CNC Methods That Drive Part Production

Different parts demand different machining strategies. At Roberson Machine Company, we align CNC (computer numerical control) methods that drive part production to match your materials, geometries, and run sizes to meet production goals.

Read on to learn more about:

- Primary CNC methods used in part production

- Types of components produced in large production runs

- Industries that rely on CNC part production

- How the Roberson Machine Company can help

You can contact us online or give our our team a call at 573-646-3996 for more information about custom CNC machining and part production.

4 Core CNC Methods That Drive Part Production

Every part starts with the right method. Whether it’s precision-milled surfaces, turned components, or intricate EDM features, we’ll apply the most efficient CNC approach for consistent output at scale. Below are the core CNC machining methods that keep production moving with efficient workflows.

These methods don’t exist in isolation—they often work in sequence or combination depending on the production stage and part requirements.

1. CNC Milling

CNC milling covers aluminum housings, heat sinks, brackets, covers, and more. These machines can cut multiple sides and features in one setup to reduce changeovers and keep throughput high. Aerospace, automotive, and other industries that rely on parts automation lean on high-speed milling for steady, repeatable runs.

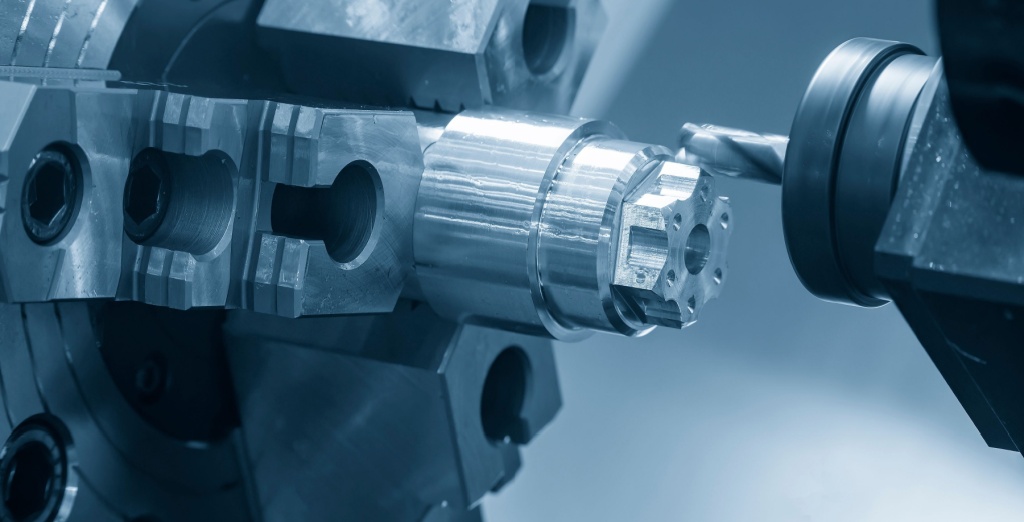

2. CNC Turning

CNC turning handles round and cylindrical components that form the backbone of most production runs. Automated bar feeders and sub-spindles support continuous cutting, while live tooling adds milled features without extra setups or changeovers.

Shafts, bushings, rollers, and couplings all benefit from fast cycle times and reliable repeatability—making turning essential for part production.

Capabilities include:

- Hard turning

- Long turning up to 48 inches in length

- Tight tolerances

- Short lead times

Traditional lathe machines use two axes and a single spindle to shape parts along a fixed centerline. A modern CNC turning center expands that concept with multiple spindles, tool turrets, and live tooling, letting us complete complex parts in one continuous cycle without disrupting the production run.

3. Multi-Axis Machining

Multi-axis machining combines speed and flexibility. By machining several sides in one operation, it cuts repositioning and setup time while supporting complex ports, angles, and compound surfaces.

3-, 4-, and 5-axis CNC machining allow multi-stage production cycles to run efficiently without stopping for manual changeovers, keeping part consistency and volume targets on track.

4. Wire EDM

Wire EDM (Electrical Discharge Machining) uses a charged wire to cut conductive materials with extreme precision. It’s ideal for hardened steels, titanium, and other alloys that are difficult to machine conventionally.

Because the process removes material without contact, parts stay free from burrs, warping, or thermal distortion—critical for thin walls, small radii, tight corners, and complex internal features. Wire EDM also minimizes tool wear, reduces secondary finishing, and maintains integrity through long production runs.

Common Components for High-Volume Part Runs

Certain components lend themselves to repeatable, high-volume production more than others. These parts share stable geometries, standardized features, and predictable material behavior that align well with CNC milling, turning, EDM, and the multi-axis workflows discussed above.

Common use cases include:

- Rollers and pulleys

- Manifolds and valve bodies

- Crankshaft spacers

- Lids, enclosures, and covers

- Robotic tooling adapters

- Aluminum housings

- Brackets and mounting plates

- Heat sinks and thermal plates

- Shafts and pins

- Bushings and spacers

- Enclosures and instrument frames

- Sensor and connector hardware

These core parts and housings are foundational for more complex assemblies that require repeatability and efficiency at scale.

Industries That Rely on CNC Part Production

- Aerospace

- Military and Defense

- Automotive and EV

- Medical Devices and Pharmaceuticals

- Industrial Automation and Robotics

- Energy (oil and gas, power generation, renewables)

- Electronics and instrumentation

- Agriculture and heavy equipment

- Food and Beverage

- Other Industries

You can see how we’ve helped clients achieve high-efficiency production runs in our case studies.

Why Roberson Machine Company for Part Production?

Achieving consistency and CNC precision in CNC production is possible with the right equipment, planning, and skillset. With more than 20 years of machining experience, Roberson Machine Company is here to help bring your project into full-scale production. Contact us online or call 573-646-3996 to learn more about our capabilities and the CNC methods we use to drive part production.