When you need hundreds — or thousands — of identical components to arrive on time and fit your workflow, “lathe-friendly parts” are what keep pricing steady and production running the way it should. For more than 20 years, the team at Roberson Machine Company has helped companies reach high-volume part production with next-level CNC lathe machining and other strategies that remove friction from bulk manufacturing.

A lathe-friendly part uses predictable geometry and workflow efficiencies to move through quoting faster, run cleanly in production, and repeat across releases without drifting on cost or quality.

Below, we’ll cover:

- What makes a part run cleanly at volume on CNC lathes

- The core traits that keep high-volume lathe production smooth

- How lathe-optimized designs simplify bulk ordering

- Common lathe-friendly parts

- Cross-industry CNC services and the latest bulk production methods

- Getting the lathe-friendly components your operation needs

Need bulk components that run reliably at scale? Request a quote or call 573-646-3996 to learn how we streamline CNC lathe production for high-volume orders.

What Makes a Part Lathe-Friendly for High-Volume Manufacturing?

A “lathe-friendly” part is one that runs fast, repeats cleanly, and doesn’t cause surprises when you scale from dozens to thousands. For buyers, that means:

- Lower unit cost at higher quantities

- Clean, predictable geometry that stays consistent

- Reliable scheduling with no unexpected delays

- Stable repeatability across every release

When we review high-volume work, these are the core traits that make a part run efficiently and cost-effectively on CNC lathes. It’s why service teams get shafts and pins that install cleanly the first time, OEMs get housings that line up with their assemblies, and production lines quit burning hours on parts that should’ve been right from the start.

6 Factors for Smooth, Scalable Lathe Production

At the simplest level, “lathe-friendly” means a part that runs fast, repeats cleanly, and scales without surprises. These traits are what keep conveyor shafts from drifting out of spec, hydraulic fittings sealing the way they should, and packaging-line rollers showing up identical from batch to batch. From a 10,000-foot view, this means:

1. Geometry That Scales Cleanly

Stable diameters, clear shoulders, and concentric features keep everything tied to one centerline — the foundation of fast, repeatable turning. When geometry stacks well, unit cost drops because the machine spends more time cutting and less time repositioning.

“Unit cost” also considers operational time, labor, material handling, shipping, and other factors.

2. Minimal Flips or Repositioning

The fewer times a part leaves the spindle, the faster and cheaper the run becomes. One-and-done parts always win — especially on multi-spindle systems like the Puma TT1800SY, where handoff is automatic and geometry stays tight.

- Two-sided features finished in one cycle

- No manual flipping or indicating features back in

- Same centerline from start to finish

3. Features That Play Well With Live Tooling

If cross-holes, slots, flats, or tap-drill features can be added mid-cycle, the part avoids a move to the mill. That alone can cut hours from the schedule and stabilize cost on repeat orders with measured live tooling.

4. Materials That Behave at Scale

Aluminum, stainless, brass, mild steels, alloys, and many polymers all run cleanly in bar-fed turning. Tougher materials still work — they just need tooling strategies dialed for longer runs.

- Predictable chip control

- Manageable tool wear

- Good performance in continuous workflows

5. Dimensions That Support Bar Feeding

Parts that fall within a stable length-to-diameter ratio feed smoothly and eject reliably. If it bar-feeds well, it scales well — period.

6. Clear Functional Callouts

Drawings with prioritized features — threads, sealing surfaces, shoulder heights, fits, tolerances — allow us to lock the process early.

Locked processes produce parts that behave the same way every time. This means the same tools, the same offsets, the same cycle times, and the same geometry.

That’s the point of lathe-friendly design: not just a part that “machines well,” but a part that produces well at volume. Contact our team now to learn how to incorporate these guidelines into your workflow.

Why Lathe-Optimized Parts Make Bulk Ordering Easier

Most buyers don’t want a lecture on tooling paths — they want parts that show up on time, match the print, and stop causing problems on the floor. That’s where lathe-friendly design pays off. When a part lines up with how a CNC lathe actually works, everything downstream gets easier: quoting, scheduling, first-article approval, and every repeat order after that.

Here’s what that means for anyone managing releases or stocking production lines:

- Faster quoting: When a part fits a lathe’s workflow, the jump from print to price is quick. Clear features mean predictable cycle times and reliable cost-per-part estimates.

- Predictable delivery dates: Fewer setups and a single centerline keep the job tied to one workflow instead of ping-ponging between machines. That stability keeps delivery dates steady across every release.

- Lower unit cost at volume: Bar-fed CNC turning turns raw material into finished parts nonstop — no flipping, no reindicating, and no downtime between ops.

Once the process is locked, the 500th, 2,000th, and 20,000th part match the first. For big runs, even a small deviation can mean wasted material, blown deadlines, or entire batches in the trash.

If you need thousands of reliable components, a lathe-friendly design isn’t just “good manufacturing etiquette.” It’s your fastest path to fewer delays and a steady production pipeline.

Common Lathe Components for Mass Production

Most high-volume components start with turning of some sort. Below are a few of the common parts that repeat well at scale or are lathe-adjacent somewhere in the production process:

- Shafts, pins, and bushings – core lathe work with steady diameters and clean shoulders.

- Rollers and cylindrical tooling – conveyors, labelers, presses, and ink rollers that rely on concentricity at volume.

- Valve bodies and fluid-system components – round bodies, sealing surfaces, and precision bores common in medical, hydraulic, and energy systems.

- Housings, caps, and threaded enclosures – round sensor housings, pump caps, threaded covers, and other parts built around a centered bore.

- Turn–mill hybrids – couplings, small manifolds, and end-of-arm tooling with milled flats, slots, or patterns added after turning.

- Instrumentation and medical hardware – microscope components, valve bodies, and acrylic instrument parts that start as turned blanks.

- Drive components – precision shafts and drive-shaft assemblies used across OEM equipment.

The common thread: each part depends on round, repeatable geometry that a CNC lathe delivers better and faster than any other process — especially when paired with live tooling or multi-spindle systems for added features.

CNC Services, Industry Partnerships, Latest Bulk Production Methods

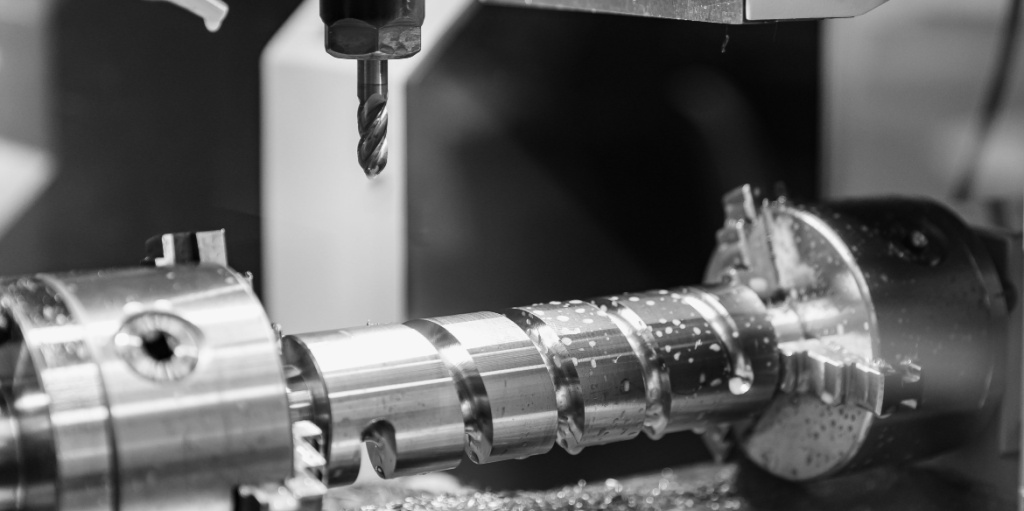

If you’re designing or buying parts that need to be lathe-friendly, you also need a shop that can run them at volume without surprises. Roberson Machine Company combines CNC lathe machining with milling, multi-axis work, and EDM to take parts from print to production. Our newest lathe — the Doosan Puma TT1800SY — adds twin-turret, multi-spindle capacity for two-sided and multi-op parts that need to ship by the hundreds or thousands.

Core CNC capabilities include:

- CNC Lathe Machining – high-volume shafts, bushings, rollers, fittings, and other round components built around a stable centerline.

- CNC Turning – production turning with bar-fed workflows, sub-spindle handoff, and live tooling where it makes sense.

- CNC Milling – flats, pockets, bolt patterns, and mating surfaces that complement lathe work.

- Multi-Axis Machining & 5-Axis – complex angles and multi-face features that still need to tie back to turned geometry.

- Wire EDM – tight internal profiles, hard materials, and details that sit beyond conventional cutting tools.

- High-Volume CNC Machining & CNC Machine Automation – repeatable workflows, locked processes, and predictable cycle times for longer runs.

We handle production manufacturing for oil and energy, automotive, medical and pharmaceutical, automation and robotics, packaging, aerospace, food and beverage, OEM/specialty manufacturing, and other industries. If your equipment moves, seals, measures, fills, or handles anything at scale, there’s a good chance we already machine the kind of parts you need and have experience working within your field.

Get in Touch With Our Team Now

Learn more from our reviews, recent case studies, blog, and FAQs, then request a quote online or call 573-646-3996. We’ll help you turn lathe-friendly designs into a steady stream of parts that show up when your operation needs them.