Sustainability and environmental responsibility are not just ideals at Roberson Machine Company; they are our driving forces. Every team member in our machine shop actively pursues cleaner, more eco-friendly ways to manufacture your precision parts and products. As the aerospace industry moves forward at a rapid pace, you need a manufacturing partner that keeps up with the times in a sustainable fashion. You need Roberson Machine Company.

Give us a call today at 573-646-3996 or contact us online for all of your company’s aerospace machining needs and for a free quote. Let’s explore the vital role environment considerations play in our industry-leading aerospace machining.

Environmental Considerations in Aerospace Machining: What Does Roberson Machine Company Provide?

Energy-Efficient Practices

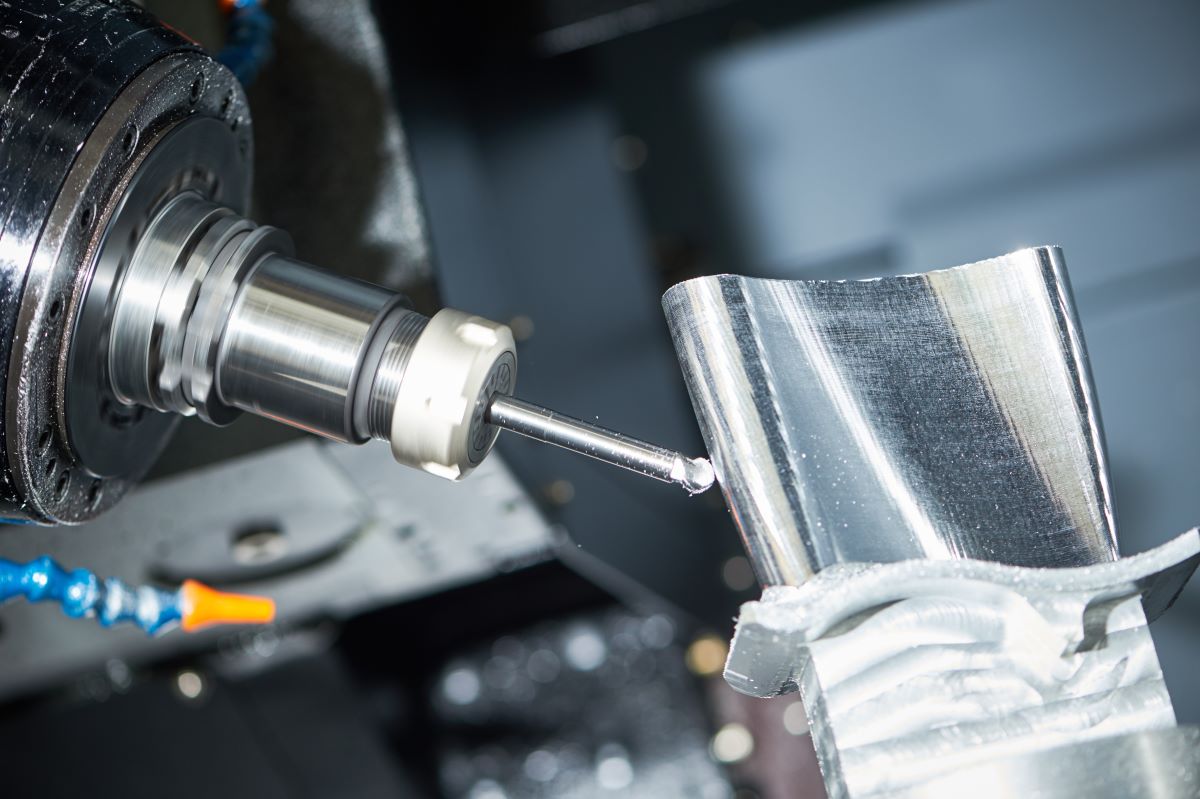

In our never-ending pursuit of sustainable aerospace machining, energy efficiency takes center stage in our shop. Using advanced technologies and machinery that optimize energy consumption contributes to reducing the overall carbon footprint. This is at the core of our aerospace machining services, as well as all of our machining methods. We use energy-efficient CNC machines and are constantly implementing smart manufacturing processes, like our robotic machine tending and 3D printing.

Eco-Friendly Machine Coolants

Coolants play a crucial role in aerospace machining, ensuring machine and tool longevity, as well as maintaining precision. But some traditional coolants produce mists that, while often invisible to the naked eye, can cause occupational dermatoses and other severe health conditions. We use only environmentally friendly cooling options in our machines and throughout our shop. This reduces the ecological impact and guarantees a safer working environment.

Call us right away at 573-646-3996 or contact us online for your free quote.

Materials Matter

From high-strength alloys and titanium to composites and high-performance plastics, aerospace machining involves working with a diverse range of materials and workpieces. We always choose sustainable material alternatives that do not compromise on performance or precision.

Waste Reduction

Precision machining at Roberson Machine Company inevitably generates waste, but we do whatever it takes to minimize our environmental impact. Our stringent internal standards include:

- Adopting lean manufacturing principles

- Implementing efficient recycling programs for our metal shavings, coolants, and other byproducts

- Moving toward a circular economy practice

Life Cycle Assessments

We conduct thorough life cycle assessments (LCAs) from initial prototypes to end-of-life considerations. This approach evaluates the environmental impact at every stage of a component’s life, helping identify areas for improvement, sustainability, and innovation. LCAs guide every party’s decision-making toward more sustainable choices in materials, processes, and disposal methods.

Environmental Considerations in Aerospace Machining: What Are the Benefits?

Environmental considerations in our aerospace machining bring about several benefits. Some of these are:

- Customer Preference: Many individuals and businesses prioritize environmentally responsible manufacturing. We recognize that we have gained a competitive edge in the market as we attract environmentally conscious partners.

- Cost Savings: By implementing the sustainable practices listed above, we can reduce our operating costs over time and pass along the savings to our customers.

- Reduced Carbon Footprint: Utilizing eco-friendly machining practices helps minimize carbon emissions and lowers the overall environmental impact of our aerospace machining services.

- Resource Conservation: Efficient use of materials and workpieces – as well as energy conservation in machining processes – contributes to the responsible use of resources, reducing waste and minimizing environmental depletion.

- Employee Morale: Our commitment to environmental responsibility boosts employee morale. Our team members take pride in working in an environment that values both their safety and overall sustainability, contributing to a positive and efficient workplace culture.

Environmental Considerations in Aerospace Machining | Roberson Machine Company

As the aerospace sector continues to grow, the importance of environmental considerations in machining cannot be overstated. We embrace a commitment to sustainability, integrating eco-friendly practices into our operations, and contributing to a greener future inside and outside of our shop. We are helping shape a sustainable tomorrow.

Call Roberson Machine Company now at 573-646-3996 or contact us online to get a free quote for your company’s next aerospace machining parts project.