In the dynamic realm of precision manufacturing, a revolutionary force has emerged, transforming the way we at Roberson Machine Company conceptualize and produce intricate components.

3D printing has become a game-changer for us, offering new possibilities and efficiencies that were once thought unattainable. To learn more about the enticing world of 3D printing and what it can offer your company, call us as soon as possible at 573-646-3996 or contact us online for a free quote.

Here, we’ll delve into the impact of 3D printing on precision manufacturing techniques, exploring its benefits, applications, and the ever-evolving landscape of this innovative technology.

How 3D Printing Reshapes Precision Manufacturing Techniques at Roberson Machine Company

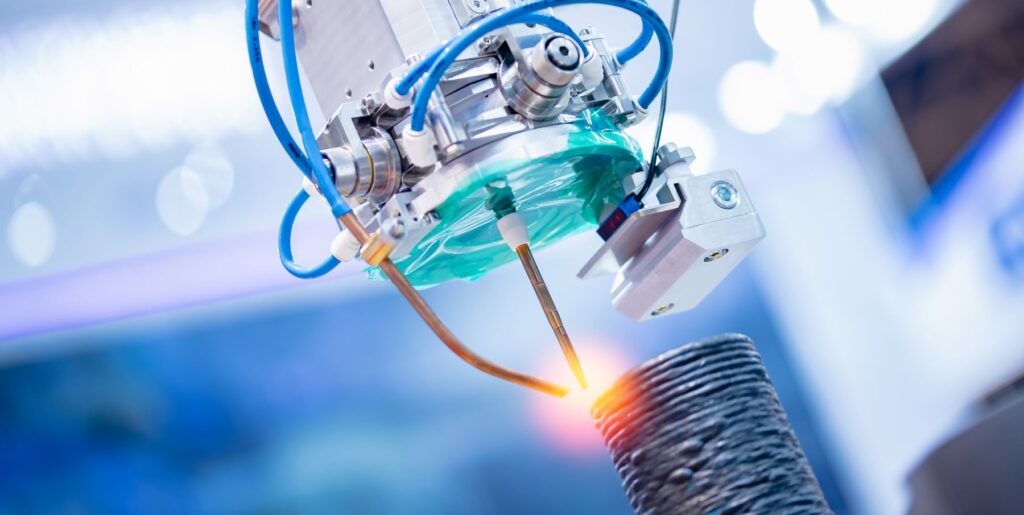

3D printing, also known as additive manufacturing, builds objects layer by layer from digital models. This layer-by-layer process allows us unparalleled precision and customization of your parts, making it a go-to option for a variety of industries.

Precision is the hallmark of 3D printing at Roberson Machine Company. With our high-resolution printers and advanced materials we can produce complex geometries with tight tolerances, ensuring that each layer aligns precisely with the digital model. This level of accuracy is crucial in sectors where parts must fit seamlessly and function flawlessly.

Advantages of 3D Printing in Precision Manufacturing at Roberson Machine Company

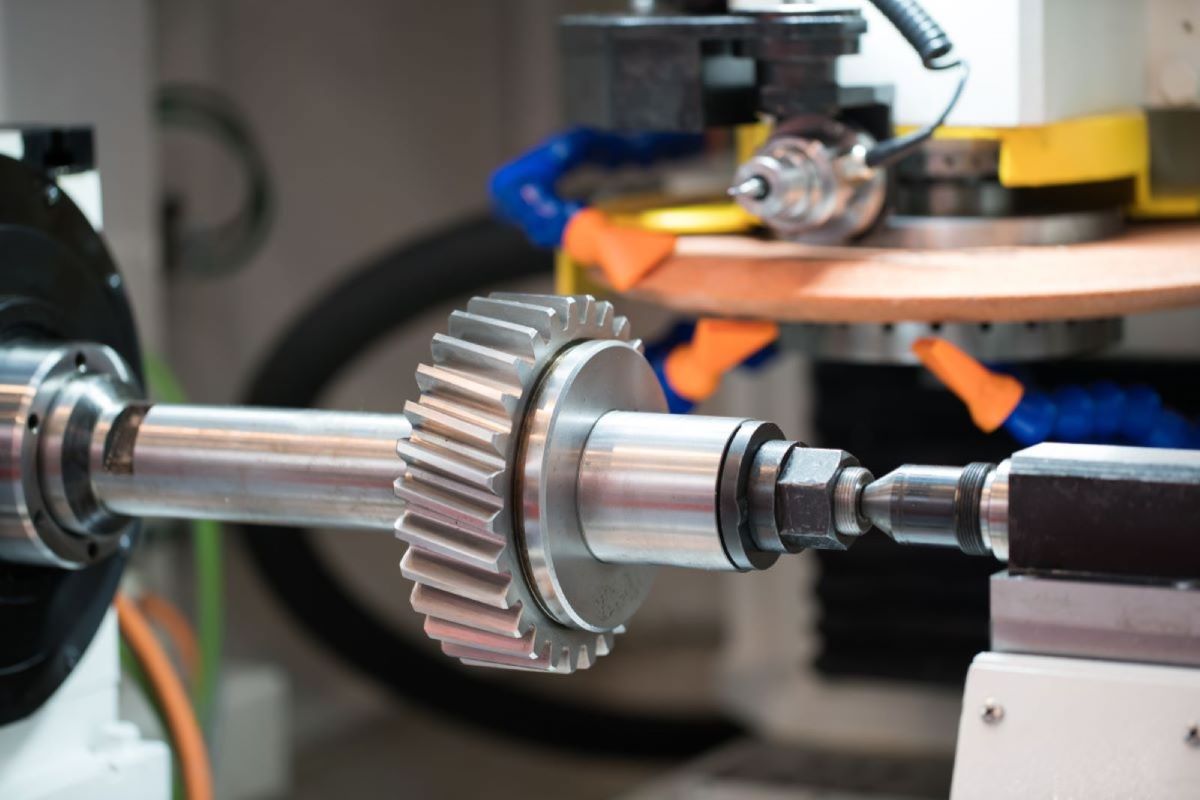

Our 3D printing technology, coupled with our CNC machining and unmatched manufacturing solutions for clients, separate us from other companies. The following are just a few benefits of choosing us for your 3D printing and precision manufacturing needs:

- Rapid Prototyping

- Cost and Time Savings

- Reduced Waste

- Design Customization and Flexibility

One of the biggest benefits of our 3D printing services is rapid prototyping. We can swiftly produce prototypes using our computer-aided manufacturing (CAM) and computer-aided design (CAD) software. This enables us to iterate designs, test functionality, and identify flaws quickly and effectively.

Our 3D printers can quickly produce accurate and intricate components, reducing the time required for molds, dies, fixtures, and tooling, and eliminating unnecessary upfront expenses. 3D printing also reduces labor costs and boosts accuracy with our automated processes. Call us right away at 573-646-3996 or reach out to us online for a free quote.

Traditional manufacturing processes frequently result in significant material wastage. 3D printing in our shop though, adds material selectively – using only enough to create a component – minimizing waste and contributing to more sustainable practices.

Industries requiring highly customized components, like the medical and aerospace sectors, benefit from our 3D printing capability to tailor designs to specific requirements, ensuring a perfect fit and functionality. Also, 3D printing can produce parts with greater design flexibility than traditional methods, allowing for complex shapes and features that may otherwise be difficult or impossible to produce.

The Applications of 3D Printing and Precision Manufacturing Techniques

As the technology continues to evolve, the synergy between 3D printing and precision manufacturing will deepen. Numerous applications currently exist. These are just a few:

- Automotive: Automotive clients can leverage our 3D printing for rapid prototyping, intricate components, and end-use parts. We are able to accelerate the production process while maintaining the necessary precision and strength.

- Medical Devices: The medical device industry can benefit from our 3D printer’s ability to produce patient-specific implants, prosthetic devices, and surgical guides. This can not only improve patient outcomes, but also allow for tailored solutions based on individual anatomies.

- Aerospace: 3D printing at Roberson Machine Company can revolutionize our aerospace manufacturing solutions by allowing for the creation of lightweight, yet durable parts. From intricate engine parts to complex frame structures, this technology can boost fuel efficiency and overall performance.

How 3D Printing is Reshaping Precision Manufacturing Techniques | Roberson Machine Company

The marriage of 3D printing and precision manufacturing has ushered in a new era of possibilities. As the technology matures and becomes more accessible, its impact and popularity will only intensify. Embracing this transformative force allows Roberson Machine Company to stay at the forefront of innovation, redefining what is possible for our clients through the world of precision manufacturing.

Give us a call now at 573-646-3996 or contact us online to get a free quote on your company’s next project.