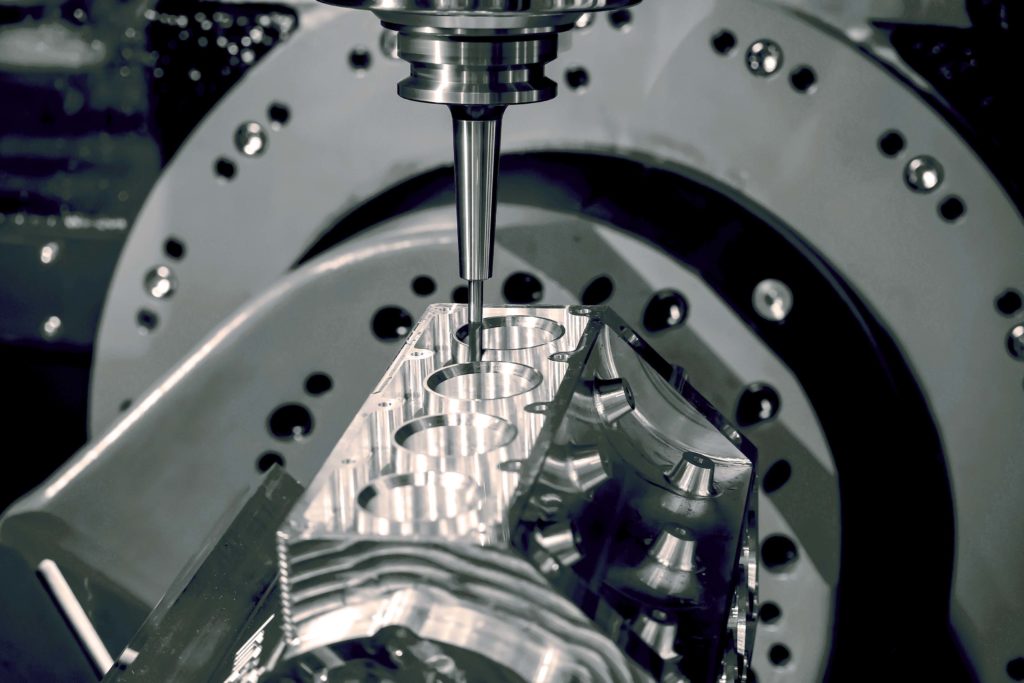

CNC machining is a versatile manufacturing process used to create precise and complex parts and products for a wide range of industries. It is the forefront of what we do at Roberson Machine Company, our bread and butter, if you will. One crucial factor that significantly impacts the success of CNC machining projects is material selection.

Choosing the right material is essential for achieving desired outcomes in terms of functionality, durability, and cost-effectiveness. Whether it’s aluminum, brass, stainless steel, titanium, copper, plastics, or composite materials, Roberson Machine Company has the experience to steer you in the right direction.

Call us right away at 573-646-3996 or contact us to speak to a specialist about material selection for your next project. In this post, we’ll explore the importance of material selection and provide valuable tips and best practices to help you make informed decisions.

What Types of Materials Does Roberson Machine Company Normally Use?

Our scope of materials available for CNC machining includes:

ALUMINUMS

A wide range of aluminums including: 6061, 6063, 6082, 7075, 7050

STEELS & ALLOYS

A wide range of steels and alloys including: A-36, C1018, 4140, 1045, A2, D2, S7

STAINLESS STEEL

A wide range of stainless steels including: 17-4, 303, 304, 316, 321, 347, 420SS, 416, 440

OTHERS

A wide range of plastics including: Delrin, Nylon, PEEK, HDPE and Glass Filled Nylon. Other metals including: Bronze and Brass

Key Factors in Selecting Materials For CNC Machining

Before choosing one of the many materials available in our shop, some of the following factors can help narrow things down:

- Overall Functionality and Performance

- Machinability

- Strength

- Tensile strength measures the level of resistivity of a material to external forces

- Compression shows how much a material can accommodate under steady pressure

- The level of toughness is found by the level of resistance of a material to wearing and tearing

- Elasticity shows the material’s ability to return to its original shape after the stress that caused the deformation is no longer applied

- Corrosion Resistance

- Heat Resistance

- Dimension Tolerance

- Material Cost

The first consideration when selecting materials is the intended functionality and performance of the final part. If you need high strength and durability, metals like aluminum or stainless steel might be suitable, while plastics like ABS or nylon could be preferred for the lightweight and impact-resistant properties.

The right material should have high machinability as this will increase productivity and reduce damage to parts. Examples of high machinable materials include light metals such as aluminum, brass, copper, and some plastics. On the opposite end, tough metals and strong plastics like carbon fiber have a low level of machinability.

Machining a material with low machinability reduces the quality of parts and overall efficiency, and can destroy metal parts. Also, these materials frequently require switching out unique cutting tools which increases production time and costs.

Call Roberson Machine Company now at 573-646-3996 or reach out to us online.

A major factor you should consider when selecting a material for your CNC machining project is the strength of the material. Whether you’re choosing between metals, plastics, or composites, there are several ways to measure a material’s strength, including:

Water, along with other substances including salt, grease, oil, acids, alcohol, can cause varying levels of corrosion. Resistance to corrosion plays a huge role in determining the application of the material. As examples, aluminum is consistently used in the electronics industry and stainless steel is suitable for marine applications.

Heat resistance measures the level of adaptability of material to temperature changes. The correct CNC materials will show regular contraction and expansion when temperatures rise or fall. As a result, there will be no deformation due to the heat generated during machining.

Materials that support tight dimensional tolerance have high machinability and low variability.

The cost can be the most crucial factor. Generally, metals are more expensive than plastics. However, you should make sure you pick a material that works best for your application. We are always willing to work with you on cost-saving measures and value-added materials.

Get the Right CNC Machining Material for Your Projects | Roberson Machine Company

Roberson Machine Company is here to help if you are struggling to choose the right materials for your next project. The importance of material selection in CNC machining cannot be overstated. It directly impacts the functionality, performance, cost, and overall success of your projects.

With our single-source manufacturing service to meet and exceed your expectations, you can confidently get CNC machined parts with high quality and accuracy. Call us today at 573-646-3996 or contact us online.