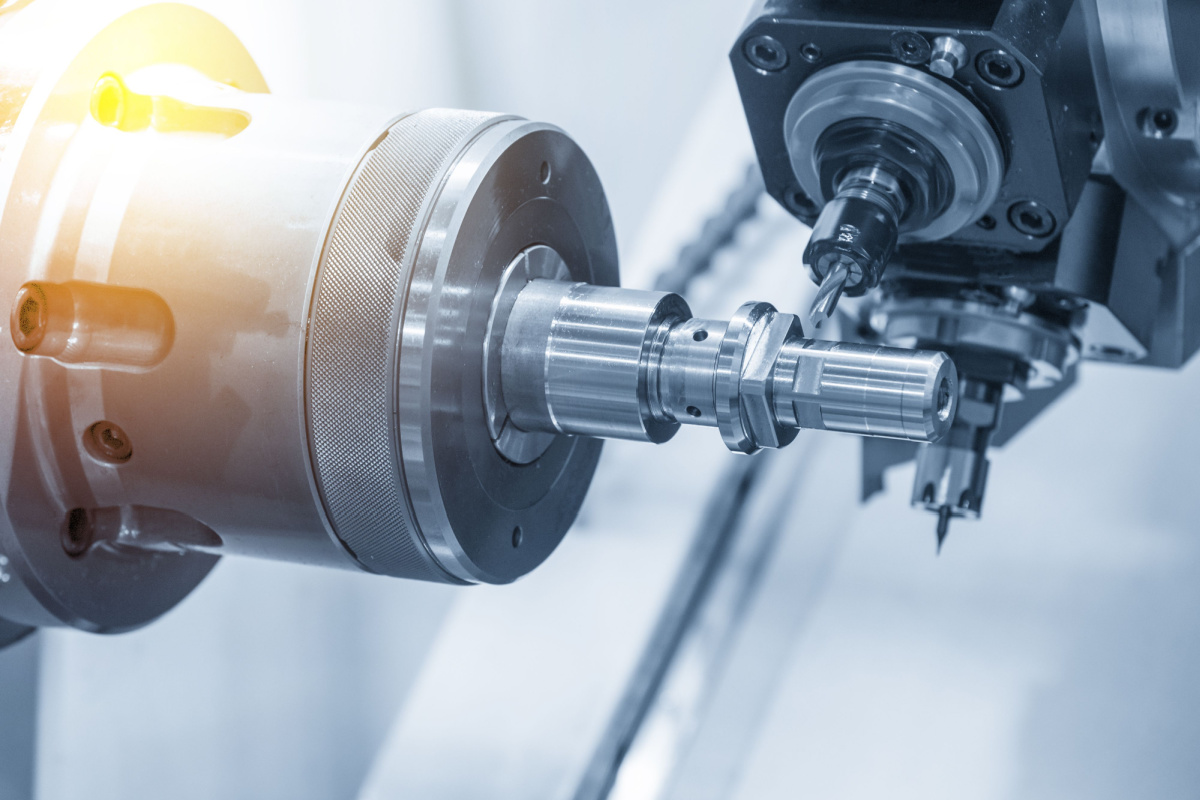

In modern manufacturing, precision, speed, and efficiency are the pillars of success. When it comes to machining intricate components for industries from aerospace to medical and everywhere in between, your choice of a manufacturer and machining technology can be the difference between excellence and ho-hum mediocrity. Roberson Machine Company is here to change the game with our Computer Numerical Control (CNC) services.

Due to these unrivaled CNC machining services and our skilled staff, we can deliver highly precise, made-to-order components that adhere to your company’s precise specifications. Call Roberson Machine Company as soon as possible at 573-646-3996 or contact us online for a free quote.

CNC machining is more than simply a process in the ultra-competitive world of manufacturing – it’s a strategic advantage at Roberson Machine Company. Excellence is our benchmark, and we settle for nothing less than what you expect. No matter if your company’s project consists of aerospace components, parts for medical devices, or automotive products, our CNC machining solution is your key to unlocking precision and efficiency beyond expectations.

Why Choose CNC Machining at Roberson Machine Company?

Roberson Machine Company is your go-to choice when it comes to CNC machining. We make it easy for you by providing manufacturing solutions up front, coupled with a detailed timeline and budget. Give us a call today at 573-646-3996 or reach out to us online for your free CNC machining quote and to find out more about these advantages:

Constant Contact and Reduced Human Error

Depending on your company’s needs, our CNC machines can operate 24 hours a day, 7 days a week due to our robotic machine tending. Automation ensures a significant reduction in human error, along with constant precision and efficiency, making it an invaluable asset for large-scale manufacturing. You can have the confidence that your components will precisely meet your specified design.

Tailored to Your Company’s Needs

Our CNC machines are programmable to suit your exact needs. They allow us to produce a wider range of sizes, shapes, and textures than ever before, giving you more freedom in your part designs. Whether your project calls for CNC milling, CNC turning, or multi-axis machining, our specialists can tailor our machines and solutions to your exact requirements.

Complex Geometry Made Simple

The CNC machines at Roberson Machine Company can effortlessly tackle intricate and complex shapes that conventional machining methods can’t touch. Whether it’s for manufacturing parts with tight tolerances, complex designs, or unique forms, shapes, or paths, CNC machining has the versatility and ability to handle it all.

Unmatched Consistency

One of the key attributes of CNC machining is the method’s ability to replicate precision parts consistently. Our specialists control tool calibration and operating environment in our shop, allowing for surefire accuracy. Every part produced using our CNC services is an exact replica of the previous one, time and time again, ensuring uniformity across your production run. This is critical for industries where consistency is paramount.

Increased Options With CNC Software

Our CNC machines run on a set of CAD and CAM programmed code. The CAD software designs the models and assemblies that the CAM software translates into G-code and M-code that drive the CNC machine’s tools to turn those designs into physical parts. This software allows for a fine-tuned ability to quickly translate your part designs into action, as well as being able to adjust parameters on the fly.

Swift Prototyping and Design Retention

As opposed to the conventional prototype method of having a machinist create the design by hand, CNC machining allows you to quickly create one via CNC code. This gives you the option of viewing a three-dimensional prototype or a physical one, depending on your company’s needs. Additionally, our machines are able to save prototype designs for future production runs – helping with efficiency and ensuring your parts are identical.

Discover All the Reasons to Choose CNC Machining for Your Manufacturing Needs | Roberson Machine Company

We pay extremely close attention to every part we manufacture for you, along with our quality control management. Our specialists continually review and cross-reference our work processes and benchmarks to ensure we are at our best for our customers. Our internal standards adhere to ISO 9001 and AS9100 certifications. We are always here to help on your next CNC machining project.

Call Roberson Machine Company today at 573-646-3996 or contact us online for your free quote.