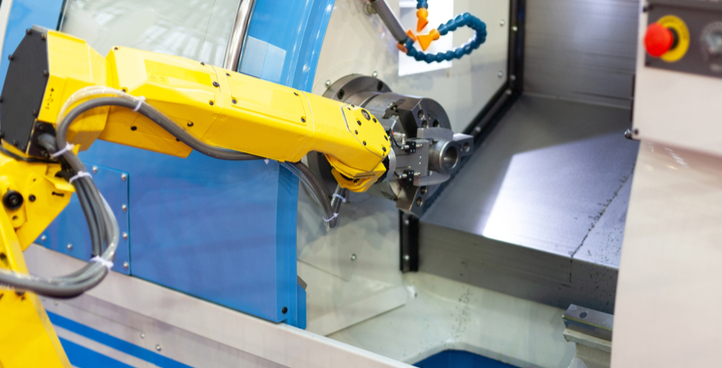

Robotic machine tending, also called automated machine tending, is a technology that uses robotic controllers and arms to move the product from a supply position, transport it to the machine, position it correctly, and then remove the finished piece—all with the same motion and repeatability over and over again.

At Roberson Machine Company, we have invested in the use of robotic tending in order to increase capability in our CNC machining process. With this new technology at our disposal, we are able to load and unload projects as small as a dime and as large as a refrigerator at amazing cost savings that we pass onto our customers. Learn more about the advantages of partnering with a machining company that uses robotic machine tending to produce consistent parts and reduce lead times. Contact us or call 573-646-3996.

Advantages of Partnering with a Contract Manufacturer that Uses Robotic Machining

- No human operators – No matter how fast the CNC machining process operates, items are only produced as fast as they can be loaded. In the past, human operators had to load these workpieces into the equipment, which not only increased the potential for human error but also production downtime. After all, machining shops cannot run shifts for laborers around the clock. By replacing human operators with robotic capabilities, we can help keep downtime at a minimum as well as reduce the cost of human labor.

- Lower risk of waste – When managing the flow in and out of the machining center, the robotic arms travel the exact same path when placing the part in the same position each time. There is no deviation, slight movement, or error in the placement which can often happen when human operators place workpieces, in turn, reducing waste associated. Overall, lower waste means lower cost of production as well as increased efficiency.

- Decreases loading and unloading time – These robotic arms can be set to work around the clock to the speed of the production CNC machining equipment, shaving off production time by eliminating gaps in loading and unloading the equipment. Rather than having someone load and unload one machine at a time, we can now have one employee oversee the operation of multiple robotics systems and to respond to any issues that occur.

- High quality consistent products at half the time – By programming your exacting specifications into the computer numerical control systems, you can continuously meet tight tolerances not only at a rapid pace but in both large-volume orders and small runs. With the capability to produce components to a higher standard of quality and faster allows us to carry out higher quantities of production. In short, we provide our customers more for less!

- Cost savings passed onto customers – Overall, robotic machining reduces the cost of production which translates into lower costs for our customers. This has a significant impact on not just our bottom line but the bottom lines for the OEMs—both large and small— that use our services.

Contact Our Contract Manufacturers in Missouri | Roberson Machine Company

Robotic machine tending is typically used for loading and unloading parts in CNC machining applications, such as CNC turning, CNC milling, stamping, trimming, punching, forging and more.

We’ve worked tirelessly to offer superior quality to our customers, all while lowering their price points to make their production runs easier to manage. We believe that our use of robotic technology contributes to our flexible service delivery, wide range of turn-key product solutions, and consistently high standards. Contact us to discuss your CNC machining project now or call 573-646-3996 to get a free quote.