Move prototypes into volume with Custom CNC Machining for Part Production in Tallahassee, FL from Roberson Machine Company. We help you improve efficiency, reduce waste, and run custom CNC machining for high-volume part production. Contact us online or call 573-646-3996 to learn more about Tallahassee, FL, custom CNC machining for mass part production.

Get to know more about:

- Why companies choose custom CNC machining for part production at scale

- Key benefits (repeatability, stable unit cost, fast ramp to volume, and documentation)

- Industries that depend on high-volume CNC machining for consistent parts

- Components that repeat well across production runs

- How to get started with a quote for mass part production

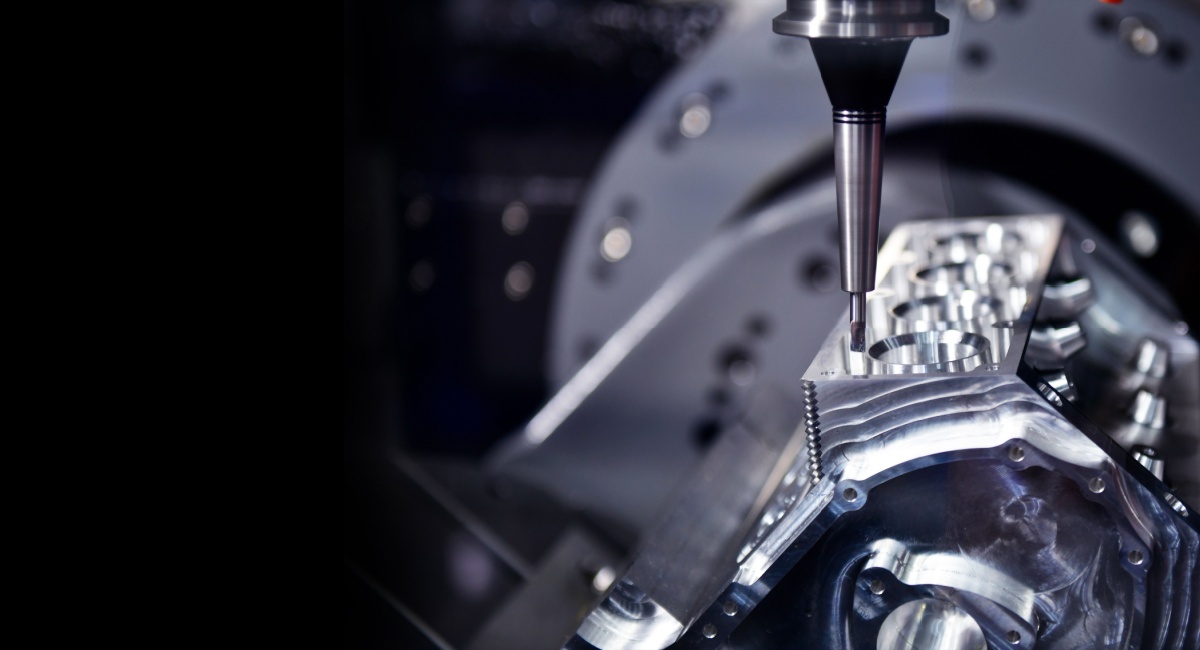

Need thousands of consistent parts? CNC machining delivers speed and quality at scale. It spans supply-line management, rigorous in-process and final inspections, and a reliable supplier who turns concepts into production-ready assets. With 20+ years of results, our team leverages precision CNC machining and automation to improve processes, back your supply chain, and maintain quality for high-volume CNC part production in Tallahassee, FL.

Table of Contents

- Why Companies Choose CNC Machining for Tallahassee, FL, Part Production

- Industries That Depend on Custom CNC Machining for Part Production

- Common Part Categories for Production

- How to Get Started with Custom Tallahassee, FL, CNC Machining for Part Production

- What You Gain with Production-Grade CNC

- Frequently Asked Questions

- Why Choose Roberson Machine Company

See how production performs in our reviews and case studies, and read more on part production and CNC machining via the blog and FAQs.

Why Tallahassee, FL, Companies Choose CNC Machining for Part Production

High-volume product runs only work when every lot matches. With CNC machining, workflow automation, and rigorous QA across the production cycle, we lock fixtures, tool paths, and in-process checks so volume stays on spec and costs stay predictable.

When the process scales, you can expect:

- Repeatability at Volume: Proven setups and probing maintain locations, finishes, and stack-ups from lot to lot.

- Stable Unit Cost: Controlled cycle times and managed tool life keep pricing steady as quantities rise.

- Shorter Ramp to Volume: Once dialed in, runs repeat without additional process changes.

- Broad Material Capability: We handle aluminum, carbon and alloy steels, stainless, titanium, and production-grade polymers at production volumes using the same locked process.

- Documentation and Traceability: Inspection results, lot traceability, and shipment information are provided as required.

With fixtures, tool paths, and inspection set, custom CNC machining in Tallahassee, FL, makes part production repeatable at scale.

Tallahassee, FL, Industries That Depend on Custom CNC Machining for Part Production

When you need thousands of identical parts, production-grade CNC keeps quality steady and unit costs predictable. We build stable solutions for fixtures, tool paths, tool life management, and in-process inspection that hold dimensions from the first article through every shipment.

The value shows up across every industry. With a locked setup and defined checks, our solutions are designed to deliver the same part every run, so planning and pricing stay predictable as volumes rise.

Common industries that use CNC machining for large-scale Tallahassee, FL, production runs include:

- Aerospace

- Military and Defense

- Automotive and EV

- Medical Devices and Pharmaceuticals

- Industrial Automation and Robotics

- Energy (oil and gas, power generation, renewables)

- Electronics and instrumentation

- Agriculture and heavy equipment

- Food and Beverage

- Other Industries

Common Part Categories for CNC Parts Production in Tallahassee, FL

These are components that scale and repeat well across industries:

- Housings and covers

- Brackets, plates, and mounts

- Shafts, pins, and bushings

- Manifolds and valve bodies

- Enclosures and panels

- Heat sinks and thermal plates

- Gears, pulleys, and rollers

- Fixtures and tooling components

- Sealing and mating surfaces

- Medical parts and instrument components

- Sensor and instrumentation hardware

As one example from the medical industry, we’ve produced a valve body featuring precise passage geometry and deburr control, plus microscope components and acrylic instrument parts.

In other sectors, we’ve produced ink rollers for packaging lines (finish and concentricity at volume), along with end-of-arm robot tooling parts, drive shafts, and more.

For parts like these, production-grade CNC delivers consistent dimensions and finishes at volume while keeping per-unit cost steady.

Let’s finalize production schedules, keep unit cost stable, and maintain quality with documented backups. Get in touch with our custom CNC part production team online or call 573-646-3996 for more info.

How to Get Started with Custom CNC Machining for Part Production in Tallahassee, FL

Few projects are ready for full-scale CNC part production right away. If specifications are still evolving, send us what you have and we’ll close the gaps. Drawings, tolerances, material and finish goals, expected volume and delivery cadence, must-hold features, plus packaging or documentation needs are all we need to quote and map production.

With a complete package, we move straight into scheduling. Without it, we’ll follow up for the remaining details to finalize the production cycle and pricing.

What You Gain with Production-Grade CNC Machining

Repeatable results at volume: fewer changeovers, higher first-pass yield, predictable per-unit cost, steady schedules, clean revision tracking, and documentation when needed, without reworking the process run after run.

Frequently Asked Questions

If you’re managing budgets and releases, the real questions usually aren’t about cutting metal — they’re about price, schedule, and repeatability. These FAQs address the details that matter when shifting from prototype to production-grade CNC machining.

What does “production-grade” CNC machining mean?

Process locked for volume—fixtures, tool paths, tool life management, and inspection routines—repeating lot after lot without shifts in quality or cost.

What do you need to quote a production run?

Drawings with tolerances, finish and material details, expected volumes, and delivery cadence cover the basics. Supplying documentation or packaging requirements (PPAP, certs, labels, etc.) in advance helps us lock schedules quickly.

What actually pushes lead time out?

Common causes of delay include long-lead materials, fixture builds, added inspections, and design changes during production. Clear specs plus early choices on finishes, docs, and packaging keep schedules on track.

How do you hold repeatability across large lots?

We standardize fixturing, control tool wear, and verify critical features with probing and CMM checks. The process is built to hold dimensions from the first article to the last shipment.

What’s typical lead time for first article vs. repeat runs?

Fixtures, material, and the inspection plan drive first-article timing. Once approved, repeat lots move on a fixed schedule matched to your release cadence.

Is there a minimum order quantity?

MOQs depend on setup and cycle time. We return quotes with per-lot and annual breaks to help you balance unit price against inventory and release cadence.

Why Choose Roberson Machine Company for Tallahassee, FL, Custom CNC Part Production?

With Roberson Machine Company, you gain a production partner who understands scaled manufacturing. This includes:

- Processes locked for volume, including fixtures, proven tool paths, tool life control, and in-process inspection

- Capacity planning with predictable releases matched to your run’s forecast

- Inspection data, lot traceability, and shipment records supplied on request

- Value-added services that tighten up finishing, assembly, and packaging

- Competitive pricing and consistent lead times

These services support custom CNC part production in Tallahassee, FL:

- CNC Lathe Machining

- CNC Machine Automation

- Oil and Gas Precision Machining

- Aerospace Manufacturing

- Automotive Part Manufacturing

- EDM Machining

- High Volume CNC Machining

- Industrial Automation

- Solar Panel Manufacturers

Roberson Machine Company brings scalable part production to life with automated CNC machining. Learn about our team and capabilities, request a quote, or call 573-646-3996 to talk through upcoming releases and volume goals for custom CNC machining for part production in Tallahassee, FL.