If you run a small to medium size machine shop or manufacturing service, you may be thinking about upgrading. For example, CNC machines give you many advantages, but when you upgrade to multiple axis machines, you increase your capabilities even more. Here are some good reasons to consider 5 axis machining for your business.

What Does 5 Axis Mean?

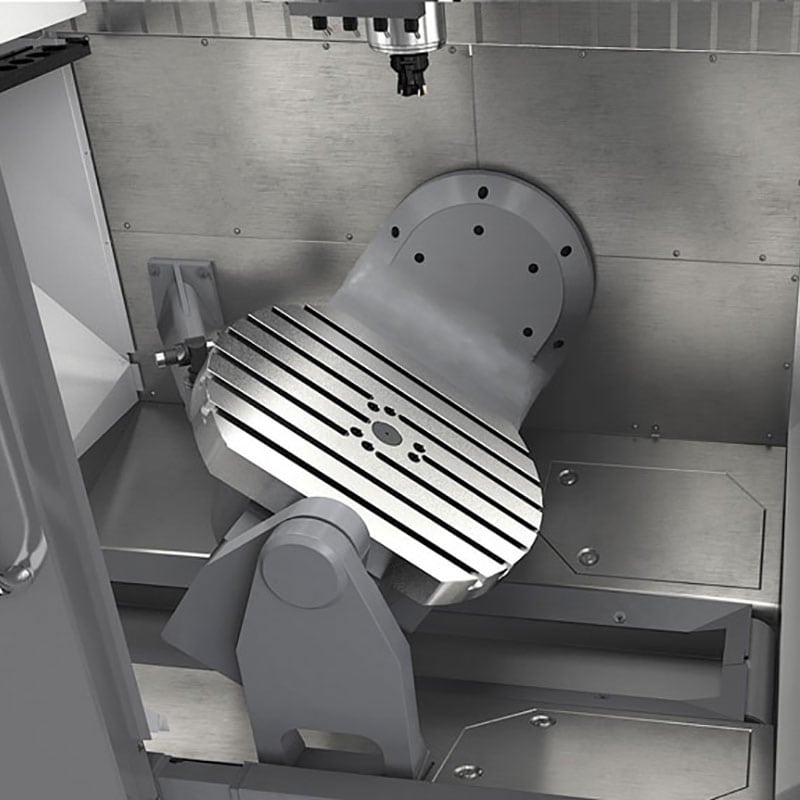

With a three-axis machine, the workpiece can move in two directions, and the work tool moves in one direction. When you have five axes, you have the benefits of a three-axis machine, but you can approach the workpiece from two additional angles.

More Complicated Work

With 5 axis machining, you can do more complex work than before. For example, once programmed, you can do three-dimension milling projects in all shapes and sizes. In fact, this kind of machine is perfect for creating prototypes, to help you bring new and improved parts or products to market and expand your business.

Time-Saving

When you approach your work from many angles, you lessen the time it takes to complete a project. There’s no need to stop and re-tool the machine or take it to another workstation to complete the job. Because all the work is automated, you save a lot of time creating parts. This is important for intricate tasks like molds for medical devices or automotive parts.

What about the Cost?

If you’re a small shop or service, 5 axis machining may not be in your budget this year, but that’s fine. Thanks to machining services like Roberson Machine Company you don’t have to invest money in expensive machinery or figure out a way to fit more equipment into your facility. We are set up to handle many machining tasks and offer fast turnaround times. Call us today at (573) 646-3996 to see what we can do for you.