The use of aluminum in the CNC machining process has increased dramatically in recent years, as has the production of CNC automotive parts and other lightweight components. Roberson Machine Company is an industry leader in providing aluminum parts and services.

Aluminum is the most widespread metal on Earth, making up more than 8 percent of the planet’s core mass. It is the second most malleable and sixth most ductile material on the planet. It’s also the third most common chemical element on Earth, behind only oxygen and silicon.

Call Roberson Machine Company today at 573-646-3996 or connect with us online regarding your next aluminum machining project.

Why Use Aluminum for My Company’s Custom Manufactured Parts?

In addition to being versatile, aluminum has become a go-to choice for many parts. Some of the reasons our customers turn to aluminum include:

- It has a high strength-to-weight ratio, making it easier for machine shop owners to produce parts for industries such as aerospace and automotive.

- Because aluminum is resistant to corrosion, it is ideal for making parts for industries that use components that are exposed to extreme weather and temperatures.

- Due to its softness, aluminum cuts easily and requires less power from the machine.

- Even at the lowest temperatures, aluminum retains its primary properties of flexibility, softness, and strength.

- Aluminum is an affordable and highly recyclable material.

Why Does Roberson Machine Company Use Aluminum For CNC Machining?

At Roberson Machine Company, we put quality first. We deliver complex, precise aluminum parts and products in less time than our competitors because of our knowledgeable team of specialists. Give us a call now at 573-646-3996 or contact us online. The following factors make aluminum the ideal option for custom parts:

- Aluminum is easy to machine

- Aluminum has an excellent strength-to-weight ratio

- The grain structure is improved by alloying, or mixing with other elements

- To create sized crystals, heat treatment involves heating and cooling at a specific rates

- Aluminum has excellent conductivity

- Recyclable

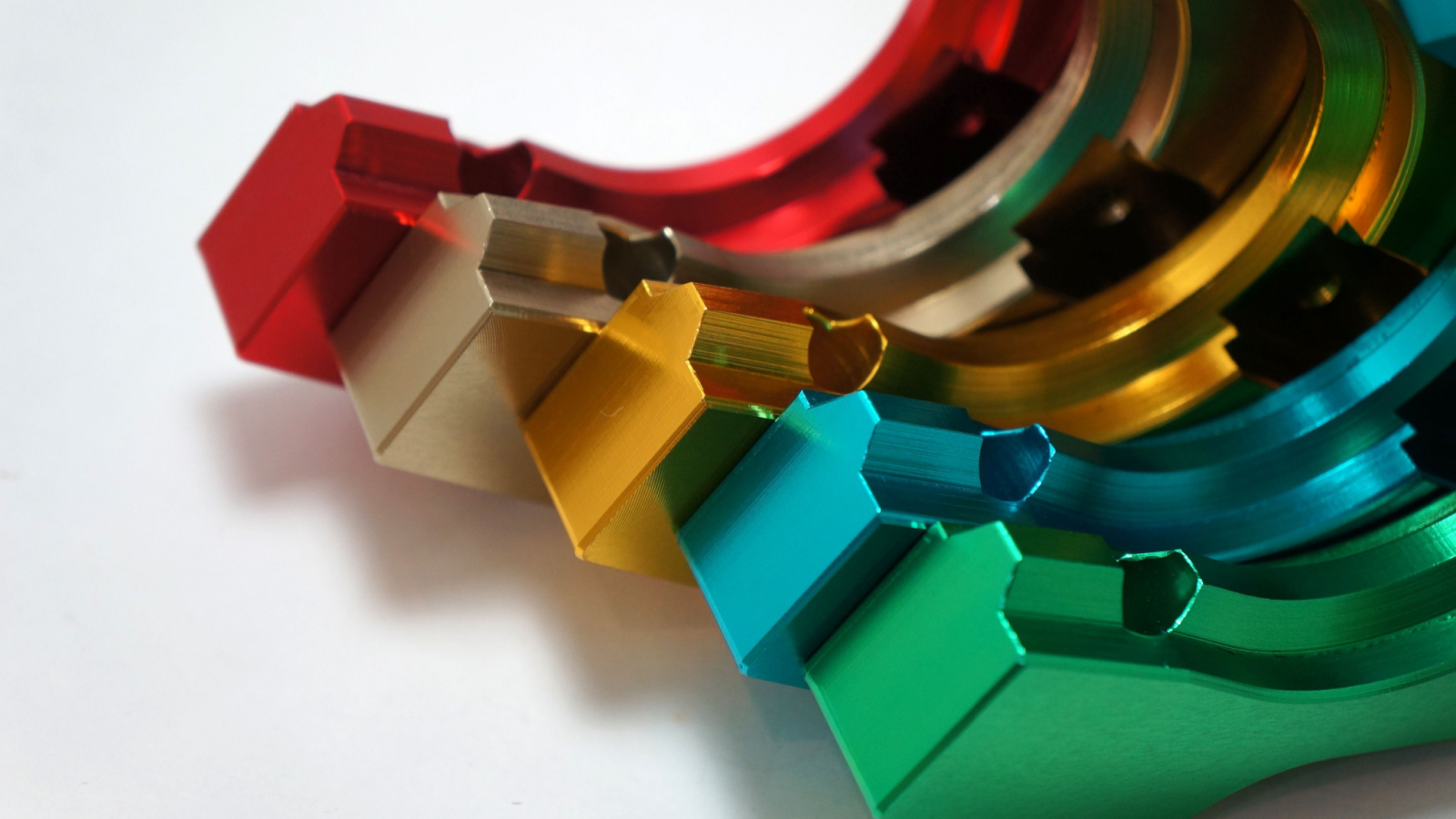

Because aluminum is dimensionally stable, we can remove a large portion of it while keeping residual stress under control. We get a finish using carbide tooling and modern coolants. Aluminum can also be bead blasted for a matt finish or anodized for a consistent aesthetic finish and added corrosion resistance.

Aluminum is lighter than most metals, making it an excellent choice for weight reduction. Although pure aluminum has a tensile strength of less than 100 megapascal, it gets hardened in the following ways:

While copper gets used consistently for conductivity, electrical components frequently use aluminum because it is much cheaper and lighter. It gets used for battery cables, busbars, and connectors, particularly in automotive and electric vehicle applications. Due to its high thermal conductivity, it gets used for heat sinks and heat dissipation.

With environmental concerns at the forefront of what we do, it’s encouraging to know that an estimated 75 percent of all aluminum produced is still in use. Recycling aluminum uses far less energy than creating it, and as long as impurities are kept under control, aluminum gets reused indefinitely.

Is Aluminum the Best Material For Your Next Project?

As the above characteristics suggest, aluminum has many advantages and is machinable with our CNC machines. Is aluminum the best material for your project, though? If you need a readily available metal with a high strength-to-weight ratio and good machinability, then yes, it is ideal for you. Also, if your part or product will get exposed to moist or extreme environments, you should choose aluminum because aluminum alloys are generally resistant to corrosion.

Why CNC Aluminum Machining Is Ideal For Your Business | Roberson Machine Company

For over 20 years, Roberson Machine Company has been the place to turn for all of your custom aluminum machining needs, providing skilled techniques with detailed precision. We have customers and partners in every industry that appreciate our dedication to timeliness, our central location, and our low costs.

Give Roberson Machine Company a call right away at 573-646-3996 or reach out to us online.