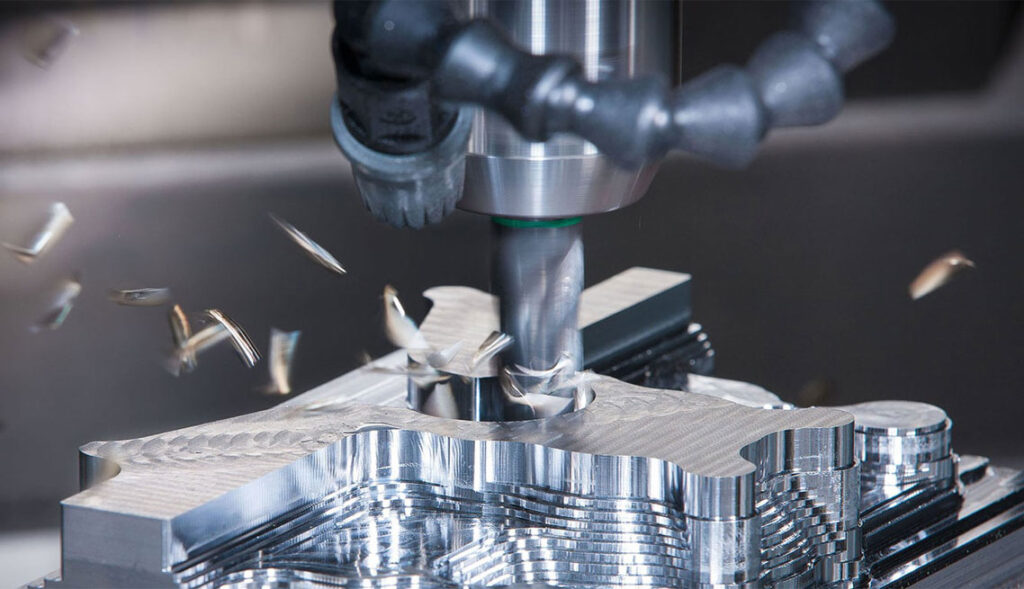

CNC turning at Roberson Machine Company is no one-trick pony. It is a multifaceted manufacturing solution capable of executing numerous operations on a multitude of materials for your company. These operations can be performed with great precision and repeatability, making CNC turning a preferred choice for machining complex components in various industries.

Give the CNC turning specialists at Roberson Machine Company a call today at 573-646-3996 or contact us online for a free quote. We have over 20 years of experience delivering CNC machining and manufacturing solutions to industry-leading clients across the country.

What Operations Can Be Performed With CNC Turning at Roberson Machine Company?

CNC turning is a versatile machining process that can perform various operations to manufacture precise and intricate parts. Some of the key operations that can be carried out with CNC turning include:

External Turning Specific Operations

- Turning: This primary CNC operation involves rotating the workpiece on a lathe while a cutting tool removes material to create cylindrical shapes, like shafts and gears.

- Hard Turning: This specialized operation focuses on materials with high hardness ratings. Hard turning often replaces grinding and involves cutting materials that are hard to shape, and is known for its precision and ability to achieve fine finishes.

- Taper Turning: Taper turning is used to machine conical shapes by gradually changing the diameter of the workpiece over its length. This process is optimal for your components that need to fit into specific angular spaces, like cones and tapered shafts.

- Facing: This operation is used to create a flat surface on the end of a workpiece. Facing ensures that the end is perpendicular to the axis of rotation.

- Grooving: CNC turning can be used to cut grooves on the surface of the workpiece, allowing for the creation of features like O-ring grooves, oil grooves, or retaining rings. This is especially useful for parts requiring specific recesses and fits.

- Parting: Also known as cutoff or parting off, this operation involves cutting the finished workpiece from the remaining material, likely completing the manufacturing process.

Internal Nonspecific Operations

Our CNC turning machines and CNC lathes come in different variants, some having unique cutting features, making them ideal for specific operations. Having a variety allows us the ability to cater not only to you and your specifications, but to your part design. Call us now at 573-646-3996 or reach out to us online to begin the quote process. These are some of our internal CNC turning operations:

- Drilling: Our CNC turning centers can be equipped with drilling tools to machine holes in the workpiece. This is useful for components requiring assembly, like those needing bolts or pins. Our quality control measures ensure that these holes are drilled with precision to your specifications, both in terms of diameter and depth.

- Threading: This operation involves creating internal or external threads on a workpiece, allowing it to be screwed into other components.

- Boring: Boring operations involve enlarging existing holes or creating precise internal diameters within the workpiece. This is particularly important for parts where hole diameter plays a critical role in functionality.

- Knurling: Knurling is a process that adds a textured pattern to the surface of the workpiece, providing enhanced grip or aesthetic appeal. This is commonly used on tool handles, knobs, and fasteners.

Whether we are operating on a CNC turning center or one of our lathes, Roberson Machine Company draws on the precision, efficiency, and versatility to effectively manufacture your company’s parts within your timeline. In addition to our turning services, we provide:

- CNC Milling

- Wire EDM

- 5 Axis Machining

- Multi Axis Machining

- Aluminum CNC Machining

- Stainless Steel Machining

- Prototype Machining

Reach Out to the Roberson Machine Company Pros Today to Find Out: What Operations Can Be Performed With CNC Turning?

Discover unrivaled accuracy with Roberson Machine Company’s CNC turning services. You need a partner that stays on top of changing technologies in an ever-evolving field. We’re your partner; we’re here to help by providing you with the best manufacturing solution for your parts and project.

Call us today at 573-646-3996 or get a free quote by contacting us online.