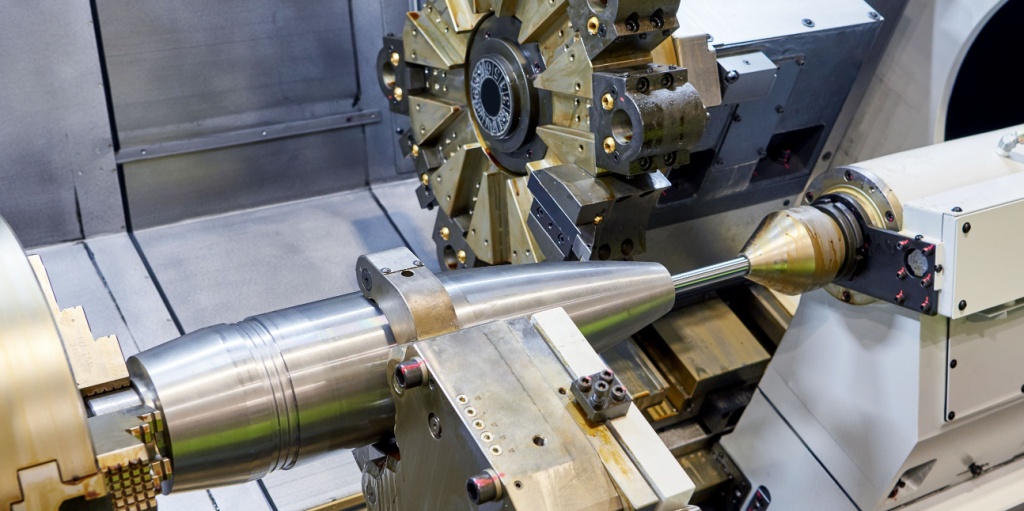

CNC turning becomes the right choice when production starts exposing weaknesses in other machining workflows. Parts may still function, but cycle times stretch, handling increases, and repeatability gets harder to protect as output demands rise.

CNC turning supports high-volume production by keeping critical geometries aligned across repeat runs. That process stability makes it a reliable foundation for high-volume CNC machining, where small inconsistencies can turn into larger production problems.

Below, we’ll walk through:

- How production realities change as output grows, including what actually breaks at high volume.

- When CNC turning fits high-volume and repeat production and where it creates the most value.

- What types of parts scale well with CNC turning as volume and release schedules increase.

- Why choosing the right CNC turning partner matters for long-term consistency and repeat production.

CNC turning, like other machining processes, works best when it fits the production goal. This breakdown focuses on when turning helps stabilize output—and when another approach may make more sense.

What Changes When Production Moves to High Volume

High-volume production doesn’t change what a part needs to do—it changes how unforgiving the process becomes. Small inefficiencies that barely register in short runs start compounding once parts repeat at scale.

As production volume increases, a few things start to matter more:

- Cycle time and handling start dictating output. Seconds per part and extra setups compound quickly in bulk CNC production.

- Feature alignment has to survive repetition. Geometry that lines up once must stay aligned across thousands of parts and future releases.

- Repeat parts expose process weakness fast. High-volume components—like many everyday machinery parts produced by the thousands—don’t hide variation, scrap, or material waste for long.

At this point, process choice stops being theoretical and starts affecting output.

When CNC Turning Fits High-Volume and Repeat Production

In high-volume production environments, turning is a strong fit when repeat output depends on keeping critical geometry aligned over time.

Shared Centerlines Define How the Part Functions

When diameters, bores, and threads must stay aligned relative to a single axis across repeat runs, CNC turning provides a natural advantage. By creating these features from a shared centerline, turning limits runout and reduces geometric drift that becomes harder to control as volume increases.

This centerline-based approach matters in production environments where alignment affects sealing, fit, rotation, or downstream assembly—and where small shifts can ripple outward once parts repeat by the hundreds or thousands.

Reference Geometry Has to Survive Repeat Releases

High-volume and repeat production programs rely on geometry that can be recreated consistently over time. With CNC turning, critical features are established relative to the same reference, reducing tolerance stack-up and avoiding stack-up errors that compound across releases.

When parts return to production months—or years—later, this stability helps prevent the need to rediscover setups, offsets, or alignment strategies that don’t scale cleanly over time.

Fewer Setups Help Protect Consistency at Volume

As production scales, CNC turning supports consistency by completing multiple critical features in a single operation. Reducing setups limits re-clamping and handling—two factors that quietly introduce variation as production scales.

As output increases, each additional setup becomes another opportunity for misalignment or drift. Turning minimizes those handoffs by establishing geometry up front, rather than rebuilding accuracy through secondary operations.

Repeat Output Exposes Weakness Faster Than Prototypes

Processes that appear stable in short runs often behave differently once parts repeat at scale. As volume increases, small inconsistencies in alignment, finish, or geometry surface more quickly and become harder to ignore.

At this stage, maintaining consistency matters more than proving a process can work once. CNC turning fits when preserving alignment helps limit scrap, rework, and material waste across long production runs.

What Types of Parts Scale Well With CNC Turning

The production pressures outlined above show up most clearly in parts that repeat at volume. Many everyday machinery components produced by the thousands rely on CNC turning because their function depends on consistent diameters, alignment, and repeatable geometry.

Production Parts That Benefit Most From CNC Turning

- Shafts, pins, and rotational hardware used in motors, conveyors, packaging equipment, and drive assemblies

- Bushings and sleeves that control alignment and wear in automated machinery and material-handling systems

- Rollers and cylindrical tooling used in production lines where downtime and replacement fit matter

- Sealing and flow components such as valve bodies, manifolds, and other pressure-handling parts

Even highly regulated examples—such as precision valve bodies or alignment-critical components—share the same core requirements as industrial parts: concentric geometry, stable diameters, and repeatable setups.

Industries Where These Parts Show Up

These high-volume, repeat CNC turning parts show up across a wide range of production environments. While the industries differ, the underlying requirements—alignment, repeatability, and stable geometry—remain the same.

CNC turning supports production programs across industries including:

- Medical and regulated manufacturing

- Automotive and EV production

- Industrial automation and robotics

- Aerospace and defense

- Energy and oil & gas

- Food and beverage manufacturing

- Packaging and production equipment

- Military manufacturing

- Industrial automation systems

Beyond industry-specific work, Roberson also supports broader production needs such as contract manufacturing, machined plastic parts, and early-stage programs through prototyping and first-article production.

Choosing CNC Turning for Repeat Production

When parts repeat at volume, CNC turning earns its value over time by holding geometry, alignment, and consistency across every release—not just the first run. Roberson Machine Company applies CNC turning with production execution in mind, supporting high-volume CNC machining programs that need to scale, pause, and restart without losing control.

- Documented setups, tooling strategies, and inspection plans support repeat runs without reworking the process every time production restarts.

- One-setup and turn–mill workflows reduce handoffs, re-clamping, and alignment risk as volume and scheduling pressure increase.

- Production programs are managed with high-volume CNC machining experience, sustaining output across repeat releases rather than treating work as one-off jobs.

If you’re evaluating CNC turning for a repeat or high-volume program, contact our team or call 573-646-3996 to talk through fit, volume, and production requirements.