3 Axis Machining Questions and Answers

1. What is 3 axis machining?

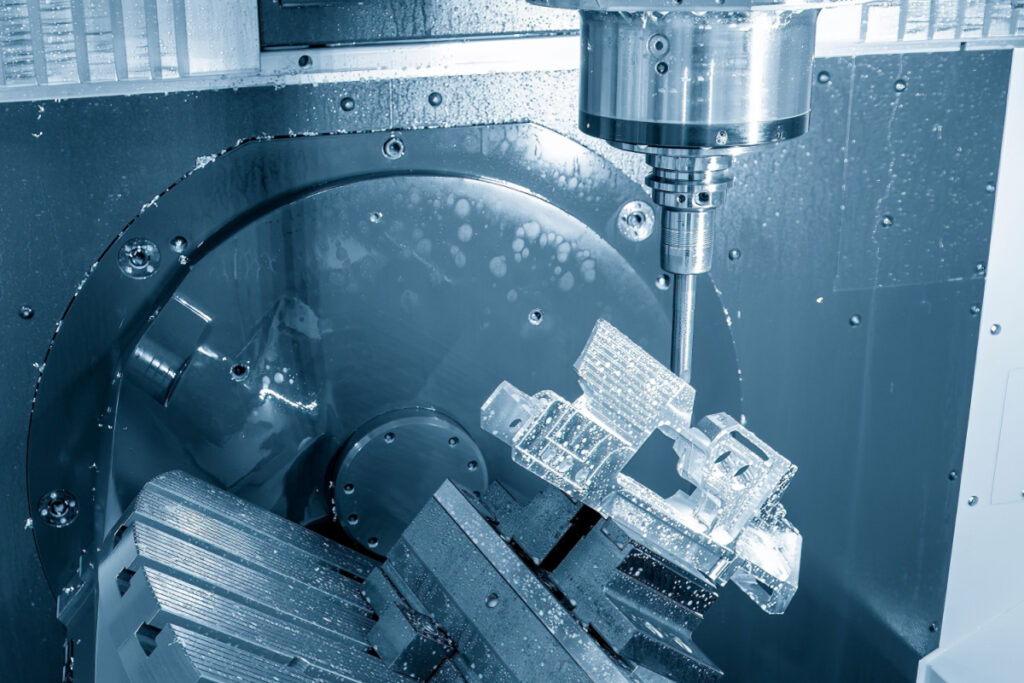

A typical 3 axis vertical CNC milling machine has x, y, and z, axes. Here is how they work:

- X – moves table side to side (where workpiece goes)

- Y – moves table forward and backward

- Z – contains the cutting tool which comes down on the workpiece.

2. What does a 3 axis machining center do?

As the cutting tool works, the table can move in one of four directions. 3 axis machining has many programming options and can make several cuts in secession. This gives the machine many programmable cutting functions.

3. What size capabilities do you offer for 3 axis machining work?

Our vertical CNC milling machine can handle pieces as wide as fifty inches and as long as twenty inches. We can do pieces as tall as twenty-five inches.

4. What kind of tolerances can be expected using three axis machining?

CNC 3 axis work can typically produce tolerances of .005 inches.

5. What are the advantages of 3 axis machining services?

With three axes you have a decided benefit over standard machines. With 2 axis work, the piece is stationary, and the cutting axis moves to make the cuts. 3 axis work lets the piece move forward, backward, or side to side as the machine cuts. This lets you make more intricate shapes and gives you many options.

6. Which industries benefit from 3 axis machining?

Our 3 axis milling and machining methods benefit a wide range of industries including:

- Oil and gas

- Medical

- Energy

7. How much does 3 axis machining cost?

Since projects vary greatly, it is best to call us at 1-573-646-3996 or visit our website quote section for an online quote.